Siemens 6ES7511-1AK02-0AB0 SIMATIC S7-1500 CPU 1511-1 PN Central Processing Unit

Siemens 6ES7511-1AK02-0AB0 SIMATIC S7-1500 CPU 1511-1 PN Central Processing Unit

Product positioning and core identification

6ES7511-1AK02-0AB0 is a CPU 1511-1 PN central processing unit under the Siemens SIMATIC S7-1500 series, designed specifically for small and medium-sized industrial automation scenarios. Its core function is to integrate logic control, motion control, process control, and industrial communication capabilities, adapt to discrete manufacturing (such as machine tools and assembly lines), process industry (such as chemical and water treatment), and hybrid control scenarios, support distributed I/O expansion, and balance performance and flexibility.

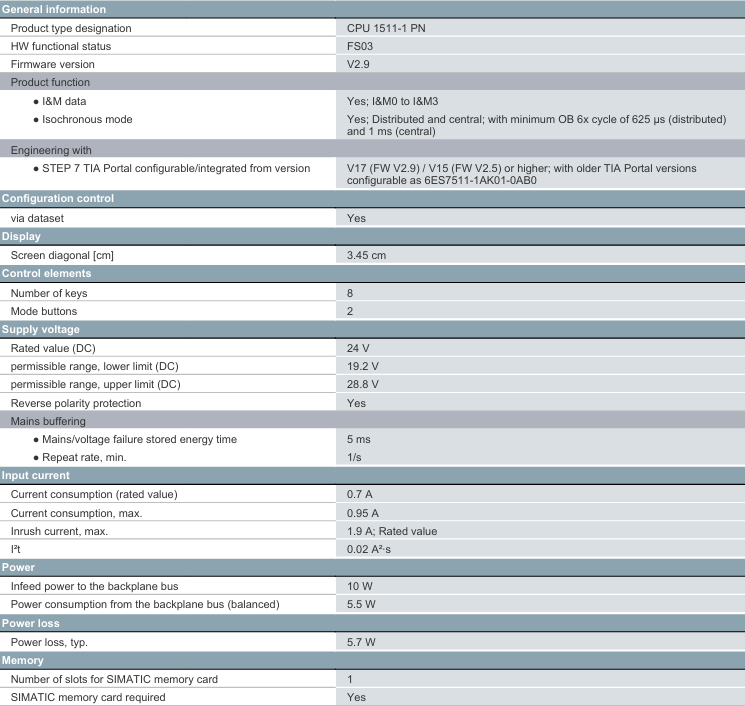

Core hardware specifications

1. Processor and Storage

Category specific parameters

Typical processing speeds for bit operations are 60 ns, word operations are 72 ns, fixed-point arithmetic is 96 ns, and floating-point arithmetic is 384 ns, meeting the real-time control requirements of small and medium-sized systems

Working memory - Program memory: 150 KB (for storing user programs and system configurations)

-Data memory: 1 MB (cache process data, variables, and status information)

Loading memory supports 1 SIMATIC memory card (required, separately purchased), with a maximum capacity of 32 GB, used for program storage, data logging, and firmware upgrades

Keep Memory - Standard Keep Area: 128 KB (including timers, counters, flag bits, actually available 88 KB)

-Extended hold area: 1 MB (requires a 60W 24/48/60 V DC HF power supply)

2. Power supply and power consumption

Power supply voltage: 24 V DC (industrial standard DC power supply), allowable range 19.2~28.8 V DC;

Current parameters: rated current 0.7 A, maximum current 0.95 A, maximum impulse current 1.9 A (I ² t=0.02 A ² · s);

Power protection: supports reverse polarity protection to prevent equipment damage caused by wiring errors;

Power consumption: The input power of the backplane bus is 10 W, the balanced power consumption is 5.5 W, the typical power consumption is 5.7 W, and the low-power design is suitable for energy-saving systems.

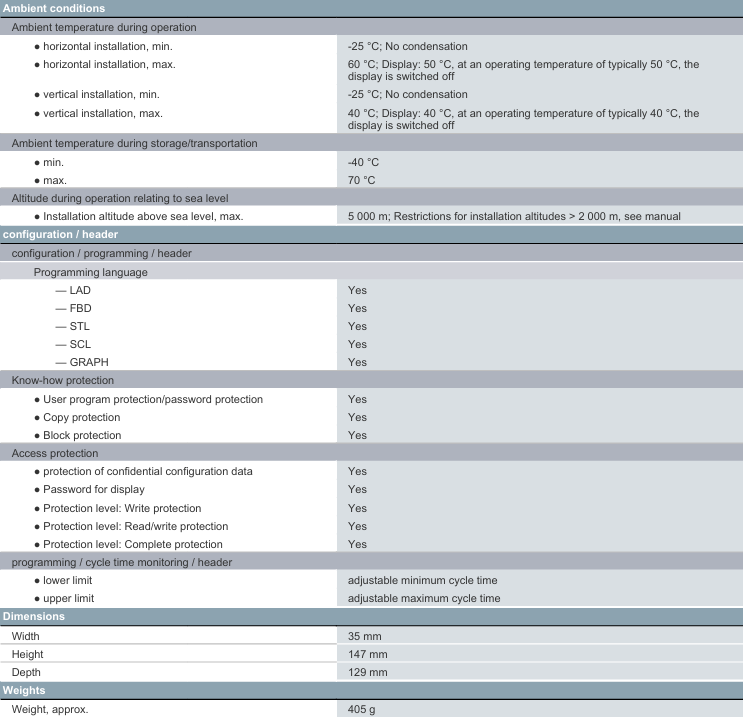

3. Physical dimensions and installation

Dimensions: Width 35 mm x Height 147 mm x Depth 129 mm (Compact design, compatible with S7-1500 standard rack);

Installation method: DIN rail installation (compliant with EN 50022 standard), single rack supports up to 32 modules (CPU+31 expansion modules);

Weight: Approximately 405 g, lightweight design reduces the load-bearing pressure of the rack.

4. Display and operation

Display screen: A small 3.45 cm (1.36 inch) display panel used for status indication and basic operations;

Operation buttons: 8 function keys+2 mode buttons (RUN/STOP), supporting manual switching of operating modes and parameter settings;

Indicator lights: RUN/STOP, ERROR, MAINT, STOP ACTION, and LINK TX/RX status lights, providing visual feedback on device operation and communication status.

Communication interface and protocol

1. Core communication interface

Number and specifications of interface types

PROFINET interface 1 integrated PROFINET IRT interface (X1), including 2 RJ45 ports, built-in switch, supports 100 Mbps speed, with LINK TX/RX indicator light

Extended communication supports the expansion of interfaces such as PROFIBUS and Ethernet through CM/CP modules, and can accommodate up to 4 CM/CP modules

2. Support protocols and functions

(1) PROFINET Core Features

IO Controller/Device: Supports dual roles of PROFINET IO Controller and IO Device, connecting up to 128 IO Devices (of which 64 support IRT), and a total of 256 distributed I/O devices (including AS-i and PROFIBUS);

Real time performance: The minimum update time in IRT mode is 250 μ s (in conjunction with isochronous mode OB 6x, with a minimum cycle of 625 μ s), and the minimum update time in RT mode is 250 μ s;

Redundancy and Security: Supports Media Redundancy Protocol (MRP, compliant with IEC 62439-2), with a typical ring network switching time of 200ms; supports MRPD (requiring IRT), achieving interference free switching; Support PROFIenergy energy-saving protocol (requires user program configuration).

(2) Other industrial agreements

Industrial Ethernet protocols: TCP/IP, ISO on TCP (RFC1006), UDP (supports multicast, maximum data length 2 KB), DHCP, DNS, SNMP, DCP, LLDP;

SIMATIC proprietary protocols: S7 communication (client/server), S7 routing (up to 16 paths), PG/OP communication (supporting TLS V1.3 encryption);

Open protocol: OPC UA (requires "Small" operating license) MODBUS TCP;

Time synchronization: Supports NTP protocol and master-slave synchronization within AS, with a hardware clock backup time of 6 weeks (at 40 ℃ environment) and a maximum daily deviation of 10 seconds (typical 2 seconds).

3. Connection ability

Maximum number of connections: 96 (including integrated interfaces and extended CM/CP interfaces), with 10 reserved for ES/HMI/Web communication;

S7 Communication: Supports encrypted S7 communication, maximum user data length reference online help;

Web Server: Built in web server, supports HTTP/HTTPS access, customizable user pages, supports encrypted communication.

Control function and performance

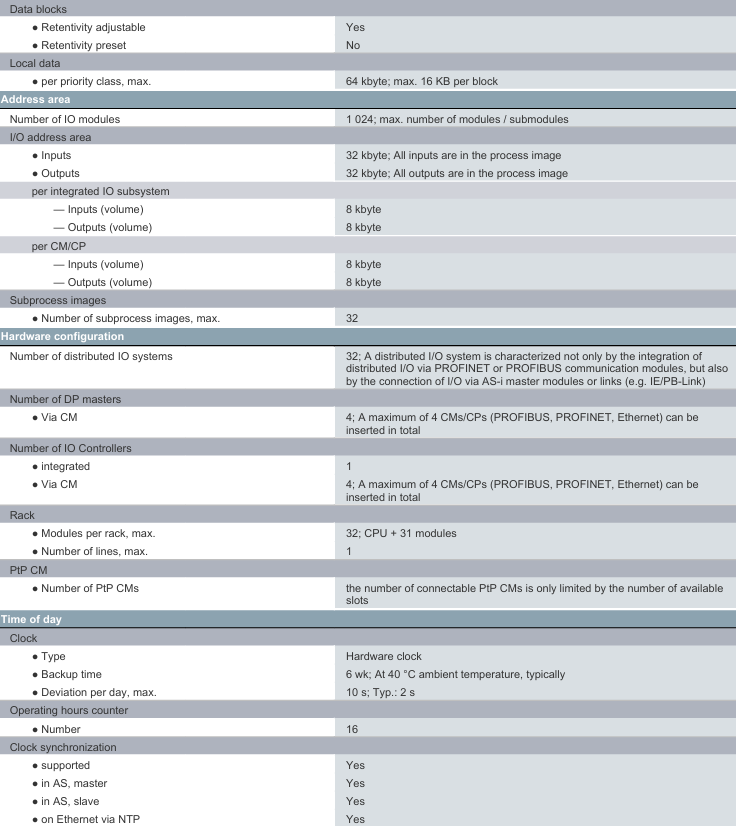

1. Program and task management

(1) Program capacity and block resources

Specific parameters of resource type

Up to 4000 data blocks (DB) (including UDT), address range 1~60999 (user available 1~59999), maximum 1 MB per DB (absolute addressing DB maximum 64 KB)

Function blocks (FB/FC) have a maximum of 65535 FB and FC respectively, with a maximum of 150 KB for a single FB/FC/OB

Organizational Block (OB) supports multiple types of OB: 100 free loop OB, 20 time alarm OB, 20 loop interrupt OB (minimum cycle 500 μ s), 50 process alarm OB, etc

(2) Task scheduling

Support priority task management (levels 0-15), with each priority class nested at a depth of 24 levels;

The isochronous mode supports both distributed and centralized modes, with a minimum OB 6x cycle of 625 μ s (distributed) and 1 ms (centralized), meeting high-precision synchronous control requirements.

2. Timers and counters

S7 timer/counter: 2048 each, supporting retention (configurable);

IEC timer/counter: unlimited quantity (limited only by memory), supports persistent configuration;

Clock memory: 8 clock memory bits (1 byte) used to generate periodic signals (such as 0.5 s, 1 s pulses).

3. Technical functions (motion, process control)

(1) Motion control

Resource support: Supports Motion Control technology objects, with a total of 800 resources allocated as follows:

Speed control axis: 40 resources/axis; Positioning axis: 80 resources/axis; Synchronization axis: 160 resources/axis;

External encoder: 80 resources per unit; Output cam: 20 resources/piece; Cam trajectory: 160 resources/piece; Probe: 40 resources/piece;

Number of axes: up to 5 positioning axes in a 4 ms motion control cycle, and up to 10 positioning axes in an 8 ms cycle.

(2) Process control

PID controller: supports PID_Compact (universal PID), PID_Step (valve specific), PID Test (temperature specific), all with integrated optimization function;

High speed counting: Supports high-speed counter function and is suitable for pulse signal acquisition (such as encoder signals).

4. Diagnosis and Debugging

Diagnostic buffer: up to 1000 records (including 500 power down hold), recording device faults, program errors, and other information;

Tracking function: up to 4 configurable traces, each with a maximum of 512 KB of data, used to record variable changes and program execution trajectories;

Online debugging: Supports Team Engineering (up to 5 engineering systems can be accessed online in parallel), up to 8 breakpoints, variable status monitoring and forcing (up to 200 peripheral I/O variables).

Environmental adaptability and certification

1. Environmental parameters

Specific indicators of environmental parameters

Working temperature - horizontal installation: -25 ℃~60 ℃ (the display screen automatically turns off when it reaches 50 ℃)

-Vertical installation: -25 ℃~40 ℃ (display screen automatically shuts off at 40 ℃)

Storage/transportation temperature -40 ℃~70 ℃ (non condensing)

Relative humidity 5%~95% RH (non condensing)

The maximum installation altitude is 5000 meters (when the altitude is>2000 meters, please refer to the manual for restrictions)

The anti vibration performance meets the IEC 60068-2-6 standard, with a maximum acceleration of 5 m/s ² at frequencies ranging from 10 to 500 Hz

The impact resistance performance meets the IEC 60068-2-27 standard, with a continuous duration of 11 ms at an acceleration of 15 g

2. Compliance certification

Safety certification: UL 508, CSA C22.2 No. 142, EN 61131-2;

Electromagnetic compatibility (EMC): EN 61000-6-2 (anti-interference in industrial environments), EN 61000-6-4 (emission in industrial environments);

Hazardous environment certification: Supports EX Zone 2/22 (requires corresponding module coordination);

Regional compliance: CE mark, in compliance with EU market access requirements.

Programming and Security

1. Programming software and language

Supported software: STEP 7 TIA Portal V15 (firmware V2.5) and above, V17 supports firmware V2.9; The old version of TIA Portal is compatible with configuration 6ES7511-1AK01-0AB0;

Programming language: Supports ladder diagrams (LAD), function block diagrams (FBD), statement tables (STL), structured text (SCL), and sequential function diagrams (GRAPH) to meet different programming habits.

2. Security protection

Program protection: supports user password protection, block protection, and copy protection (Know how protection) to prevent unauthorized modification and copying;

Data Security: Confidential configuration data protection, display password protection, support three-level access permissions (write protection, read/write protection, full protection);

Communication encryption: PG/OP communication, web servers, S7 communication support TLS V1.3 encryption, OPC UA supports multiple security policies (such as Basic256Sha256).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com