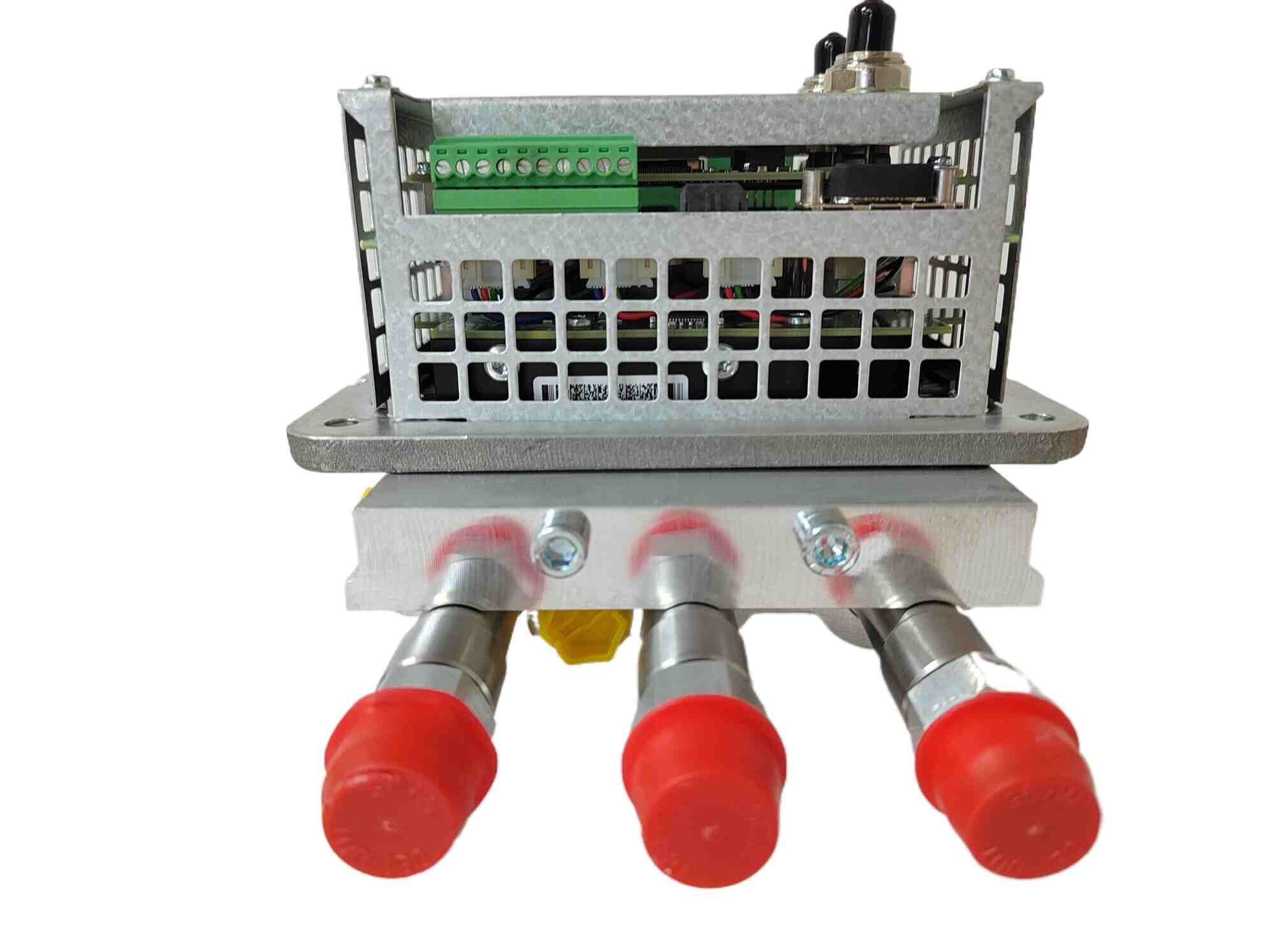

ABB UNS0119A-P V101 Controller Module

ABB UNS0119A-P V101 Controller Module

Brand background

In the field of industrial control and electrical engineering, ABB is undoubtedly an insurmountable monument. Since its birth in 1988 through the merger of ASEA and BBC, ABB has always adhered to the spirit of innovation and deeply cultivated globally. From being the first to launch a three-phase transmission system and ushering in a new era of power transmission, to developing the world's first self cooling transformer to revolutionize power equipment, ABB's technological innovations continue to reshape the industry landscape. Nowadays, ABB, with operations spanning over 100 countries and 132000 employees, has established a complete technology and service system in various fields such as power and industrial automation. Its profound technical accumulation and excellent brand reputation have laid a solid foundation for the birth and application of the UNS0119A-P V101 controller module.

Product Core Overview

The ABB UNS0119A-P V101 controller module, as an important member of ABB's industrial automation product line, is an intelligent control device that combines advanced technology and high reliability. It is carefully designed for various complex industrial environments, capable of accurately and efficiently handling diverse control tasks, and plays a central nervous system like key role in industrial automation control systems. Through precise control and collaborative scheduling of various devices, this module helps enterprises improve production efficiency, ensure product quality, and promote industrial production towards intelligence and refinement.

Core functions

Super computing and decision-making capabilities: The UNS0119A-P V101 is equipped with an advanced microprocessor, which has high-speed data processing and complex logic computing capabilities. It can collect and analyze massive amounts of data from on-site devices such as sensors and actuators in real time, and make precise decisions and generate corresponding control instructions in a very short time based on preset control algorithms, ensuring that various parameters in the industrial production process are always maintained within the ideal range, providing solid guarantees for the stability and efficiency of production.

Multi communication interaction function: The controller module is equipped with rich communication interfaces, among which the Ethernet interface can easily access the internal network of the enterprise and achieve high-speed data exchange with the upper computer monitoring system, PLC and other devices. Engineers can remotely monitor the module's operating status and adjust control parameters in real time. The RS485 interface provides the possibility for it to connect with numerous smart instruments and devices that support Modbus RTU protocol, easily achieving interconnection and intercommunication between devices, and building a comprehensive and efficient industrial automation communication network.

Flexible I/O configuration capability: In terms of I/O ports, a large number of digital input and output ports can quickly respond to switch signals, used for basic operations such as controlling the start stop and status monitoring of equipment, such as controlling the forward and reverse rotation of motors, detecting the operation/stop status of equipment, etc. The analog input and output ports are dedicated to processing continuously changing signals, such as temperature, pressure, flow rate, and other analog parameters. The module can accurately collect and output analog signals, finely adjust related equipment, and meet the diverse signal processing and control requirements in industrial production.

Convenient programming and customization features: Supports multiple industrial standard programming languages, such as ladder diagrams, structured text, etc., making it easy for engineers skilled in graphical programming or professionals accustomed to text programming to get started. With the visual programming software provided by ABB, users can complete module configuration, parameter setting, and program writing through an intuitive graphical interface, greatly reducing programming difficulty and improving development efficiency. More importantly, users can flexibly adjust module functions and parameters based on actual production processes and control requirements, achieve customized control solutions, and make the controller module perfectly adapt to various complex application scenarios.

Working principle

When UNS0119A-P V101 is put into operation, firstly, various signals from the on-site equipment will be continuously transmitted to the controller module. The analog signals such as temperature and pressure detected by sensors, as well as the digital signals generated by buttons, limit switches, etc., enter the module through corresponding input interfaces. The analog signal is converted into a digital signal by a high-precision analog-to-digital converter inside the module, and then sent to the microprocessor together with the directly input digital signal. The microprocessor performs deep analysis, complex calculations, and precise judgments on these input signals based on pre written and stored control programs and algorithms in memory. After processing, the microprocessor outputs the generated control instructions in the form of digital signals. To control analog actuators such as regulating valves, frequency converters, etc., digital signals need to be converted into analog signals through a digital to analog converter before being transmitted to the actuator; If controlling digital actuators such as relays, contactors, etc., digital signals are directly output to drive their actions. In addition, throughout the entire control process, the controller module continuously exchanges data with other devices through communication interfaces to achieve information sharing and collaborative operations, thereby ensuring the stable and efficient operation of industrial automation systems.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands