Aerotech EDU176 Ndrive HL series digital servo drive

Aerotech EDU176 Ndrive HL series digital servo drive

Product basic information

The manual begins by introducing the basic overview of the Ndrive HL series digital servo drive, including the product's functional positioning as a high-performance discrete drive option for the Automation 3200 motion system. It can drive various types of motors (brushless motor, brushed DC motor, and stepper motor) and perform current loop and servo loop closure to ensure positioning performance and speed stability. At the same time, basic information such as the version of the manual (Revision: 1.08b), release date (October 31, 2007), and related product number (P/N EDU176) were clarified.

System installation and configuration

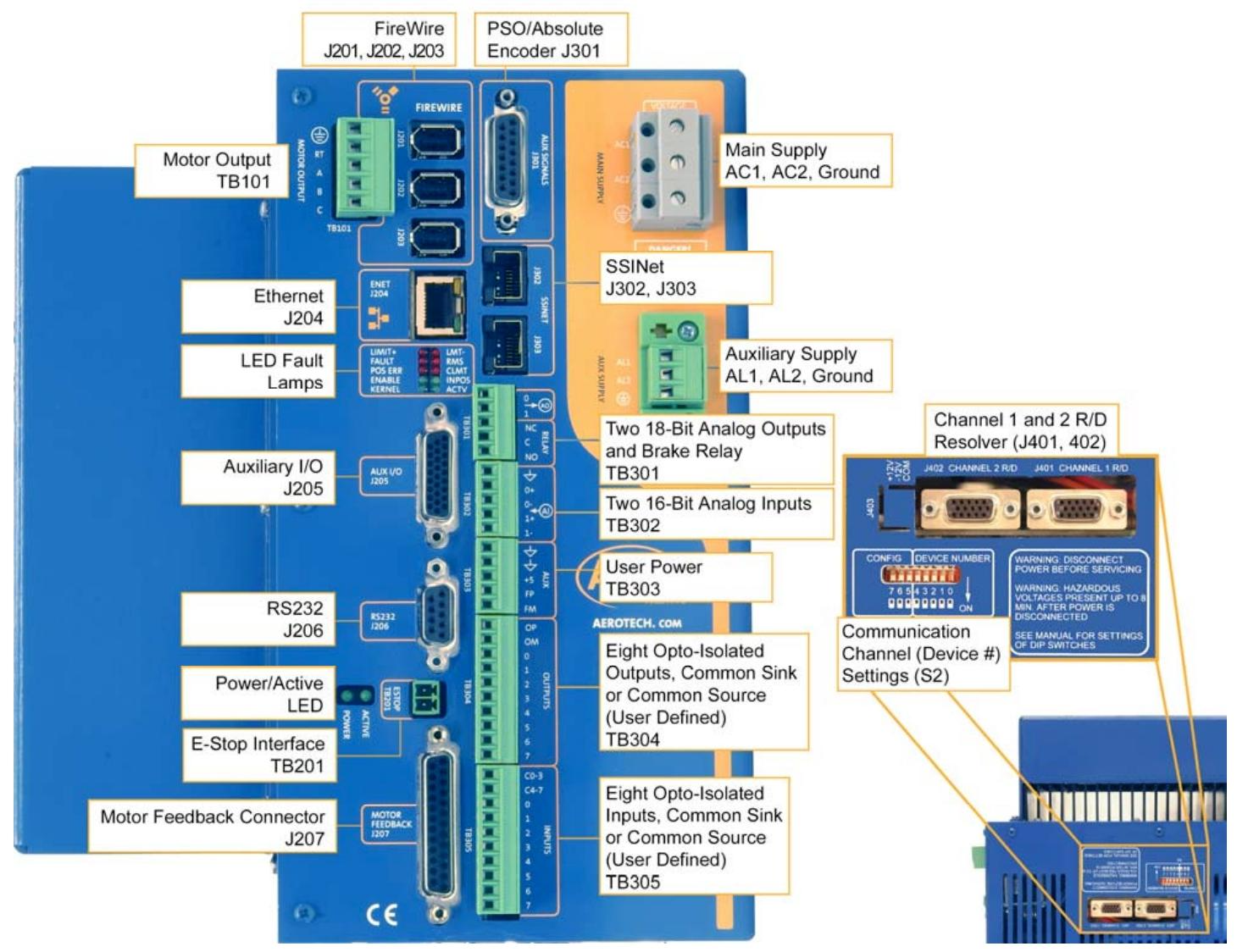

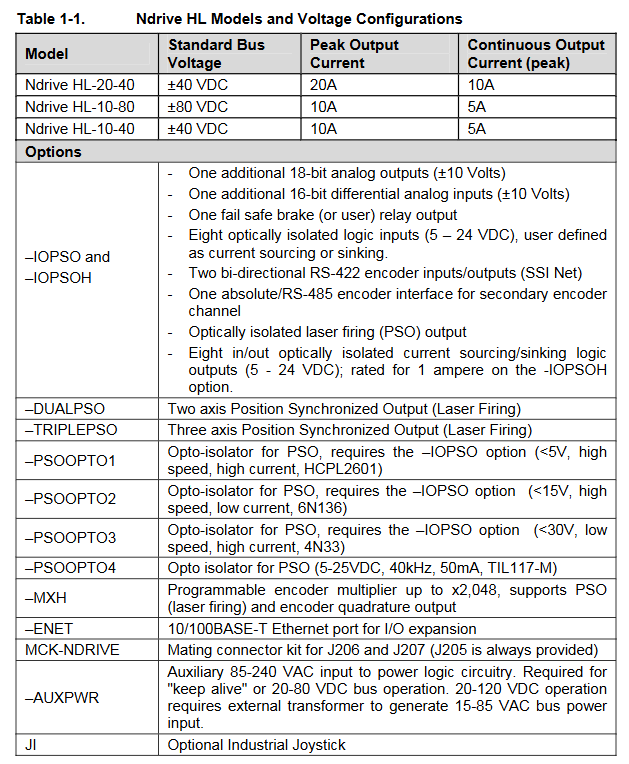

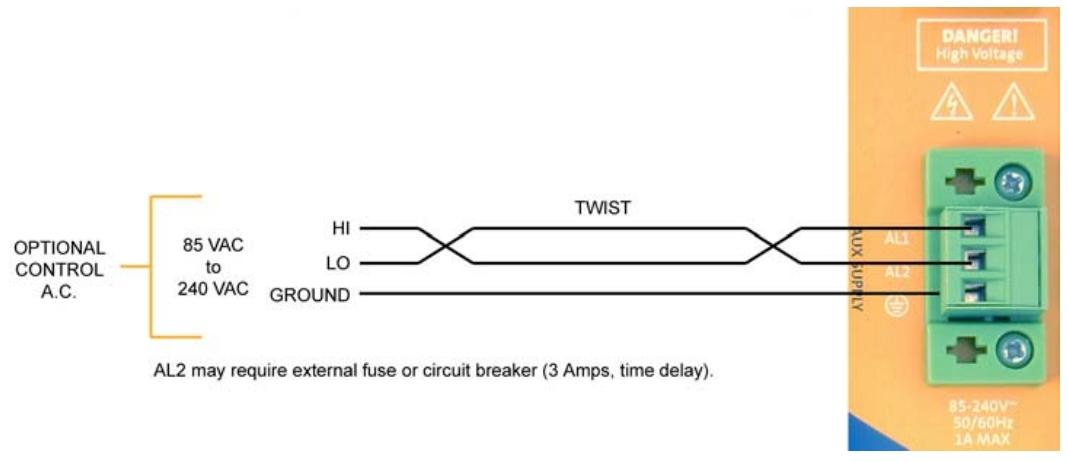

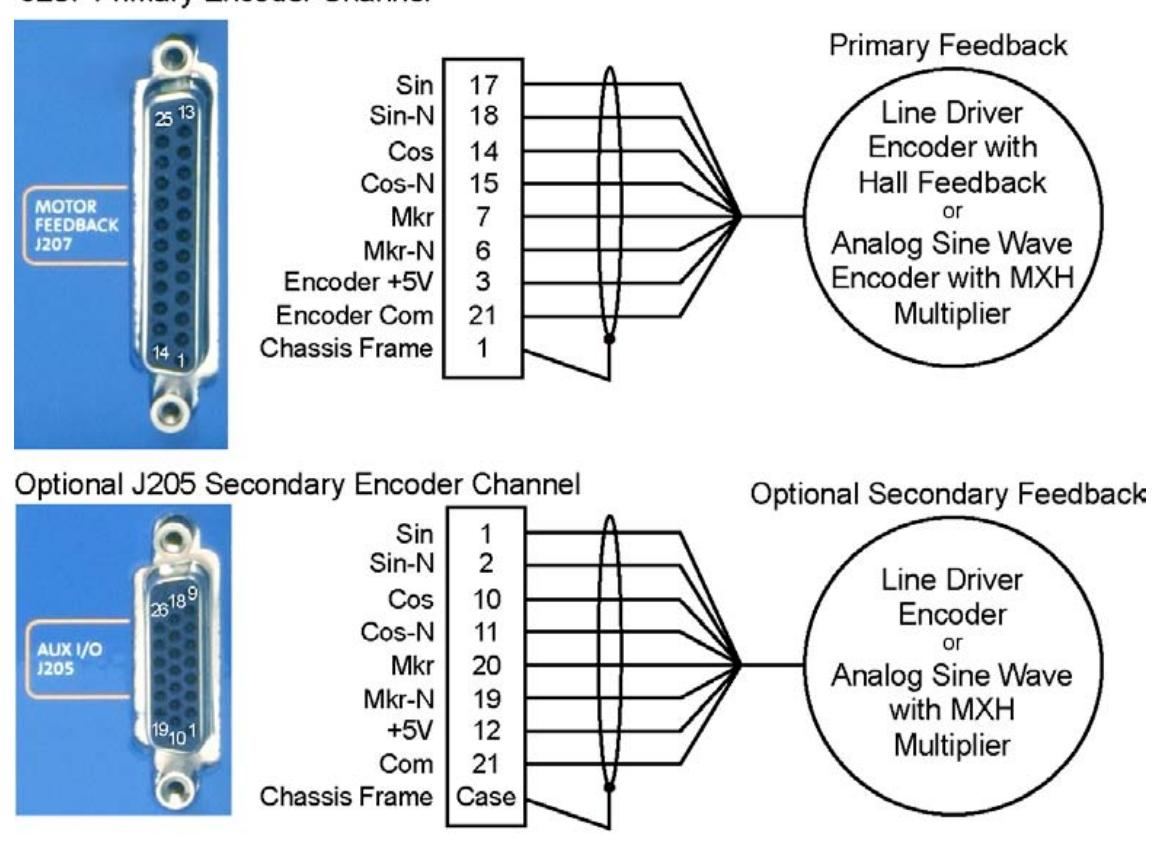

This section is an important component of the manual, detailing the specific steps and requirements for product installation and configuration. Including safety operating procedures, emphasizing precautions such as preventing electric shock and mechanical injury that must be followed during installation; The power connection method explains the wiring method, required wire specifications, and related protective measures for the motor power supply and control power supply (- AUXPWR option); Detailed wiring diagrams and phase adjustment methods are provided for different types of motors such as brushed DC motors, brushless motors, and stepper motors, including motor and feedback connections; Encoder feedback connection, introducing the phase adjustment and signal wiring of the encoder; And network configuration related content such as communication channel settings and multi drive connections.

Technical Details Explanation

Deeply analyzed the technical details of the Ndrive HL series products. Covering the pin allocation and functionality of the auxiliary I/O interface (J205), including analog input/output, digital input/output, and secondary encoder channels; Position synchronization output (PSO)/laser triggering function, explaining the working principle, triggering method, supported number of axes, and related parameter configuration of PSO; The pin definition of the motor feedback interface (J207) involves encoder signals, Hall effect signals, limit switch signals, etc; Communication protocol and pin allocation between RS-232/RS-422 ports and FireWire bus; It also includes parameter settings, hardware configuration, and fault handling for voltage current mode operation.

Optional Features and Accessories

Introduced the optional options and related accessories of the product. The optional options include - IOPSO and - IOPSOH expansion boards, - DUALPSO and - TRIPLEPSO laser triggering options, - ENET (Ethernet) options, - RDP rotary transformer input options, etc. The functions, hardware composition, and configuration methods of each option are described in detail. The attachment section lists the models, descriptions, and applicable scenarios of standard interconnect cables, as well as the connection methods for joystick and handwheel interfaces.

Troubleshooting and Maintenance

Provided diagnosis and solutions for common faults, listed in table form the possible causes and countermeasures for faults such as motor loss of control, amplifier alarm, overcurrent, overtemperature, etc; Introduced the testing points, jumper settings, and fuse information for key components such as the control board, motor power board, and power supply board; Explained the meaning of LED indicator lights, helping users determine the operating status of the device through the status of the indicator lights; It also includes recommendations for preventive maintenance, such as regularly checking cable connections, cleaning equipment, etc.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands