Emerson DeltaV SIS Logic Solver (SLS1508)

The world's first intelligent SIS logic solver: communicates with intelligent field devices through the HART protocol to diagnose faults in field instruments and final control components in advance (according to research, such faults account for more than 85% of SIS faults), avoiding false tripping, improving process availability, and reducing full lifecycle costs.

Emerson DeltaV SIS Logic Solver (SLS1508)

Core positioning and core advantages

The DeltaV SIS Logic Solver (SLS1508) is the core component of Emerson's Intelligent Safety Instrumented Systems (SIS), designed specifically for industrial process safety protection and meeting SIL 1-3 safety functional requirements. Its core advantages can be summarized into six key features:

The world's first intelligent SIS logic solver: communicates with intelligent field devices through the HART protocol to diagnose faults in field instruments and final control components in advance (according to research, such faults account for more than 85% of SIS faults), avoiding false tripping, improving process availability, and reducing full lifecycle costs.

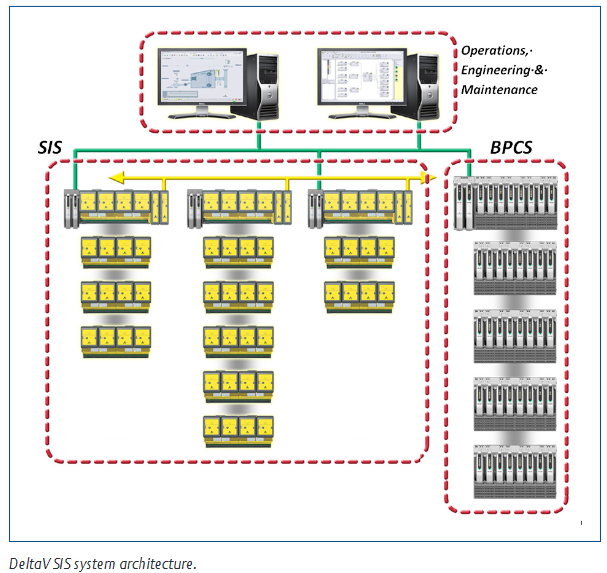

Integrated but independent with the control system: strictly follow safety standards, use dedicated hardware, software, and networks to implement safety functions, and eliminate the impact of common cause failures; Simultaneously achieve seamless integration of configuration, maintenance, and operating environment at the workstation level, balancing security and usability.

Easy to comply with IEC 61511 standard: provides strict user management functions, automatically verifies data for changes initiated by the human-machine interface (HMI) (such as trip limit modification), ensures accurate data writing into the target logic solver, and meets the strict requirements of the standard for change control.

Suitable for any scale of application: Whether it is an isolated wellhead or a large emergency shutdown (ESD)/fire and gas system, it can be flexibly expanded to cover SIL 1-3 safety functions; Each logic solver is equipped with dual CPUs and 16 I/O channels, allowing for system expansion without the need for additional processors. The scanning rate and memory usage are not affected by system size and remain stable.

SIL 3 certification and redundant architecture: The SLS1508 logic solver meets SIL 3 application requirements with a single unit, and the availability is higher when installed in pairs with redundancy; The redundant architecture includes dedicated redundant links, independent power supply, I/O redundant peer-to-peer links for real-time release, and dual machine shared input data to ensure reliable system operation.

Support for online addition of logic solvers: The system automatically detects new hardware every scanning cycle and can add devices to the online system in real-time without interrupting the process; Once the newly added device is recognized by DeltaV Resource Manager, it can be directly configured, greatly improving the flexibility of system expansion.

Core components and functional details of the product

(1) Core hardware components and system architecture

Component Name Function Description Key Features

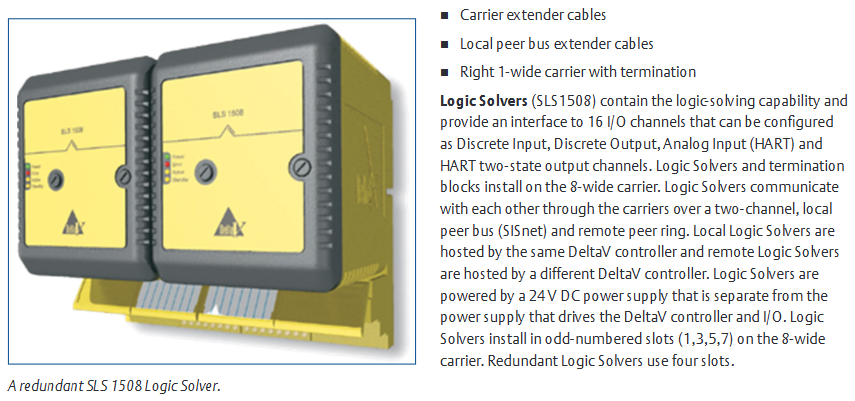

SLS1508 logic solver core safety logic operation unit, provides I/O interface with built-in dual CPU, 16 configurable I/O channels (discrete input/output, analog input (HART), HART dual state output), supports single SIL 3 application, and occupies 4 slots for redundant paired installation

The redundant terminal block connects the on-site wiring and logic solver to adapt to the SLS1508 redundant architecture, enabling redundancy without the need for additional control strategy configuration. The system automatically identifies redundant pairs

SISnet repeater extends the communication range of SISnet and realizes remote logic solver communication through fiber optic ring network. It is divided into two independent fiber optic rings, primary and backup. Please refer to the separate product manual for details

The carrier extension cable extends the local bus power and signal connection between 8-wide carriers, ensuring signal transmission between the controller, logic solver, and SISnet repeater

Local peer-to-peer bus extension cable extends SISnet communication between logic solvers on different carriers, supports interconnection of logic solvers across carriers, and builds a local SISnet network

The wide terminal carrier terminates the local peer-to-peer bus installed at the end of the carrier chain, providing SISnet bus terminal matching to ensure stable communication

The 8-width carrier carries logic solvers, SISnet repeaters, and other components. The logic solvers are installed in odd numbered slots (1/3/5/7) and support connecting multiple carriers through expansion cables

(2) Communication Network Design

Control Network: Implement communication between DeltaV network nodes, as detailed in the DeltaV Digital Automation System Installation Manual.

Local Bus: connects DeltaV controllers with logic solvers, SISnet repeaters, and transmits control and configuration signals.

Local Peer to Peer Bus (SISnet): a dual channel bus where logic solvers communicate with each other and with local SISnet repeaters through a carrier, and the same message is broadcasted on both channels; The two ends of the bus need to be terminated (the left end through a 2-wide power/controller carrier, and the right end through a 1-wide terminal carrier), and the repeater can be flexibly installed at any position on the bus.

Remote Peer Ring: SISnet repeaters hosted by different controllers communicate through fiber optic ring networks. Local repeaters aggregate global variable messages and transmit them along the ring network. Receiver repeaters broadcast and forward them on the local SISnet, while global messages are transmitted only once along the ring network. The primary and backup repeaters form independent fiber optic rings.

(3) Unique redundancy mechanism

Redundant operation mode: The redundant SLS1508 dual machine always runs in parallel, reading I/O inputs, executing safety logic, and driving outputs, without distinction between master and backup/master-slave; Only one (Active state, indicator light on) communicates with the workstation and SISnet, while the other (Standby state) only connects to SISnet.

Fault handling: When a single machine detects a fault, it automatically enters a failure state, and all output channels are powered off, but it does not affect the operation of another machine (continuing to read and write I/O, executing logic), and redundant switching is completely undisturbed; In safe areas, faulty modules can be replaced with electricity, while in hazardous areas, specific installation procedures must be followed.

Integrity alarm: Real time monitoring of redundant pair status, triggering alarm scenarios including: hardware failure of logic solver, communication failure between logic solver and SISnet, communication failure between redundant pairs, communication failure between logic solver and DeltaV controller, and removal of logic solver from carrier; Alarm information and device status can be viewed in the diagnostic browser.

Automatic verification testing: Redundancy can be configured for automatic verification testing. After setting the testing interval, the system will automatically execute and issue a warning to the operator before testing to ensure the effectiveness of safety functions.

(4) Sequence of Events (SOE) function

Basic function: Automatically generate events when executing function blocks during the module scanning cycle, with a timestamp resolution of<1ms, and record them in the event log in the order of occurrence; Standard functional blocks (input block, voting block, cause and effect block, etc.) can automatically generate events (such as I/O faults, trip limit triggering, first output signal) without special configuration, and record the simulated values and triggering conditions during tripping.

First out positioning: When the factory emergency stops, the "first out trip" signal in the event log can be filtered to quickly locate the first input that triggers the trip, simplifying fault diagnosis.

High resolution extension: If higher temporal resolution (0.25ms) is required, the channel can be simultaneously connected to SLS1508 and DeltaV discrete input SOE cards.

Hardware specifications and I/O channel parameters

(1) General Environment and Physical Specifications

1. SLS1508 Universal Environment Specification

Category parameter details

Working temperature -40~70 ° C (-40~158 ° F), long-term high-temperature operation shortens lifespan

Storage temperature -40~85 ° C (-40~185 ° F)

Relative humidity 5%~95% (no condensation)

Pollutant level ISA-S71.04-1985 G3 level (with conformal coating)

Protection level IP20

Hazardous Area Certification: European EMC Directive (EN61326-1, Criterion A), NAMUR NE21 EMC Requirements, Low Voltage Directive (IEC 61010-1), FM Class I Div 2 (Groups A-D, T4, No Arc) ATEX 3 G EEx IIC-nA T4(EN50021:1999)、CSA 1010

Anti impact 10g half sine wave (continuous for 11ms)

Vibration 5-16Hz (1mm peak to peak), 16-150Hz (0.5g)

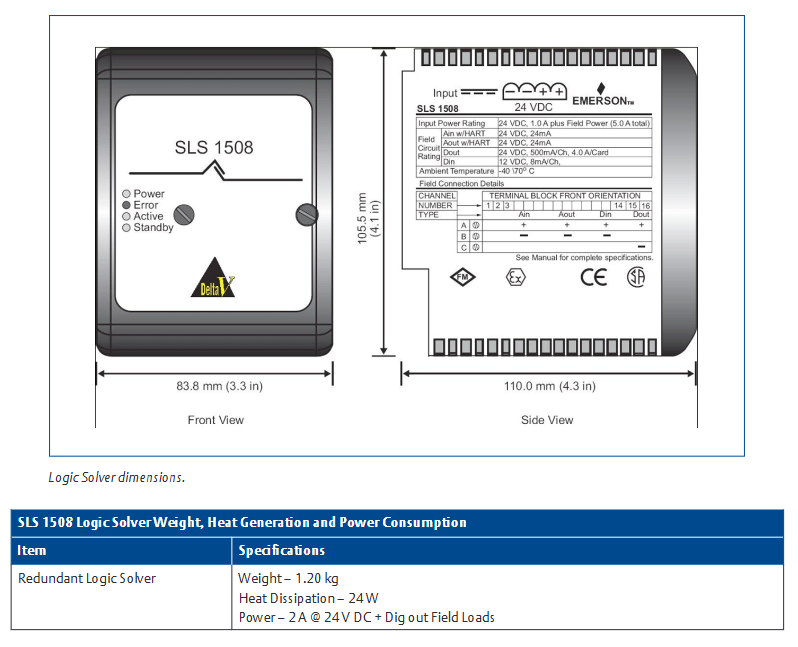

2. SLS1508 Physical and Electrical Specifications

Project parameter details

Input power supply 24V DC ± 20%, 1.0A (basic power consumption)+on-site power supply (total power consumption 5.0A); Suggest using an independent power supply with DeltaV controller/I/O

The maximum on-site power supply is 4A (actual value depends on channel type and on-site equipment)

Isolation level: Each channel is optically isolated from the system (1500VDC factory test), and there is no isolation between channels

No local bus current

Installation method: SIS (yellow) terminal block on a wide carrier with odd numbered slots; Redundant occupation of 4 slots

Redundancy for weight 1.20kg

Redundancy for heat consumption of 24W

Redundancy for 24V power consumption DC@2A +Digital output on-site load

Dimensions (Front/Side) 83.8mm (3.3 inches)/110.0mm (4.3 inches)

(2) Detailed parameters of I/O channels

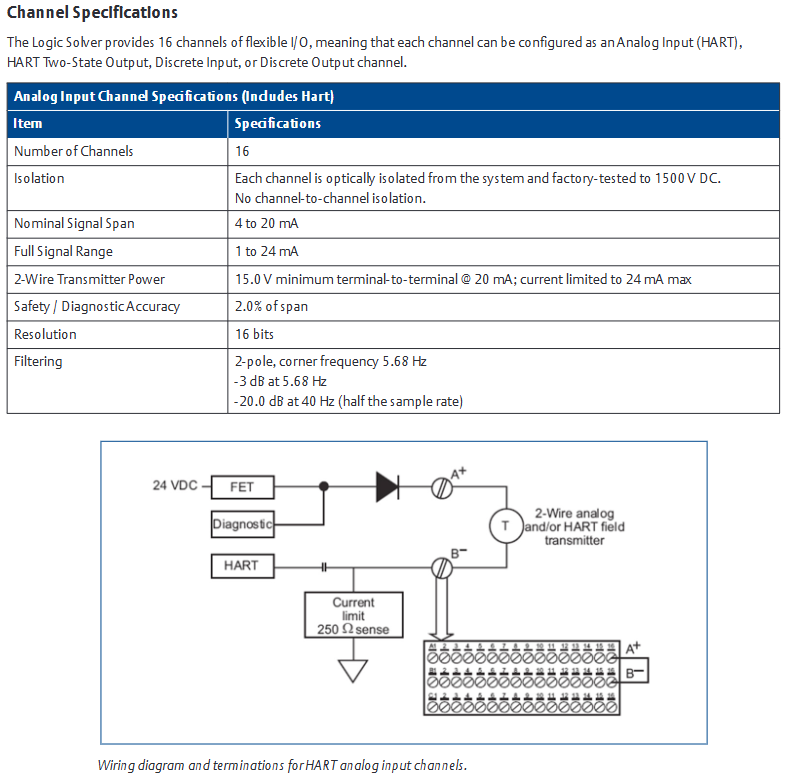

1. Analog input channel (including HART)

Project parameters

Number of channels 16

Isolate each channel from the system's optical isolation (1500VDC test), with no isolation between channels

Nominal signal range 4~20mA

Full signal range 1-24mA

When the 2-wire transmitter is powered by 20mA, the minimum voltage between terminals is 15.0V, and the maximum current limit is 24mA

2.0% of the safety/diagnostic accuracy range

Resolution 16 bits

Filter 2nd order, cut-off frequency 5.68Hz (-3dB), at 40Hz (1/2 of sampling rate) -20.0dB

2. HART dual state output channel

Project parameters

Number of channels 16

Isolate each channel from the system's optical isolation (1500VDC test), with no isolation between channels

The nominal signal range is 20mA for conduction and 0 or 4mA for shutdown (configurable)

Full signal range 0~24mA

5.0% of the safety/diagnostic accuracy range

Resolution of 12 bits

Compliant voltage 20mA@600 Ω load

Triggered when the open-loop detection output deviates from the configured value by 15% and the current is less than 1.0mA

3. Discrete input channel

Project parameters

Number of channels 16

Isolate each channel from the system's optical isolation (1500VDC test), with no isolation between channels

Conductivity detection ≥ 2mA

Shutdown detection ≤ 1.65mA

The input impedance is about 1790 Ω

Input compatibility NAMUR sensor (12V), dry contacts, dry contacts with terminal resistors

Line fault detection (short circuit, optional) with resistance<100 Ω and current>6mA

Line fault detection (open circuit, optional) with current<0.35mA when resistance>40k Ω

The fault detection configuration requires channel level activation, and the dry contact requires an external 12k Ω parallel resistor (open circuit detection) and a 2.4k Ω series resistor (short circuit detection). The NAMUR sensor does not require an external resistor

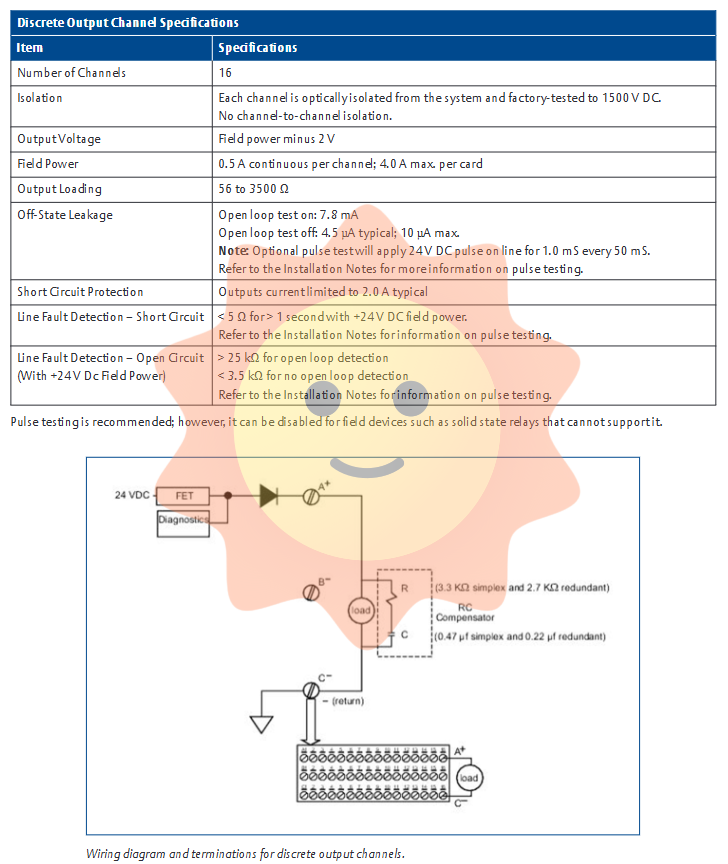

4. Discrete output channels

Project parameters

Number of channels 16

Isolate each channel from the system's optical isolation (1500VDC test), with no isolation between channels

Output voltage: On site power supply voltage -2V

On site power supply with continuous 0.5A per channel, maximum 4.0A per card

Output load 56~3500 Ω

Turn off leakage current open-loop test on: 7.8mA; open-loop test off: typical 4.5 μ A, maximum 10 μ A

Short circuit protection current limit typical 2.0A

Line fault detection (short circuit): Under 24V DC on-site power supply, the resistance is less than 5 Ω for more than 1 second

Line fault detection (open circuit): Under 24V DC on-site power supply, resistance>25k Ω (open circuit detection),<3.5k Ω (no open circuit detection)

Pulse testing is recommended to be enabled (apply 1ms of 24V DC pulse every 50ms), and devices such as solid-state relays that do not support it can be disabled

Ordering Information and Preconditions

(1) Core Product Order List

Product Description Model

DeltaV SLS1508 Redundant Logic Solver (including Terminal Block) VS3202

1 wide SISnet terminal component (including right expansion card and 2 terminal resistors) VS6051

SIS database extension VS1508

8-width carrier with expansion cable assembly (including left and right expansion cards, 2 logic solver communication buses coaxial, 1 carrier backplane communication cable) VE4050E1C2

2 Wide Carrier (Improved Type, Including Bus Terminal) VE3051C0

(2) Pre requirements

Software version: DeltaV v8.3 or above is required.

2-Width Power/Controller Carrier: Upgraded version after 2004 (with white rectangular markings on the board, located between the power module and MD controller), model KJ4001X1-BA3 and above; The old version (marked with white dots) does not support downloading logic solver programs.

MD controller: Model must be 12P2093X082 or above, early models do not support DeltaV SIS system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands