ABB ACS880-01-025A-3 frequency converter

Structure type, power range, typical application scenarios, core characteristics

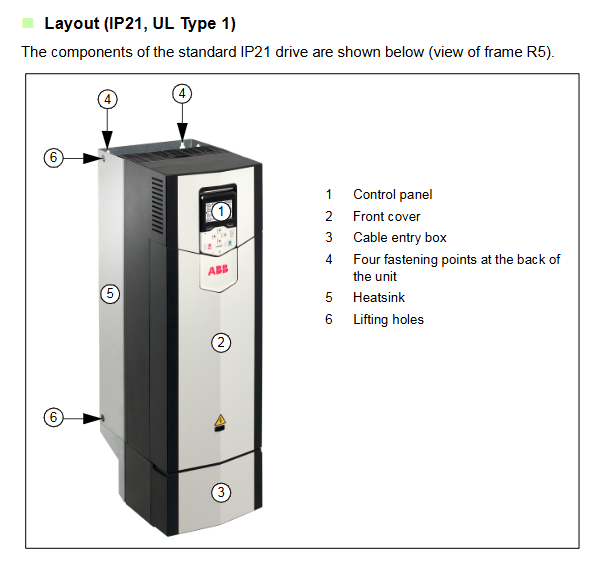

Wall mounted (Type 01) 0.55kW-75kW small and medium power single machine control (such as fans, water pumps, conveyor belts) with compact size, IP21 protection (preventing vertical dripping and solid foreign objects), natural cooling or forced air cooling, suitable for installation in control cabinets/dry environments

Cabinet style (04/06 type) 11kW-2800kW high-power or complex control (such as rolling mill, compressor, centrifuge) independent cabinet design, IP21/IP54 protection optional, built-in cooling system (air-cooled/water-cooled), integrated input circuit breaker, reactor and other accessories, supports multi machine linkage

Modular (02 type) 160kW-2800kW ultra high power scenarios (such as mine hoists, large fans) modular components (power modules, control units, auxiliary modules) that need to be matched with user made cabinets, support redundant design, and adapt to customized systems

ABB ACS880-01-025A-3 frequency converter

Product classification and structural design

The ACS880 series is divided into three categories based on installation method and power range, suitable for different industrial environment requirements:

Structure type, power range, typical application scenarios, core characteristics

Wall mounted (Type 01) 0.55kW-75kW small and medium power single machine control (such as fans, water pumps, conveyor belts) with compact size, IP21 protection (preventing vertical dripping and solid foreign objects), natural cooling or forced air cooling, suitable for installation in control cabinets/dry environments

Cabinet style (04/06 type) 11kW-2800kW high-power or complex control (such as rolling mill, compressor, centrifuge) independent cabinet design, IP21/IP54 protection optional, built-in cooling system (air-cooled/water-cooled), integrated input circuit breaker, reactor and other accessories, supports multi machine linkage

Modular (02 type) 160kW-2800kW ultra high power scenarios (such as mine hoists, large fans) modular components (power modules, control units, auxiliary modules) that need to be matched with user made cabinets, support redundant design, and adapt to customized systems

Electrical performance and speed regulation capability

The manual specifies the series of general electrical parameters, and the differences between different models are distinguished by the "model suffix" (such as voltage level, power code):

Input voltage range:

Low voltage series: 200-240V AC (single-phase/three-phase), 380-480V AC (three-phase), 500-690V AC (three-phase), all supporting ± 10% voltage fluctuation;

Frequency adaptation: 50/60Hz (± 5% fluctuation), compatible with global grid frequencies.

Output performance:

Output frequency: 0-500Hz (standard), 0-1000Hz (high frequency optional), supporting high-speed motor speed regulation;

Speed control accuracy: open-loop V/F control ± 0.5% rated speed, closed-loop vector control ± 0.1% rated speed;

Starting torque: 150% rated torque @ 0Hz under vector control (suitable for heavy-duty starting, such as crushers and extruders).

Control mode:

Basic mode: V/F control (square torque/constant torque curve optional, suitable for loads such as fans and pumps);

Advanced modes: sensorless vector control (no encoder required, suitable for scenarios without position feedback), closed-loop vector control (with encoder, high-precision speed regulation), torque control (constant torque output, such as curling equipment);

Special functions: synchronous control (multi motor speed/torque synchronization), process PID control (built-in PID regulator, directly related to process parameters such as pressure and flow), energy-saving mode (automatic optimization of voltage frequency ratio, reducing no-load losses).

Safety and protection functions

The manual emphasizes the safety design of the series, which complies with international safety standards such as IEC 61800-5-1. The core protection functions include:

Motor protection: overcurrent, overload (inverse time characteristic), locked rotor, phase loss, over temperature (supporting motor PTC thermistor connection), insulation monitoring;

Inverter protection: DC bus overvoltage/undervoltage, IGBT module overheating, input phase loss, output short circuit, ground fault (optional residual current detection), lightning surge protection;

System safety: Safe torque shutdown (STO, SIL2 certification, cutting off motor torque output in emergency situations), safe stop (SS1/SS2, compliant with EN ISO 13850), adapted to industrial safety circuit design.

Communication and integration capabilities

The ACS880 series supports multi protocol communication, making it easy to connect to PLC, DCS, or upper computer systems. The manual provides detailed instructions on the configuration methods for each protocol

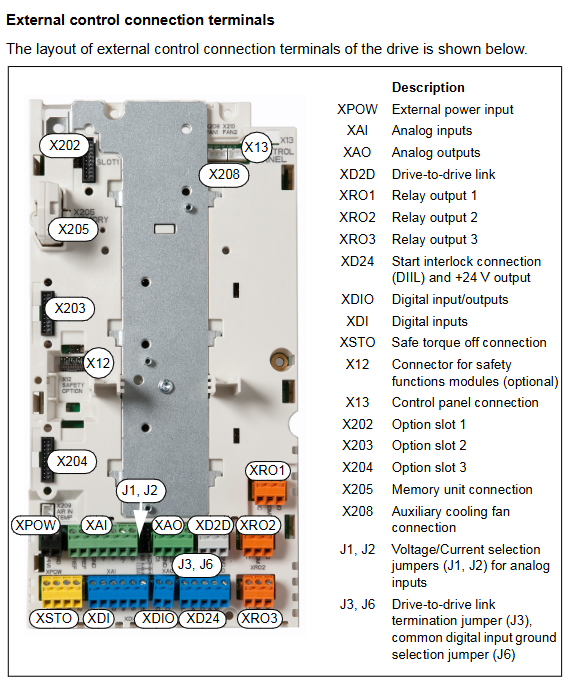

Standard communication: RS485 interface (supporting Modbus RTU protocol), used for local small-scale communication;

Optional modules: Profinet, EtherNet/IP, DeviceNet, CANopen, Profibus DP and other industrial Ethernet modules to achieve high-speed remote monitoring and multi device linkage;

ABB exclusive protocol: Supports ABB DriveBus and can quickly network with ABB PLC (such as AC500) or other ACS880 frequency converters, simplifying synchronous control configuration.

Manual Key Operation Guide (Installation, Debugging, and Maintenance)

1. Installation and wiring specifications

The manual specifies the prerequisites for safe installation (such as power-off operation, electrostatic protection) and core steps:

Installation environment requirements: working temperature -25~40 ℃ (some models can be extended to -40~50 ℃), relative humidity 5% -95% (no condensation), altitude ≤ 1000m (reduced capacity is required for use at high altitudes), away from dust, corrosive gases, and strong electromagnetic interference sources;

Wiring points:

The main circuit (input L1/L2/L3, output U/V/W) needs to match the cross-sectional area of the wires (according to the rated current), and install input circuit breakers and reactors (to suppress harmonics, optional);

Shielded wires are required for control circuits (analog I/O, digital I/O, encoder interfaces), with the shielding layer grounded at one end to avoid parallel laying with the main circuit cable (reducing interference);

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands