Welcome to the Industrial Automation website!

Product

Article

NameDescriptionContent

GE Digital Energy Hydran 201Ti Transformer DGA Monitor

The HydranTM 201Ti is a small and easy to setup continuous Dissolved Gas-in-oil Analysis (DGA) monitor.

It provides the basic information used by IEEE® Standard C57.104 and can be used as an essential first line of defence for the transformers in your fleet to obtain advance warning of a failure condition and minimize the risk of unplanned outages.

It provides the basic information used by IEEE® Standard C57.104 and can be used as an essential first line of defence for the transformers in your fleet to obtain advance warning of a failure condition and minimize the risk of unplanned outages.

GE Digital Energy Hydran 201Ti Transformer DGA Monitor

The HydranTM 201Ti is a small and easy to setup continuous Dissolved Gas-in-oil Analysis (DGA) monitor.

It provides the basic information used by IEEE® Standard C57.104 and can be used as an essential first line of defence for the transformers in your fleet to obtain advance warning of a failure condition and minimize the risk of unplanned outages.

The 201Ti’s composite-gas sensor provides the world renown “Hydran gas value” using fuel cell technology (described as fixed instruments - method 3 in the standard). It responds 100% to Hydrogen(general fault gas) and is also sensitive to Carbon Monoxide (overheated paper), Acetylene (arcing) and Ethylene (overheated oil), thus covering all the main transformer failure root causes.

Because the monitoring unit mounts on a single valve and uses Dynamic Oil Sampling, there is no need for a pump or extra piping to connect to different valves. Due to its uncomplicated features and the easily understood information it provides, the 201Ti has been amongst the monitors of choice for many years, with one of the largest installed base of any monitor.

With the latest Mark IV version, the Hydran 201Ti monitor has been completely overhauled with new electronic boards and power supply to make it RoHS compliant, address any obsolescence issue and further improve this time proven product

It now offers additional features like:

• Improved sensor

• Modbus® protocol communication over isolated RS-485

• Local USB port to replace the RS-232 port no longer found on most field laptops

• Compatibility with GE’s acclaimed PerceptionTM Fleet software to download,trend and analyse data,like with any other GE DGA monitoring equipment

Key Benefits

• Continually measures main H₂ fault gas

• Local LCD display

• Communicates gas ppm value remotely

• Proven and continuously improved design (over 30,000 units sold)

• Easy to install, single valve mount

Applications

Power Utilities

• Simple and effective solution for less-critical transformers

• Focuses and prioritizes asset replacement strategy

Industrial Plants

• Reduces the risk of process interruption due to power failure

• Minimizes costly production downtime

Easy Asset Supervision

• Permanently mounts on a single transformer oil valve. No extra piping or pump required

• Gas sensor responds 100% to Hydrogen(general fault gas) and is also sensitive to Carbon Monoxide (overheated paper)

• Optional 5 year sensor guarantee

Configurable Alarms

• An alarm is raised when an abnormal level of fault gas is detected

• Two alarm levels (one for Alert and one for Alarm) can be set to show increasing severity

• Alarms can be set on gas ppm levels or on gas rate of change (ROC) over an hour or a day

• Automatic self-test every 15 days will trigger service alarm if it detects a fault, including power failure, oil valve closed, sensor or battery needing replacement

Communication

• Local LCD display of the real-time dissolved gas ppm value

• Analogue output (4-20mA) of the dissolved gas ppm value

• Digital output of registers using Modbus or Hydran protocols over isolated RS-485

• 3 dry contact relays also available 2 for the fault gas alarms and one for the service alarm

Controllers

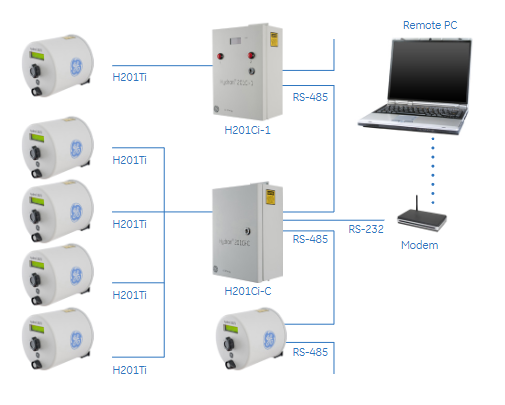

The 201Ti can be connected to optional controllers to facilitate communication with multiple units and create a local network.

• The Ci-1 controller is a one channel controller that replicates some of the human interface functions (gas value display, alarm buttons). This is ideal when the is mounted out of reach on an upper valve of the transformer. It also brings down the alarm relay contacts and the analogue output for easier wiring.

• The Ci-C controller receives the gas ppm data from up to four H201Ti, providing a single communication point for all four monitors. It has no alarm relay or analogue output. This is ideal when protecting 3 single phase transformers + 1 spare.It is possible to “daisy-chain” up to 32 controllers or 201Ti through their RS-485 port. The maximum chain distance (all cables added up) is 1200m (4000ft). All the 201Ti connected to any of the daisy-chained controllers can be accessed through any controller in the local network, thus facilitating communication by only having to fit one RS-232 modem for example.

Technical Specifications

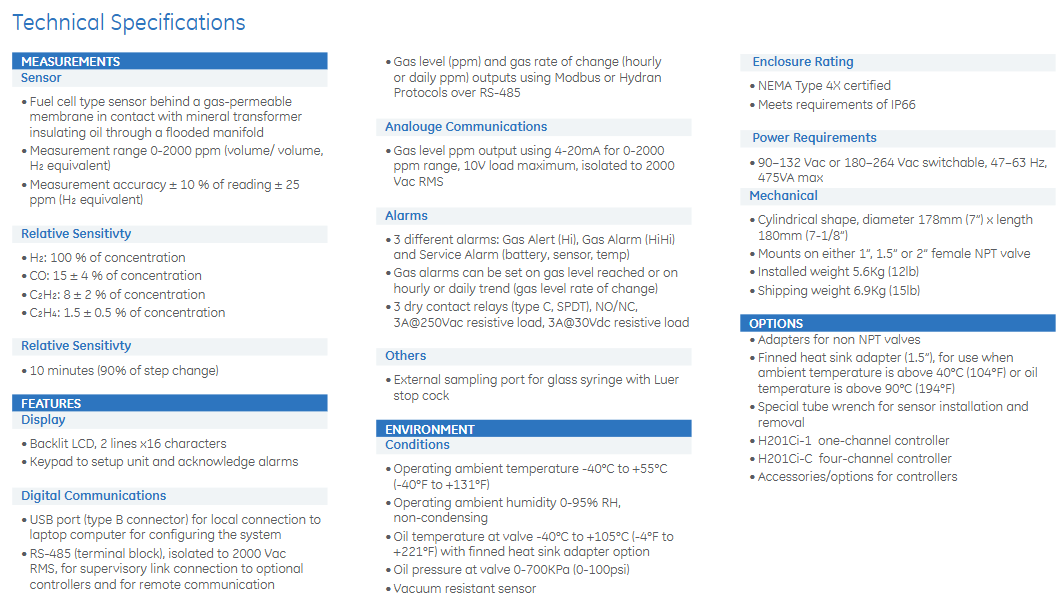

MEASUREMENTS

Sensor

• Fuel cell type sensor behind a gas-permeable membrane in contact with mineral transformer insulating oil through a flooded manifold

• Measurement range 0-2000 ppm (volume/ volume,H₂ equivalent)

• Measurement accuracy ± 10 % of reading ± 25 ppm (H₂ equivalent)

Relative Sensitivty

• H₂: 100 % of concentration

• CO: 15 ± 4 % of concentration

• C₂H₂: 8 ± 2 % of concentration

• C₂H₄: 1.5 ± 0.5 % of concentration

Relative Sensitivty

• 10 minutes (90% of step change)

FEATURES

Display

• Backlit LCD, 2 lines x16 characters

• Keypad to setup unit and acknowledge alarms

Digital Communications

• USB port (type B connector) for local connection to laptop computer for configuring the system

• RS-485 (terminal block), isolated to 2000 Vac RMS, for supervisory link connection to optional controllers and for remote communication

• Gas level (ppm) and gas rate of change (hourly or daily ppm) outputs using Modbus or Hydran Protocols over RS-485

Analouge Communications

• Gas level ppm output using 4-20mA for 0-2000 ppm range, 10V load maximum, isolated to 2000 Vac RMS

Alarms

• 3 different alarms: Gas Alert (Hi), Gas Alarm (HiHi) and Service Alarm (battery, sensor, temp)

• Gas alarms can be set on gas level reached or on hourly or daily trend (gas level rate of change)

• 3 dry contact relays (type C, SPDT), NO/NC,3A@250Vac resistive load, 3A@30Vdc resistive load

Others

• External sampling port for glass syringe with Luer stop cock

ENVIRONMENT

Conditions

• Operating ambient temperature -40°C to +55°C(-40°F to +131°F)

• Operating ambient humidity 0-95% RH,non-condensing

• Oil temperature at valve -40°C to +105°C (-4°F to +221°F) with finned heat sink adapter option

• Oil pressure at valve 0-700KPa (0-100psi)

• Vacuum resistant sensor

Enclosure Rating

• NEMA Type 4X certified

• Meets requirements of IP66

Power Requirements

• 90–132 Vac or 180–264 Vac switchable, 47–63 Hz,475VA max

Mechanical

• Cylindrical shape, diameter 178mm (7”) x length 180mm (7-1/8”)

• Mounts on either 1”, 1.5” or 2” female NPT valve

• Installed weight 5.6Kg (12lb)

• Shipping weight 6.9Kg (15lb)

OPTIONS

• Adapters for non NPT valves

• Finned heat sink adapter (1.5”), for use when ambient temperature is above 40°C (104°F) or oil temperature is above 90°C (194°F)

• Special tube wrench for sensor installation and removal

• H201Ci-1 one-channel controller

• H201Ci-C four-channel controller

• Accessories/options for controllers

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

66

+86-153-0592-5923

WeChat

Contact

wechat

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Eell:+86-153-0592-5923

Email:wang@kongjiangauto.com

Address:jiangxi District, China

Product

Copyright © 2023 KongJiang Group All Rights Reserved .