Allen-Bradley 2711P-RDT7C PanelView ™ Plus 6 700 Industrial Human Computer Interface

Allen-Bradley 2711P-RDT7C PanelView ™ Plus 6 700 Industrial Human Computer Interface

Product positioning and core identification

2711P-RDT7C is a PanelView from Rockwell Automation (Allen Bradley) ™ The 700 model industrial human-machine interface (HMI) display module under the Plus 6 series is designed specifically for industrial automation scenarios. Its core function is to achieve visual interaction between operators and automation systems (such as PLC, frequency converter), support equipment monitoring, parameter setting, data recording and other operations, and is widely applicable to small and medium-sized equipment in discrete manufacturing (such as machine tools, assembly lines), process control (such as chemical engineering, water treatment) and other fields.

Core hardware specifications

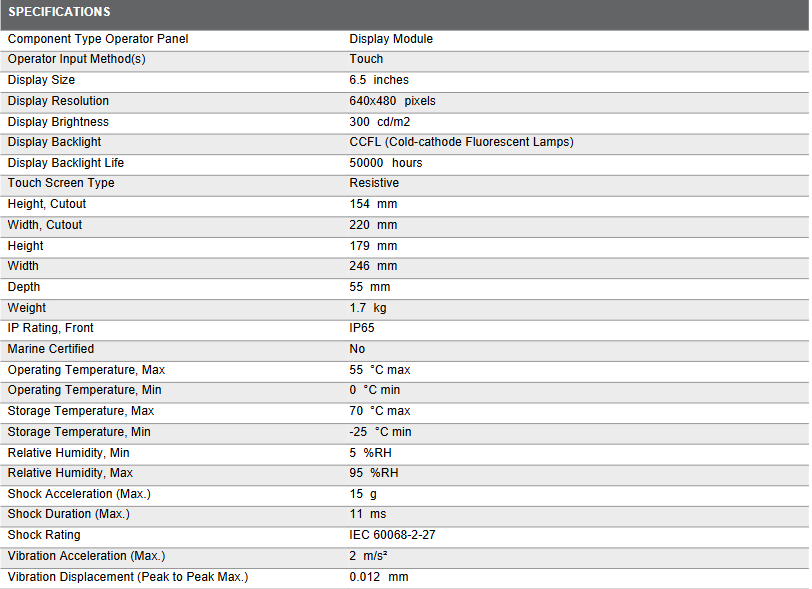

1. Display and operation unit

Category specific parameters

Display screen 6.5-inch TFT color screen, resolution 640 × 480 pixels, brightness 300 cd/m ², clear color display, suitable for workshop strong light environment

Backlight system cold cathode fluorescent lamp (CCFL) with an average lifespan of 50000 hours, meeting the long-term continuous industrial operation requirements

Touch function resistive touch screen, supporting precise single point touch operation, resistant to oil stains and wear, suitable for frequent use in industrial sites

The operation mode only involves touch input (without physical buttons), and the interface design is simple, reducing the risk of mechanical failure

2. Physical dimensions and installation

Hole size: width 220 mm x height 154 mm (standard hole for control cabinet, convenient for integrated installation);

Product dimensions: width 246 mm x height 179 mm x depth 55 mm, compact size, saving internal space of the control cabinet;

Weight: 1.7 kg, lightweight design, reduces installation load requirements;

Protection level: IP65 on the front (dustproof, splash proof, can be directly exposed to damp/dusty environments in the workshop), and the back needs to be installed inside the control cabinet (no clear protection level label, default to avoid direct contact with pollutants).

3. Environmental adaptability

Specific indicators of environmental parameters

Working temperature: 0 ℃~55 ℃ (covering most industrial workshops at room temperature to avoid extreme high/low temperatures)

Storage temperature -25 ℃~70 ℃ (meets the temperature and humidity requirements for logistics transportation and warehouse storage)

Relative humidity 5%~95% RH (non condensing, to avoid circuit short circuits or component aging caused by humidity)

Maximum acceleration of 15 g, duration of 11 ms, in compliance with IEC 60068-2-27 standard, resistant to transportation/installation impact

Anti vibration performance: maximum acceleration of 2 m/s ², peak displacement of 0.012 mm, maximum operating frequency of 500 Hz, in compliance with IEC 60068-2-6 standard, suitable for workshop equipment vibration environment

Ship certification is not available (not applicable to ship automation scenarios)

Performance and functional characteristics

1. Core performance parameters

Processor and Storage: Equipped with a high-performance processor and 512 MB of memory, it has fast response speed and supports complex interface rendering and multitasking;

Operating System: Pre installed Windows CE 6.0 system, high stability, compatible with industrial grade applications, supports third-party software integration;

Multi language support: Built in full Unicode fonts, a single runtime application can support multiple language switching (such as Chinese, English, German), suitable for cross-border factories or multilingual operation scenarios.

2. Key functions

(1) Data Management and Document Support

Formula management: supports the creation, storage, and retrieval of equipment process formulas, suitable for the production of multi specification products (such as switching processing parameters for parts of different sizes);

Data tracking: Record process data (such as production counts and equipment operating hours) in. csv format files for subsequent analysis and report generation;

PDF viewing: Equipped with a built-in PDF reader, it can load equipment manuals, operation guides, and other documents, providing context sensitive operator support (such as quick access to troubleshooting steps in case of malfunctions).

(2) Network and Communication

Built in interface:

Serial communication: 1 RS-232 port, compatible with traditional industrial equipment such as old PLCs and instruments;

Ethernet: 1 Ethernet port, supporting industrial Ethernet communication, enabling high-speed data exchange with the controller;

Expansion interface: Built in USB port (for external device connection, such as mouse and USB data transfer) and SD card slot (for extended storage, saving recipes or log files);

Remote monitoring: supports real-time monitoring of terminal status (such as device operation data and alarm information) through a web browser, without the need for on-site operation, improving operation and maintenance efficiency.

(3) Modular design

Adopting a modular architecture of "logic module+display module+communication module", it can expand functions as needed (such as adding communication protocol support, upgrading logical computing capabilities), reduce later transformation costs, and facilitate fault diagnosis and module replacement.

Compliance certification and reference documents

1. Certification standards

Basic certification: Complies with the IEC series standards (impact resistance IEC 60068-2-27, vibration resistance IEC 60068-2-6) to ensure reliability in industrial environments;

Explosion proof/Special Certification: No hazardous environment certification such as IECEx (not applicable to explosion-proof areas such as chemical, oil and gas);

Regional Compliance: Provide a Supplier Declaration of Conformity to meet market access requirements in different regions.

2. Reference materials

Users can obtain the following documents through Allen Bradley's official channels, which support installation and operation:

Installation Guide: Detailed instructions on equipment drilling, wiring, and fixing steps;

User Manual: covering interface configuration, function configuration, troubleshooting, and other operations;

Manufacturer's data manual and product selection catalog: Provide complete technical parameters for comparison with products in the same series to assist in selection.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA