Rockwell 1746-IB32 Digital Input Module

Typical application scenarios: Widely used in manufacturing production lines, mechanical equipment control, process automation and other fields, such as assembly line workstation status detection, motor start stop signal acquisition, safety door switch status monitoring, etc.

Rockwell 1746-IB32 Digital Input Module

Product basic positioning

Model attribution: 1746-IB32 is a digital input module of Rockwell Automation SLC 500 series programmable logic controller (PLC), mainly used for collecting discrete switch signals (such as on/off signals output by sensors, buttons, limit switches, etc.) in industrial sites, and converting them into digital signals recognizable by PLC to achieve real-time monitoring of equipment status.

Typical application scenarios: Widely used in manufacturing production lines, mechanical equipment control, process automation and other fields, such as assembly line workstation status detection, motor start stop signal acquisition, safety door switch status monitoring, etc.

Core technical specifications

(1) Input characteristics

Specification category reference parameter description

The single module supports 32 independent digital input channels and can simultaneously collect 32 switch signals. The channels are electrically isolated to avoid signal interference

The input signal type is direct current (DC), which usually supports two common industrial DC voltages: 24V DC or 120V DC (please refer to the official document for details), and is compatible with NPN or PNP sensor outputs

Input response time ≤ 1ms (typical value) to quickly respond to on-site signal changes, ensuring real-time control logic, suitable for scenarios with high response speed requirements

Low power design with input current of 7mA~10mA (per channel), reducing overall system energy consumption, and compatible with the output current range of most industrial sensors

(2) Electrical and Protection

Isolation method: Adopt channel to channel optoelectronic isolation or group isolation (such as isolation every 8/16 channels), with isolation voltage usually ≥ 250V AC (1 minute), effectively suppressing electromagnetic interference (EMI) and grounding loop problems in industrial sites.

Overvoltage/Overcurrent Protection: Some models have built-in overvoltage protection circuits (such as transient voltage suppressors TVS) and overcurrent protection (such as self recovery fuses) to prevent module damage from abnormal voltage/current on site.

(3) Physics and Installation

Dimensions: Suitable for SLC 500 series standard racks (such as 1746-A7/A10, etc.), usually designed as a "thin module", with a width of about 32mm, a height matching the rack (about 100mm), and a depth of about 160mm (subject to official data), saving rack installation space.

Installation method: It is installed using DIN rails or directly fixed on the SLC 500 rack backplane. During installation, it is necessary to ensure that the module is reliably connected to the rack bus to ensure stable data transmission and power supply.

(4) Environmental adaptability

Working temperature: -20 ℃~60 ℃ (industrial standard), can operate stably in high and low temperature industrial environments, such as workshops, warehouses, outdoor control cabinets, and other scenarios.

Humidity range: 5%~95% RH (non condensing), suitable for humid environments, no additional moisture-proof measures required (requires overall protection of the control cabinet).

Protection level: The protection level of the module itself is usually IP20 (for panel installation), and it needs to be installed in a closed control cabinet to avoid direct contact with dust and liquids.

Functional characteristics (based on the commonality of SLC 500 series modules)

Diagnostic function: Supports channel level fault diagnosis, such as open circuit and short circuit detection. Diagnostic information can be read through PLC programming software (such as RSLogix 500) to quickly locate the faulty channel and reduce troubleshooting time.

Compatibility: Fully compatible with all SLC 500 series CPU modules (such as 1747-L511/L532, etc.), can be mixed with digital output modules (such as 1746-OB16) and analog modules (such as 1746-NI8) of the same series for installation, and build a complete control system.

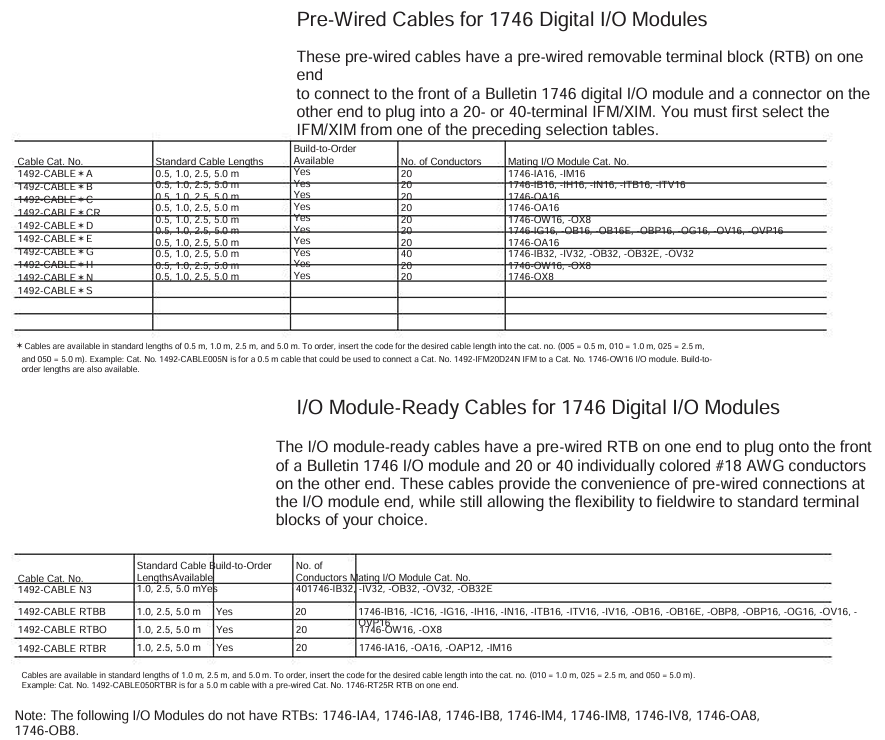

Wiring method: Adopting a detachable terminal block (such as 1746-TB32 terminal board), supporting "front wiring" or "rear wiring", the wiring operation is convenient, and the terminal block can be directly disassembled for later maintenance without dismantling the entire module.

Precautions for use

Power supply requirements: The module is powered by the SLC 500 rack backplane (usually a 5V DC logic power supply+24V DC input power supply). It is necessary to ensure that the rack power module (such as 1746-P2) outputs stably to avoid voltage fluctuations that may cause module failures.

Signal wiring: Input signal lines should be routed separately from power lines (such as motor cables) to reduce electromagnetic interference; When wiring for long distances (over 100m), shielded twisted pair cables should be selected and properly grounded.

Module address setting: If multiple modules of the same type are installed in the rack, a unique address needs to be set through the address dip switch on the module to ensure that the PLC can correctly identify each module channel.

Software configuration: In RSLogix 500, it is necessary to correctly configure the module type (select "1746-IB32") and input filtering time (which can be set according to the on-site interference situation, such as 0.1ms~10ms) to avoid false triggering caused by high-frequency interference.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands