Watlow Series CLS200 Controller

Watlow Series CLS200 Controller

The Watlow Series CLS200 is a compact loop control system that provides powerful control functions in a 1/8 DIN package. It features multi loop control, flexible input-output configuration, and multiple firmware options, making it suitable for a wide range of industrial control scenarios and complying with multiple international safety and electromagnetic compatibility standards.

Core product features and advantages

Multi loop PID control: Available in 4, 8, and 16 loop versions, it can simultaneously control heating and cooling circuits, saving panel space and reducing installation time for each loop, with fewer parts, and improving system reliability.

Intelligent control function: equipped with Auto tune function, parameter tuning can be quickly completed without the need for professional personnel, ensuring control accuracy; Supports storing and calling 8 job programs, making it easy to quickly switch production processes.

Flexible input support: Compatible with multiple sensor inputs, including thermocouples (Type B/E/J/K/R/S/T, etc.), RTDs (only supported for 4/8 loop models, divided into 2 ranges), linear DC voltage/current, and pulse signals, reducing learning costs and inventory pressure; Equipped with sensor fault detection, it can quickly troubleshoot issues such as reverse wiring, short circuits, and open circuits.

Intuitive operation and communication: equipped with a 32 character vacuum fluorescent display screen and an 8-key keyboard, menu guided operation, supporting single channel/multi-channel display switching; Built in EIA/TIA-232 and 485 serial communication interfaces, can be connected to computers or software to achieve configuration loading, data acquisition, and integration with other controllers. The baud rate can be selected from 2400, 9600, 19200, and supports ANSI X3.28-1976 (compatible with Allen Bradley PLC/2) and Modbus ® RTU protocol.

Alarm and output configuration: Each input channel has high/low process alarms and deviation alarms, and the alarm dead zone, delay, and startup suppression can be customized; Up to 34 digital outputs are provided (depending on the wiring method), which can be configured as switch time proportional control or distributed zero crossing control. The maximum sinking current for a single output is 60mA (5VDC), and the onboard power supply provides 350mA (5VDC) power supply; There are also global alarm outputs (triggered by any alarm) and watchdog outputs (indicating normal operation of the controller).

Firmware Options

According to application requirements, different firmware functions can be selected to meet basic to complex control scenarios:

Firmware type, core functions, applicable scenarios

Standard firmware closed-loop PID control, automatic tuning, alarm, job storage, sensor fault detection, basic temperature/process control, without the need for complex timing or special algorithms

The Ramp and Sok firmware includes standard functions, including temperature control programs and process variable retransmission. In batch production, heating is required according to specific temperature curves (such as material annealing and food processing)

The enhanced firmware includes standard features such as process variable retransmission, remote simulation set points, cascade control, ratio control, and differential control that require multi parameter linkage (such as temperature control in the main loop and heating power control in the secondary loop in cascade control) or remote setting of target values

Customized firmware development for unconventional industrial scenarios based on user specific needs, requiring dedicated control logic (contact Watlow representative)

Input/output and expansion module

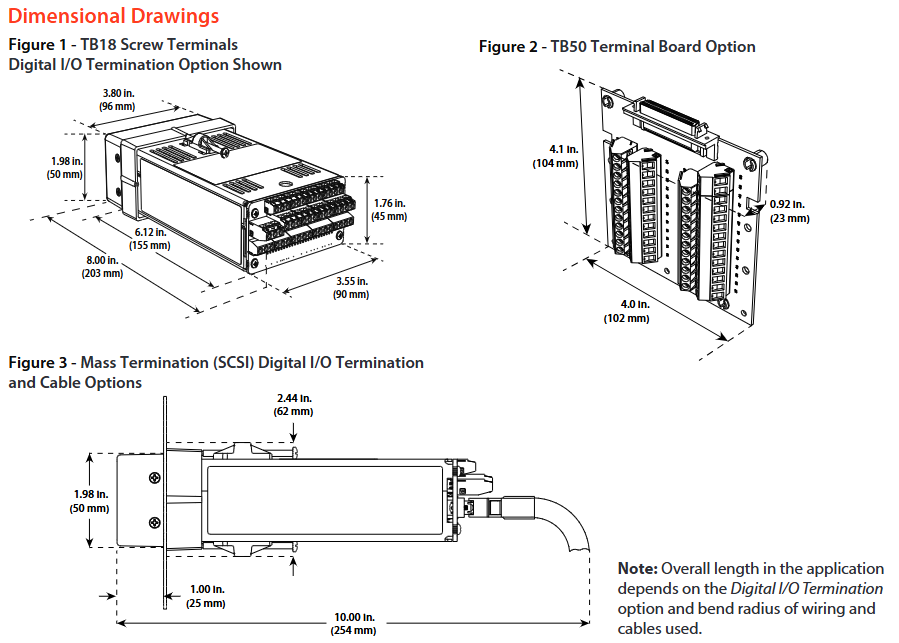

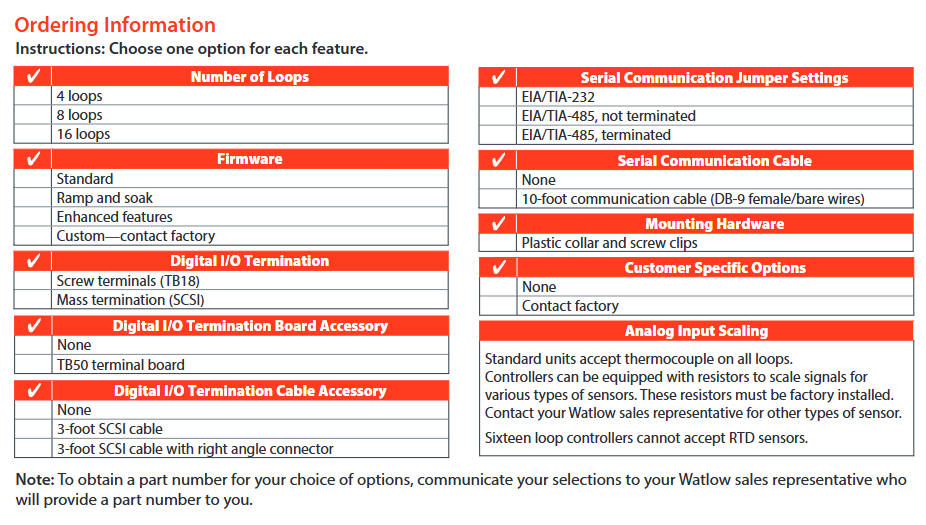

(1) Digital I/O wiring options

Different wiring methods correspond to different I/O quantities and interface types, adapting to different installation requirements:

Wiring type suitable for controller (number of circuits), I/O quantity, interface and accessories

Screw terminals (TB18) 4, 8, 15 outputs (10 can be used for control circuits), 3 inputs with back screw connections, no additional accessories required, suitable for small batch I/O connections

Large scale termination (SCSI) series with 34 outputs, 8 digital inputs+1 pulse input, 50 pin SCSI interface, requires SCSI cable and TB50 terminal board, suitable for multi I/O centralized connection

(2) Analog expansion module

Due to the lack of onboard analog output in the controller, analog signal conversion needs to be achieved through the following modules:

DAC module (digital to analog converter): converts 1-2 distributed zero crossing (DZC) outputs of the controller into analog signals, which can be configured on-site as 4-20mVDC, 0-5VDC, or 0-10VDC.

SDAC module (serial digital to analog converter): converts 1 controller output into high-precision voltage/current signals, supports process variable retransmission, open-loop control, motor/belt speed control, etc., in compliance with CE and UL ®、 C-UL ® Standard.

Key technical parameters

(1) Input performance

Analog input: 4/8 circuit model is differential input, 16 circuit model is single ended input; The maximum common mode voltage is 5V (4/8 circuits), the common mode rejection ratio (CMR) is>60dB (DC to 1kHz), 120dB (selected line frequency), the noise suppression is 120dB (60Hz), and the input overvoltage protection is ± 20V (relative to digital ground).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands