ABB Symphony Plus S+Control BRC410 Controller

ABB Symphony Plus S+Control BRC410 Controller

Product core positioning and brand background

BRC410 is the core controller module in ABB's Symphony Plus distributed control system (DCS), positioned as an integrated solution of "high-performance control+multi device integration". It inherits the reliability and compatibility of ABB's classic Symphony series DCS, while integrating new generation hardware and communication technologies. Its core goal is to provide high-precision process control, flexible equipment integration, and seamless system upgrade capabilities for key industries such as power and water, ensuring the continuity, efficiency, and scalability of industrial production.

The Symphony series DCS has a history of over 30 years of application, with over 6000 installations worldwide, of which 4000+are used in the fields of power and water. BRC410, as the new generation controller of this series, continues ABB's core policy of "Desarrollo sin caer en desuso", ensuring compatibility with the hardware architecture and software functions of previous products such as BRC400, HPG800, Network 90, INFI 90, and protecting users' existing asset investments.

Core functions and technological advantages

(1) High performance process control capability

BRC410 takes "high precision, high response, and high flexibility" as its control core, meeting the requirements of continuous, sequential, batch, and advanced control. The key characteristics are as follows:

Technical parameters, specific specifications, functional advantages

Hardware foundation: 32-bit Freescale Coldfire processor with a main frequency of 160 MHz, fast computing speed, and a performance improvement of 10 times compared to previous generation controllers. It can quickly handle complex control algorithms

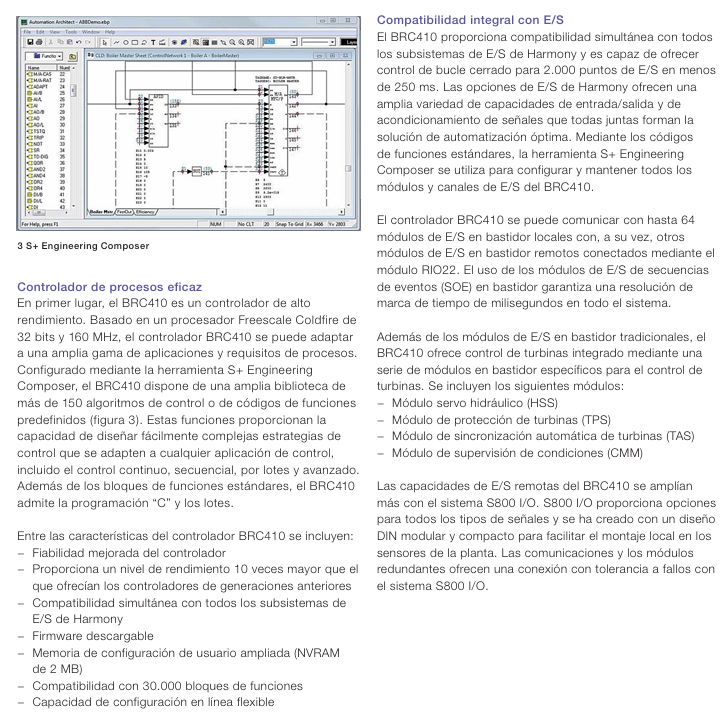

The control algorithm library has 150+predefined function blocks (such as PID, logic control, batch control blocks) built-in, supporting C language programming and batch control without the need for zero development. It can quickly build complex control strategies (such as turbine control in the power industry and water treatment process control in the water industry)

The control scale supports 30000 functional blocks and can achieve closed-loop control of 2000 I/O points (cycle period<250 ms) to meet the centralized control requirements of multiple devices in medium and large industrial scenarios (such as large thermal power plants and urban sewage treatment plants)

Reliability design supports redundant configuration (forming a redundant pair with BRC400/HPG800), firmware is downloadable, 2 MB NVRAM user configured memory redundancy design reduces the risk of single point of failure, NVRAM ensures that configuration data is not lost after power failure, firmware online updates do not interrupt operation

(2) Fully compatible I/O control capability

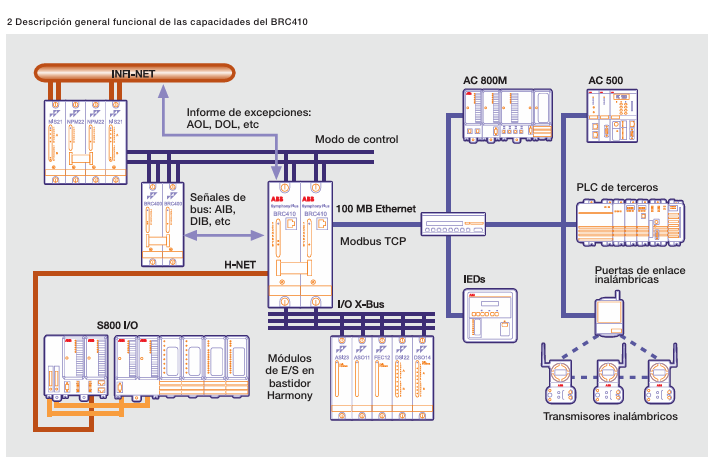

BRC410 achieves seamless integration with ABB's full range of I/O subsystems, covering local and remote I/O requirements, while providing industry-specific control modules, including:

I/O compatibility and expansion

Local I/O: Up to 64 Harmony rack mounted I/O modules can be connected, supporting signal types such as digital (DI/DO), analog (AI/AO), and sequence of events (SOE). The SOE module has a timestamp resolution of milliseconds, meeting the high-precision time recording requirements for fault tracing;

Remote I/O: Expand remote rack mounted I/O through RIO22 module, and be compatible with S800 I/O system (DIN rail modular design, compact size, can be installed near on-site sensors), reducing signal transmission loss and wiring costs;

Specialized control module: For the steam turbine control scenario in the power industry, customized rack mounted modules are provided, including hydraulic servo module (HSS), steam turbine protection module (TPS), automatic synchronization module (TAS), and status monitoring module (CMM), achieving the integration of "control+protection+monitoring".

I/O configuration tool

Through S+Engineering Composer software, all I/O modules and channels can be uniformly configured, supporting flexible online configuration adjustment. Signal type, range and other parameters can be modified without stopping the machine, adapting to dynamic changes in the production process.

(3) Multi device integration and communication capability

BRC410 breaks through the limitations of traditional controllers' "single control" and achieves real-time bidirectional integration of multiple protocols and devices through Harmony Gateway Software (HGS). The core communication characteristics are as follows:

Specific specifications and application value of communication parameters

Core interface 100 MB Ethernet port, supports Modbus TCP protocol instead of traditional RS232/RS485 serial port, achieves high-speed data transmission, compatible with industrial standard Ethernet devices (such as switches, fiber routers)

The integration scale supports up to 4000 Modbus points for bidirectional communication, and can be used as a Modbus TCP client, server, or both to flexibly interface with third-party devices

-As a 'client': collecting data from intelligent electronic devices (IEDs, such as meters and sensors);

-As a 'server': pushing control data to third-party PLCs (such as AC 800M, AC 500) or SCADA systems;

-Bidirectional mode: enables real-time data exchange and control command issuance with wireless HART transmitters

Redundancy and Reliability Redundancy supports communication link fault tolerance under configuration, and is paired with industrial grade Ethernet devices (such as fiber optic switches) to achieve long-distance (fiber optic link) and high reliability communication. It is suitable for cross plant and strong interference scenarios (such as power plant boiler areas and water pump stations), ensuring uninterrupted communication

Seamless system upgrade and compatibility

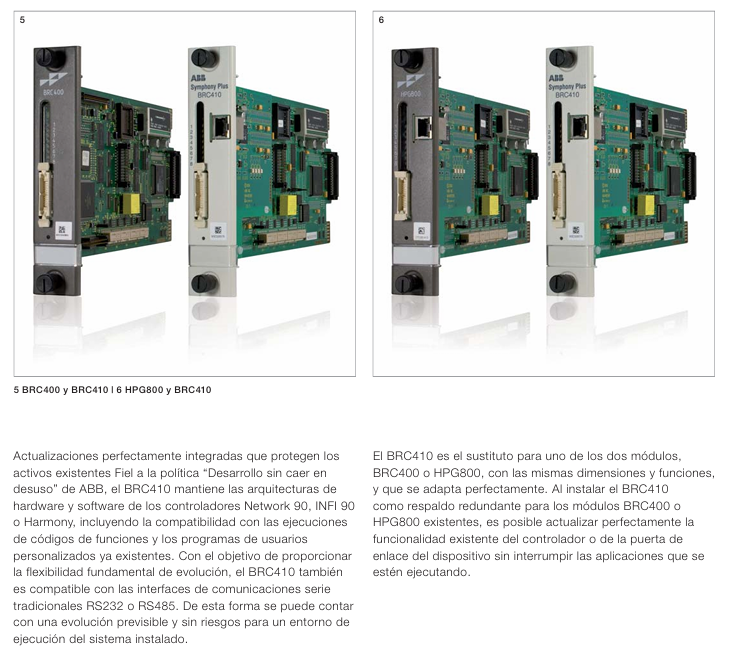

BRC410 is the core carrier of ABB's "development without elimination" policy, and its compatibility and upgrade capabilities are designed to fully protect users' existing investments, specifically reflected in:

Hardware and functional compatibility

Consistent in size and functional interoperability with previous generation controllers (BRC400, HPG800), one module can be directly replaced as a redundant backup without the need to modify cabinet layout or wiring;

Compatible with user-defined programs and functional block execution logic of old systems such as Network 90 and INFI 90, it can be migrated to BRC410 without rewriting code.

Online upgrade capability

When BRC410 is used as a redundant backup module for BRC400 or HPG800, it can gradually upgrade controller functions (such as upgrading from "basic control" to "Modbus TCP integration") or gateway capabilities without interrupting existing production applications, achieving "zero downtime upgrade";

Supports the coexistence of traditional RS232/RS485 serial port interfaces and new generation Ethernet interfaces. Users can transition to high-speed Ethernet communication in stages according to their needs, avoiding one-time system replacement costs.

Typical application scenarios

BRC410, with its characteristics of "high reliability, strong compatibility, and multi scenario adaptation", is core applied in the following fields:

Power industry: Unit control of thermal power plants and hydropower plants (such as boiler water level control, turbine speed regulation), control of auxiliary systems (pumps, fans), and exchange of power grid dispatch data;

Water industry: urban waterworks (dosing, filtration process control), sewage treatment plants (aeration, sedimentation process control), supporting data integration with remote pumping station's IED equipment;

Other key industries: continuous production process control in chemical, metallurgical and other fields, compatible with third-party equipment (such as flow meters, valve positioners), achieving full process automation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA