Watlow CLS200 series controller

Space and efficiency optimization: A single device supports PID control for up to 16 heating/cooling circuits, significantly reducing the panel space occupied by a single circuit, while reducing the number of installed components, lowering the probability of failure, and shortening installation time;

Simplified operation: It has menu guided operation+full-text display, supports storage and calling of 8 job programs, can quickly switch production processes, and the "Auto tune" function reduces the professional threshold for parameter settings;

Strong compatibility: Supports thermocouples RTD、 Multiple sensor inputs such as linear DC voltage/current reduce user learning costs and spare parts inventory; Built in EIA/TIA-232/485 serial communication interface, seamlessly integrated with PLC and upper computer software (such as WATVIEW).

This series of controllers is approved by UL ®、 C-UL ® Certified to comply with the EU EMC Directive and bear the CE mark, suitable for multi loop control scenarios in the field of industrial automation (such as plastic extrusion, mass production, etc.).

Watlow CLS200 series controller

Core positioning and overall advantages of the product

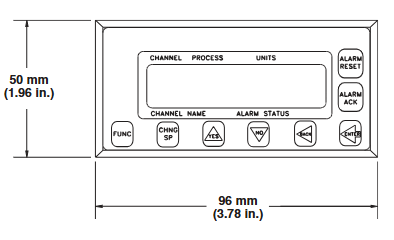

The CLS200 series controller is designed with a compact 1/8 DIN package, which enables precise control of multiple circuits in a limited space. Its core advantages are concentrated in three dimensions: "efficiency, flexibility, and ease of operation"

Space and efficiency optimization: A single device supports PID control for up to 16 heating/cooling circuits, significantly reducing the panel space occupied by a single circuit, while reducing the number of installed components, lowering the probability of failure, and shortening installation time;

Simplified operation: It has menu guided operation+full-text display, supports storage and calling of 8 job programs, can quickly switch production processes, and the "Auto tune" function reduces the professional threshold for parameter settings;

Strong compatibility: Supports thermocouples RTD、 Multiple sensor inputs such as linear DC voltage/current reduce user learning costs and spare parts inventory; Built in EIA/TIA-232/485 serial communication interface, seamlessly integrated with PLC and upper computer software (such as WATVIEW).

This series of controllers is approved by UL ®、 C-UL ® Certified to comply with the EU EMC Directive and bear the CE mark, suitable for multi loop control scenarios in the field of industrial automation (such as plastic extrusion, mass production, etc.).

Differences in Model Classification and Core Functions

The CLS200 series is divided into core models according to the "number of circuits", and there are clear differences in input types and channel quantities among different models. At the same time, the "firmware options" can be used to expand functions to meet different application needs:

1. Classification of basic models (by number of circuits/channels)

Model Channel Quantity Input Type Core Adaptation Scenario

CLS204 4 differential input small multi loop control (such as 4-channel temperature control)

CLS208 8 differential input medium-sized multi loop control, supporting RTD input

CLS216 16 single ended input large multi loop centralized control

2. Firmware function options (select as needed)

Different firmware versions determine the core algorithms and functional range of the controller, covering requirements from basic temperature control to complex process control

Standard firmware: Basic closed-loop PID control, automatic tuning, fault sensor detection, alarm function, job storage;

Extruder specific firmware: Based on standard functions, optimize PID control logic for plastic extrusion process;

Ramp and Soak firmware: Added "ramp heating+constant temperature maintenance" function and process variable retransmission (requires SDAC module), supports complex batch processing;

Enhanced firmware: includes standard features, with additional support for cascade control, proportional control, differential control, and remote simulation set points. Each channel can flexibly configure control algorithms (note: cascade control/remote set points require 2 controller channels).

Key technical parameters

1. Human computer interaction and configuration

Display and operation: 32 character vacuum fluorescent display screen, 8-key keyboard (used for menu access, password verification, parameter settings, channel switching);

Configuration method: Controller parameters can be loaded through standard serial ports, supporting single channel/multi-channel display switching.

2. Input performance (sensors and signals)

(1) Input type and precision

Supporting multiple sensor inputs, the measurement range and accuracy of different types are shown in the table below:

Input type, specific specifications, accuracy (@ 25 ℃ environment)

Thermocouples support B/E/J/K/R/S/T types, including cold end compensation and reverse/short circuit detection; Type B has a range of 66-1760 ℃, Type K has a range of 268-1371 ℃ ± 1.0~4.0 ℃ (depending on the type, Type B has the lowest accuracy)

RTD is only supported by CLS204/CLS208, with 2/3 wire platinum resistance (100 Ω @ 0 ℃), divided into 2 ranges:

- RTD1:-100-275℃

- RTD2:-120-840℃ RTD1:±1.1℃; RTD2:±1.6℃

Linear signal supports 0-10mA/4-20mA DC current, 0-100mV/0-5V/0-10V/0-12V DC voltage (requires external scaling resistor)-

Pulse signal TTL level square wave, maximum frequency 2kHz-

(2) Input sampling and anti-interference

Sampling rate: CLS204 (6 times/second, update time 0.167 seconds), CLS208 (3 times/second, 0.333 seconds), CLS216 (1.5 times/second, 0.667 seconds);

Anti interference capability: noise suppression ratio of 120dB at a frequency of 60Hz, temperature coefficient of 40ppm/℃;

Measurement resolution:>14 bits, internal measurement accuracy 0.006%.

3. Output performance

Digital output: The number of outputs varies depending on the terminal board options - the 50 pin terminal board supports 34 digital outputs, while the 18 pin terminal board supports 10 control outputs; Each output can be configured as "switch time proportional control" or "distributed zero crossing (DZC) control", with a maximum single current of 60mA (5V DC), and the onboard power supply can provide 350mA (5V DC);

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA