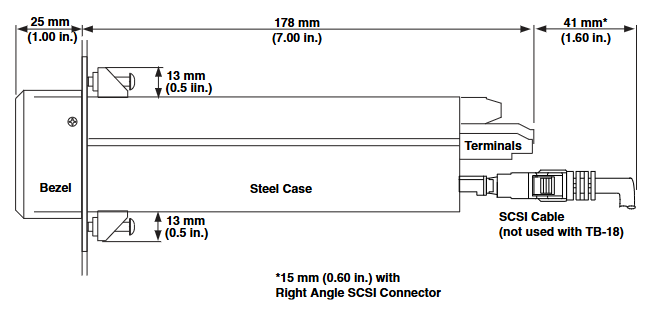

Watlow CLS200 series controller

Space and efficiency optimization: A single device supports PID control for up to 16 heating/cooling circuits, significantly reducing the panel space occupied by a single circuit, while reducing the number of installed components, lowering the probability of failure, and shortening installation time;

Simplified operation: It has menu guided operation+full-text display, supports storage and calling of 8 job programs, can quickly switch production processes, and the "Auto tune" function reduces the professional threshold for parameter settings;

Strong compatibility: Supports thermocouples RTD、 Multiple sensor inputs such as linear DC voltage/current reduce user learning costs and spare parts inventory; Built in EIA/TIA-232/485 serial communication interface, seamlessly integrated with PLC and upper computer software (such as WATVIEW).

This series of controllers is approved by UL ®、 C-UL ® Certified to comply with the EU EMC Directive and bear the CE mark, suitable for multi loop control scenarios in the field of industrial automation (such as plastic extrusion, mass production, etc.).

Alarm output: Each channel is independently configured with "process alarm" and "deviation alarm", supporting programmable dead zone, delay, and start suppression. The global alarm output can summarize the alarm status of all channels, and there is also a "watchdog output" to indicate that the controller is running normally.

4. Communication and Power Supply

Serial communication: Supports EIA/TIA-232 or EIA/TIA-485 (selectable via jumper), baud rates can be selected as 2400/9600/19200, protocol compatible with ANSI X3.28-1976 (D1, F1) and Allen Bradley PLC/2, Modbus ® RTU;

Power requirements: 15-24V DC (± 3V DC), maximum current 1A, current 300mA without load; optional 120/240V AC (50/60Hz) power adapter (output 15V) DC@1.2A , UL ® Class 2 certification).

5. Environmental adaptability

Working temperature: not clearly indicated (reference to general industrial equipment standards, estimated to be -10~55 ℃, subject to actual application);

Anti interference: Complies with industrial grade electromagnetic compatibility requirements (relying on the EMC testing standards corresponding to CE certification).

Optional accessories and software

1. Analog Conversion Module (DAC/SDC)

The CLS200 series has no onboard analog output and requires external modules to achieve analog signal conversion:

DAC module: converts the DZC output signals of 1-2 controllers into analog signals, and the output types can be configured on-site as 4-20mA DC, 0-5V DC, or 0-10V DC;

SDAC module (serial digital to analog converter): converts 1 controller output into high-precision analog voltage/current signals, suitable for scenarios such as process variable retransmission, open-loop control, motor speed control, etc., with CE, UL ®、 C-UL ® authentication.

2. Upper computer software (WATVIEW)

Optional Windows ®- Based HMI software, core functions include:

Simultaneously monitor/configure up to 32 CLS200 controllers;

Support parameter settings, custom recipe management, alarm monitoring, trend chart drawing, real-time data recording, and export log data to a spreadsheet;

Divided into "Run time" and "Developer" versions, the Developer version additionally supports custom interface design and has higher configuration efficiency than general HMI software.

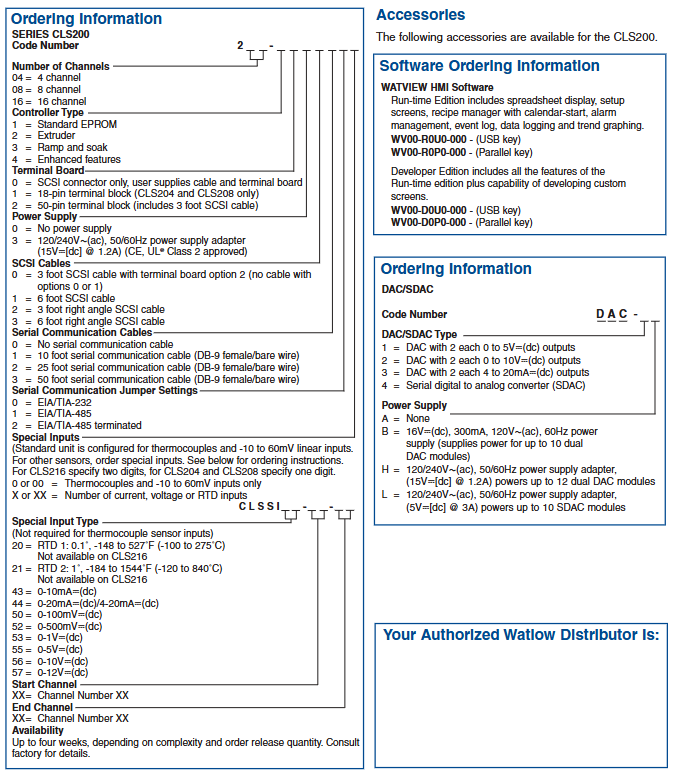

Order information and attachments

1. Core ordering code rules

The CLS200 series order requires clear parameters such as "number of channels, controller type, terminal board, power supply, communication accessories, and special inputs". The core code meanings are as follows:

Description of optional parameters for code snippets

Channel number 04=4 channels (CLS204), 08=8 channels (CLS208), 16=16 channels (CLS216)

Controller type 1=standard firmware, 2=extruder firmware, 3=ramp constant temperature firmware, 4=enhanced function firmware

Terminal board 0=SCSI interface only (user provided cable), 1=18 pin terminal board (CLS204/208 only), 2=50 pin terminal board (including 3-foot SCSI cable)

Power adapter 0=none, 3=120/240V AC to 15V DC (1.2A)

Serial communication configuration communication cable (0=none, 1=10 feet DB-9 cable, etc.), communication protocol (0=232, 1=485, 2=485 terminal matching)

Special input 0/00=thermocouple only+(-10~60mV), X/XX=custom current/voltage/RTD input (input type and channel range need to be specified)

2. Other attachments

Software keys: WATVIEW runtime version (WV00-R0U0-000=USB key, WV00-R0P0-000=parallel key), development version (WV00-D0U0-000=USB key, etc.);

DAC/SDC power supply: B=120V AC to 16V DC (300mA, for 10 DACs), H=120/240V AC to 15V DC (1.2A, for 12 DACs), L=120/240V AC to 5V DC (3A, for 10 SDACs).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA