Honeywell SPS series intelligent position sensor

Design features: Adopting non-contact design, eliminating mechanical failure mechanisms, reducing wear and tear, improving reliability and durability, and reducing downtime.

Core function: Used for absolute position detection, using patented combination technology (ASIC dedicated integrated circuit+MR magnetic resistance sensor array) to accurately and reliably detect the position of magnets attached to moving objects, thereby determining or controlling the position of the object.

Detection principle: The MR array measures the output of MR sensors installed along the direction of magnet motion, determines the pair of MR sensors closest to the center of the magnet through the output and MR sensor sequence, and then uses the outputs of these two sensors to determine the position of the magnet between them.

Output type: Provides analog output with 3 different detection range configurations, namely 0-35mm (0-1.38 inches), 0-75mm (0-2.95 inches), and 0-225mm (0-8.86 inches).

Honeywell SPS series intelligent position sensor

Product Description

Positioning: A durable, adaptable, and lightweight linear position sensor in the industrial field that can achieve high-precision motion control, improve operational efficiency and safety.

Design features: Adopting non-contact design, eliminating mechanical failure mechanisms, reducing wear and tear, improving reliability and durability, and reducing downtime.

Core function: Used for absolute position detection, using patented combination technology (ASIC dedicated integrated circuit+MR magnetic resistance sensor array) to accurately and reliably detect the position of magnets attached to moving objects, thereby determining or controlling the position of the object.

Detection principle: The MR array measures the output of MR sensors installed along the direction of magnet motion, determines the pair of MR sensors closest to the center of the magnet through the output and MR sensor sequence, and then uses the outputs of these two sensors to determine the position of the magnet between them.

Output type: Provides analog output with 3 different detection range configurations, namely 0-35mm (0-1.38 inches), 0-75mm (0-2.95 inches), and 0-225mm (0-8.86 inches).

Product Features

Specific content of characteristic categories

Reliable non-contact design reduces wear and tear, improves reliability and durability, and reduces downtime; Equipped with self diagnostic function, it can provide predictive maintenance input, further reducing equipment downtime

Easy to install installation only requires 4 simple steps: positioning sensor → drilling → installing sensor → positioning magnet actuator/electrical connection

The robust sensor has no moving parts inside and uses unique packaging materials that are resistant to vibration, impact, and extreme temperatures; Equipped with IP67 and IP69K protection levels, it can be used in various harsh environments; The 35mm configuration complies with automotive grade EMI/EMC specifications and can resist environmental frequency interference

The flexible air gap range is large (the air gap for 35mm configuration reaches 8.5 ± 1.0mm, and the air gap for 75mm and 225mm configurations is 3.0 ± 2.5mm), expanding the application scenarios; Provide multiple output options (standard analog output); Onboard electronic components support flexible packaging and are compatible with existing system components; The sensor array is easy to configure and can adapt to almost all linear motion paths

High precision varies with different configurations: the minimum measurement value for the 35mm configuration is 0.04mm (0.0016 inches), for the 75mm configuration it is 0.05mm (0.002 inches), and for the 225mm configuration it is 0.14mm (0.0055 inches) (analog output)

Compared to LVDT (Linear Variable Differential Transformer) technology, lightweight reduces weight by more than 50%

Environmental compliance adopts materials that comply with RoHS standards and meet the 2002/95/EC directive

Product specifications (detailed by configuration)

1. 35mm configuration (analog type: SPS-L035-LATS)

Specification category parameter details (Min. Min. Typ. Typical Max. Maximum)

Sensor characteristic detection range: 0-35mm; power supply voltage: 4.75-5.525VDC; Power supply current: maximum 20mA; output type: ratio formula; Minimum position output: 0.6Vdc; Maximum position output: 4.2Vdc; Full range span: 3.6Vdc; Sensitivity: 102-103-104mV/mm; Linearity: ± 1.0% full-scale output; Resolution: 40 μ m; Update rate: 476 μ S; Reverse polarity: -5V; startup time: 5mS

Connector termination method: Tyco Super seal 282087-1 integrated connector; Cable bending radius: No relevant data available (n/a)

Working environment working temperature: -40 ° C to 125 ° C (-40 ° F to 257 ° F); Storage temperature: -40 ° C to 150 ° C (-40 ° F to 302 ° F); Air gap: 8.5 ± 1.0mm (0.334 ± 0.039 inches); Protection level: IP67, IP69K; Radiation immunity: compliant with ISO 11452-2 standard, 100V/m; Conducted immunity: compliant with ISO 11452-4 standard, 100mA BCI; Mechanical shock: 50G half sine wave, continuous for 11ms; Vibration: 10Hz to 2000Hz, 20G

Certification CE, UKCA

Installation shell: thermoplastic; Installation screws: 1/4-20 or M6; installation torque: 6-10Nm (53.1-88.5 inch pounds)

Recommended magnet type: neodymium iron boron; Magnetic field strength: 13500 Gauss

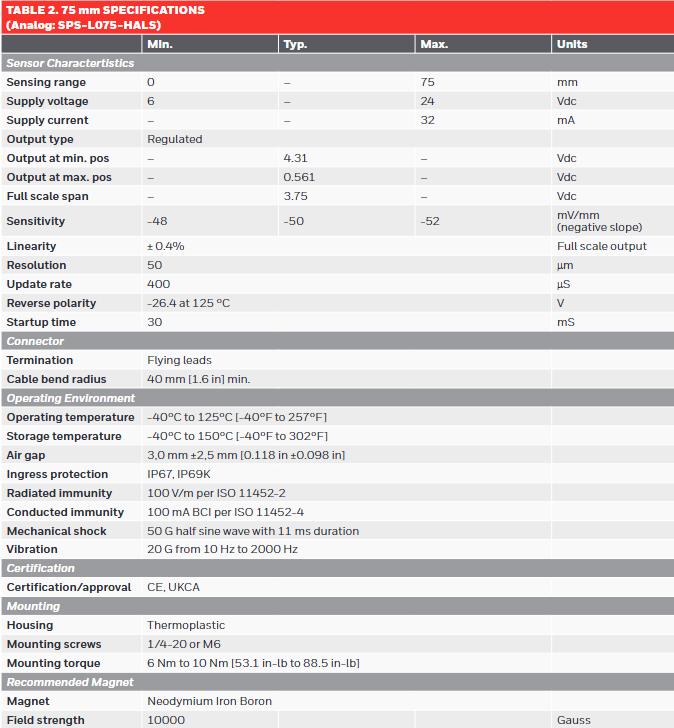

2. 75mm configuration (analog: SPS-L075-HALS)

Specification category parameter details

Sensor characteristic detection range: 0-75mm; power supply voltage: 6-24Vdc; Power supply current: maximum 32mA; output type: stabilized voltage type; Minimum position output: typical 4.31VDC; Maximum position output: typical 0.561Vdc; Full range span: typical 3.75VDC; Sensitivity: -48 to -52mV/mm (negative slope, typical -50mV/mm); Linearity: ± 0.4% full-scale output; Resolution: 50 μ m; Update rate: 400 μ S; Reverse polarity: 26.4V at 125 ° C; Start time: 30mS

Connector termination method: Flywire; Cable bending radius: minimum 40mm (1.6 inches)

The working environment, storage temperature, protection level, radiation immunity, conducted immunity, mechanical shock, vibration parameters are consistent with the 35mm configuration; Air gap: 3.0 ± 2.5mm (0.118 ± 0.098 inches)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands