Aerotech Ndrive HP 10/20/30 Series Digital Servo Drive

Equipped with flexible redundancy design, supporting simplex, duplex, and triple module redundancy (TMR) systems, different levels of redundancy can be selected according to application requirements.

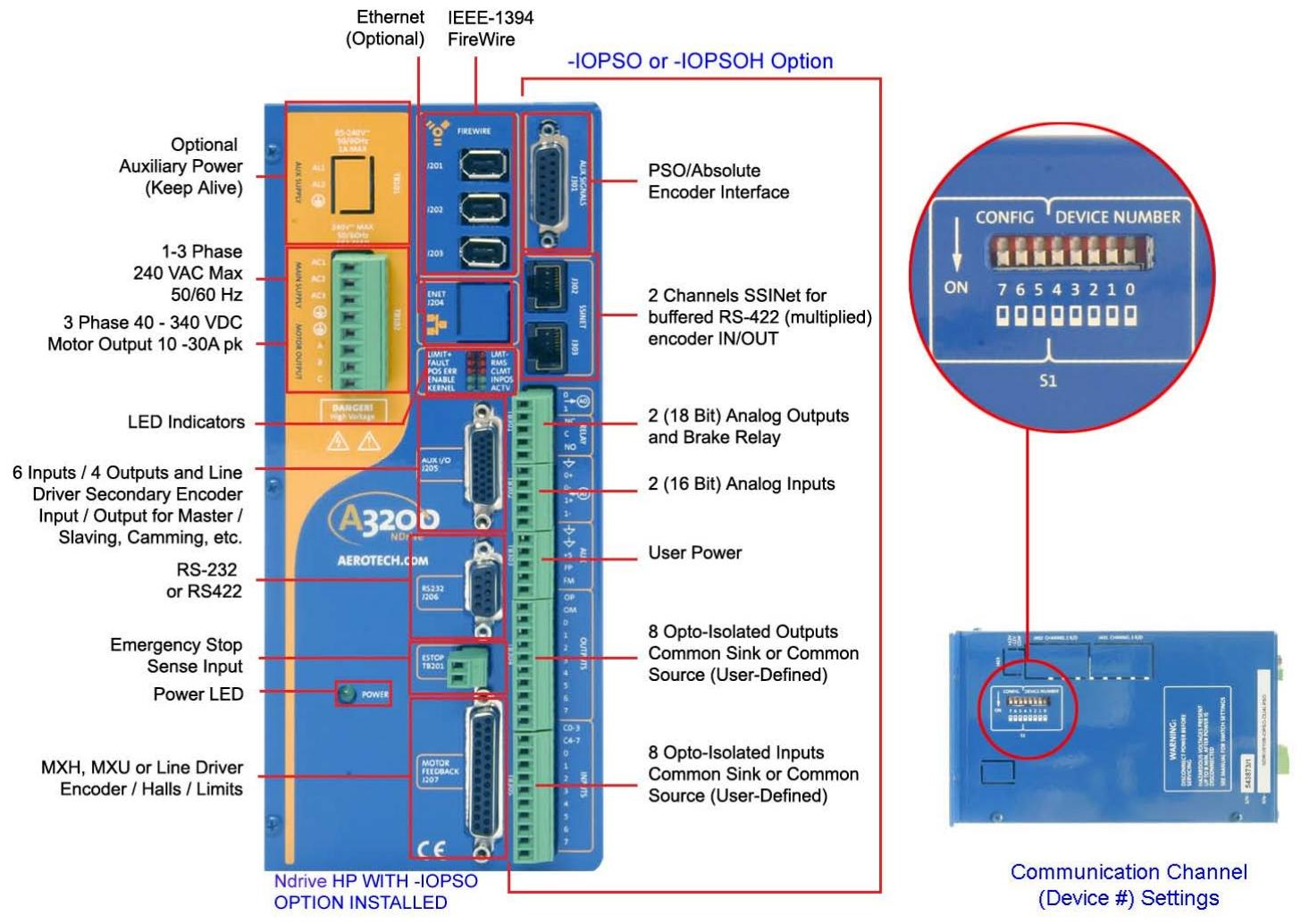

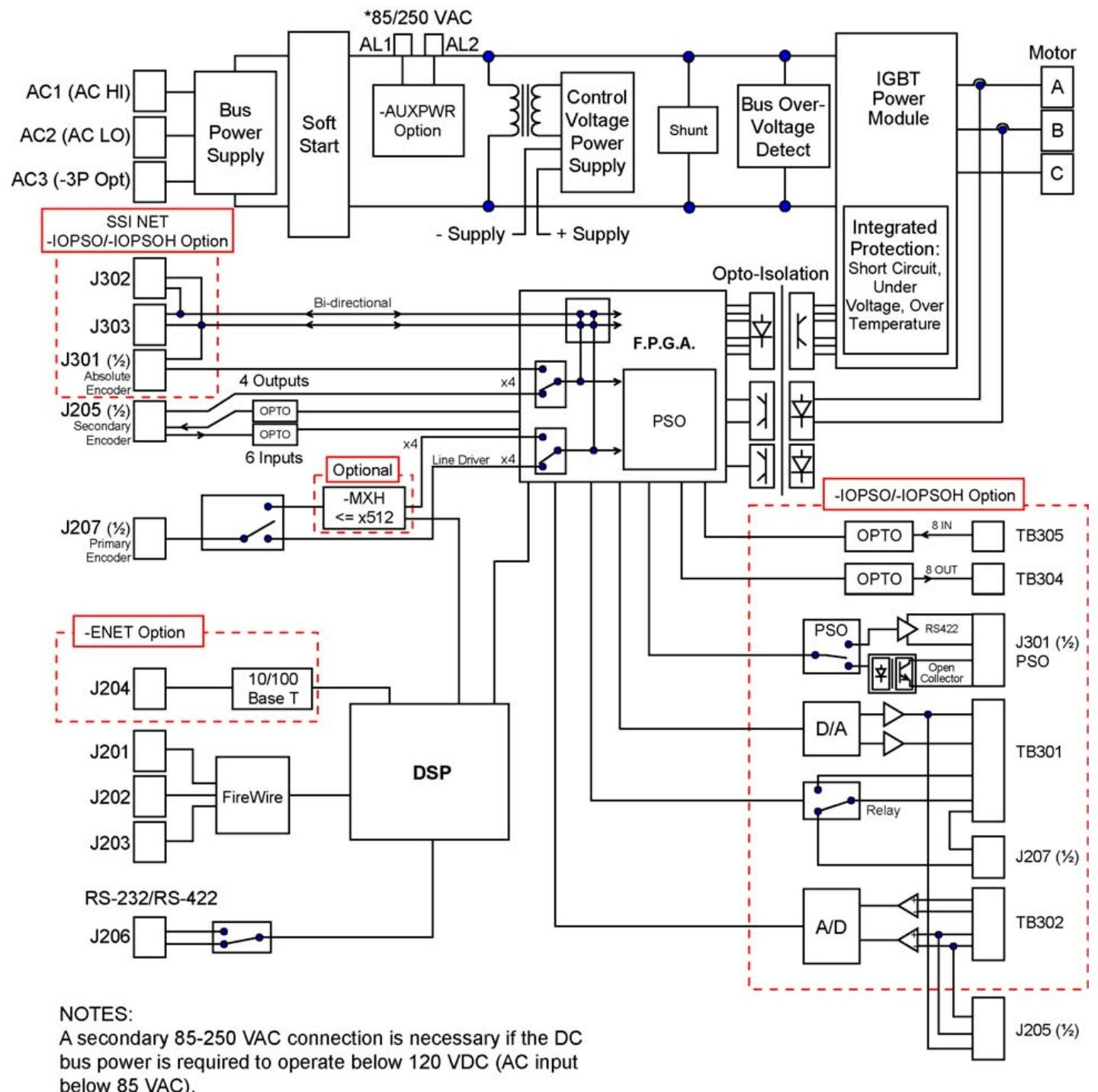

Provide rich I/O interfaces, including analog input/output, digital input/output, encoder feedback interface, etc., supporting high-speed user input (with a delay of about 50 nanoseconds).

Supports Position Synchronized Output (PSO)/laser triggering function, with a single axis triggering delay of 200 nanoseconds and a dual/three-axis triggering delay of 275 nanoseconds, enabling high-precision synchronous control.

Adopting IEEE-1394 (FireWire) ®) Communication bus, with a data transmission rate of 400Mbps, supports multi drive networking control, and can connect up to 32 axes.

Aerotech Ndrive HP 10/20/30 Series Digital Servo Drive

Product Overview

Functional Features

Suitable for brushless motors, brushed DC motors, and stepper motors, supporting full digital control of current loop, speed loop, and position loop, with a sampling rate of up to 20kHz.

Equipped with flexible redundancy design, supporting simplex, duplex, and triple module redundancy (TMR) systems, different levels of redundancy can be selected according to application requirements.

Provide rich I/O interfaces, including analog input/output, digital input/output, encoder feedback interface, etc., supporting high-speed user input (with a delay of about 50 nanoseconds).

Supports Position Synchronized Output (PSO)/laser triggering function, with a single axis triggering delay of 200 nanoseconds and a dual/three-axis triggering delay of 275 nanoseconds, enabling high-precision synchronous control.

Adopting IEEE-1394 (FireWire) ®) Communication bus, with a data transmission rate of 400Mbps, supports multi drive networking control, and can connect up to 32 axes.

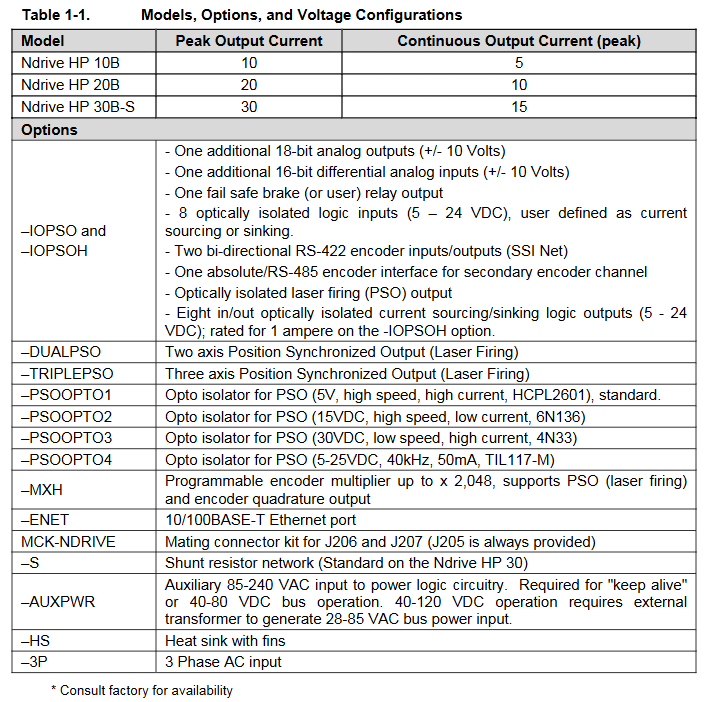

Model and specifications

It includes three models: Ndrive HP10, HP20, and HP30, with peak output currents of 10A, 20A, and 30A respectively, and continuous output currents of 5A, 10A, and 15A respectively.

The power input supports single-phase or three-phase AC, with a voltage range of 85-240VAC, a frequency of 50/60Hz, and a bus voltage range of 100-320VDC (optional 40-80VDC).

The working environment temperature is 0-50 ° C, the storage temperature is -20-70 ° C, the humidity is 5-95% (non condensing), and the highest altitude is 2000 meters.

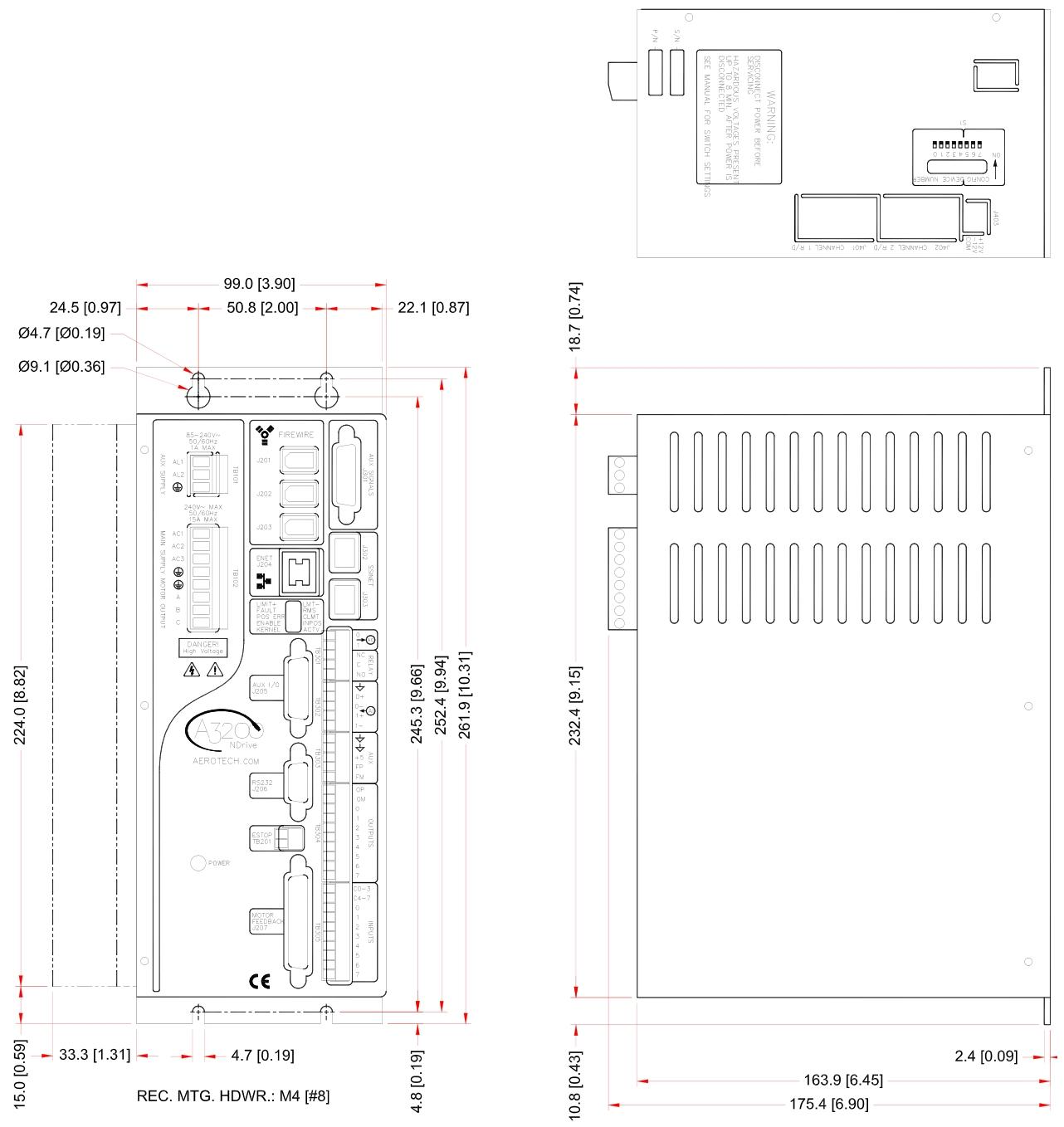

Installation and Configuration

Safety regulations: Emphasize electrical safety during installation, including precautions such as power-off operation, electric shock prevention, and mechanical injury prevention. Use cables and connectors that meet specifications.

Wiring and Grounding: Provide detailed instructions on the methods of power wiring (main power supply, control power supply), motor wiring, and feedback wiring (encoder, Hall sensor, etc.), emphasizing shielding and grounding techniques to reduce electromagnetic interference (EMI).

Motor configuration: Supports wiring and phase adjustment for brushed DC motors (torque mode, with speed feedback), brushless motors (Hall effect feedback, encoder feedback), and stepper motors, providing steps and methods for determining motor phase.

Communication settings: Set the communication channel number (1-32) of the drive through switch S2, supporting Daisy Chain or star topology of FireWire bus, and can connect up to 16 drives.

Technical Details

Auxiliary I/O interface (J205): Provides 4 optical isolated outputs, 6 optical isolated inputs (including 2 high-speed inputs), analog input/output, secondary encoder channels, supports RS-422 differential signals, and can be used for master-slave control or dual feedback systems.

Position Synchronization Output (PSO): Supports single axis, dual axis, and three-axis laser triggering, and can generate synchronization pulses based on encoder signals, external triggers, or software instructions. It has high triggering accuracy and is suitable for high-precision synchronization applications such as laser processing.

Motor feedback interface (J207): Supports differential line driven encoder, Hall effect sensor, limit switch, motor overheat thermistor input, encoder supports up to 8MHz signal (32MHz after fourth harmonic).

Communication interfaces: including RS-232/RS-422 (for firmware upgrade), FireWire (main communication bus), optional Ethernet interface (- ENET option), supporting ModBus TCP protocol.

Voltage current mode: supports independent operation mode, controls motor current through analog input (± 10V), suitable for use with external controllers, requires configuration of relevant parameters and saving to flash memory.

Optional Features

-IOPSO and - IOPSOH Options Board: Extended I/O interfaces, including 8 optically isolated inputs/outputs, 2 18 bit analog outputs, 2 16 bit differential analog inputs, SSI network interfaces, absolute encoder interfaces, and brake relays. - IOPSOH supports higher output currents (1A/channel).

-DUALPSO and TRIPLEPSO options: Supports dual axis/three-axis laser triggering, requiring the transmission of encoder signals from other axes through SSI network or auxiliary encoder channels, with a maximum tracking rate of 5MHz.

-ENET option: Provides 10/100BASE-T Ethernet ports, supports ModBus TCP protocol, and is used to connect third-party I/O modules.

-RDP Rotary Transformer Input Options: Supports 1-2 ways of rotary transformer or induction synchronizer input, with optional carrier frequencies of 10kHz, 7.5kHz, and 5kHz. Phase and gain parameters need to be configured.

-MXH option: Encoder resolution multiplier, supporting up to x2048 multiplication (up to x8192 when combined with fourth harmonic), suitable for high-precision positioning, with a maximum input frequency of 200kHz.

Accessories and Troubleshooting

Standard cables: Provide models and specifications of motor cables, feedback cables, SSI network cables, etc., supporting different lengths and connector types.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands