ABB NextMove ESB-2 motion controller

ABB NextMove ESB-2 motion controller

Product positioning

NextMove ESB-2 is a high-precision multi axis intelligent controller that supports servo motor and stepper motor control. It is suitable for automated production lines, precision machinery, and other scenarios, and uses Mint programming language to achieve complex motion control (such as point-to-point motion, electronic gears, cam synchronization, etc.).

Product Overview and Core Features

1. Model and classification

According to the number of servo axes, serial interface type, and stepper output type, there are 8 models, with the following core differences:

Model series, number of servo axes, number of stepper axes, additional encoder input, serial port, stepper output type

NSB202、3、4、2、RS232/485、 Differential Output

NSB203、3、4、2、RS232/485、 open collector

NSB204、4、4、1、RS232/485、 Differential Output

NSB205、4、4、1、RS232/485、 open collector

2. Core functions

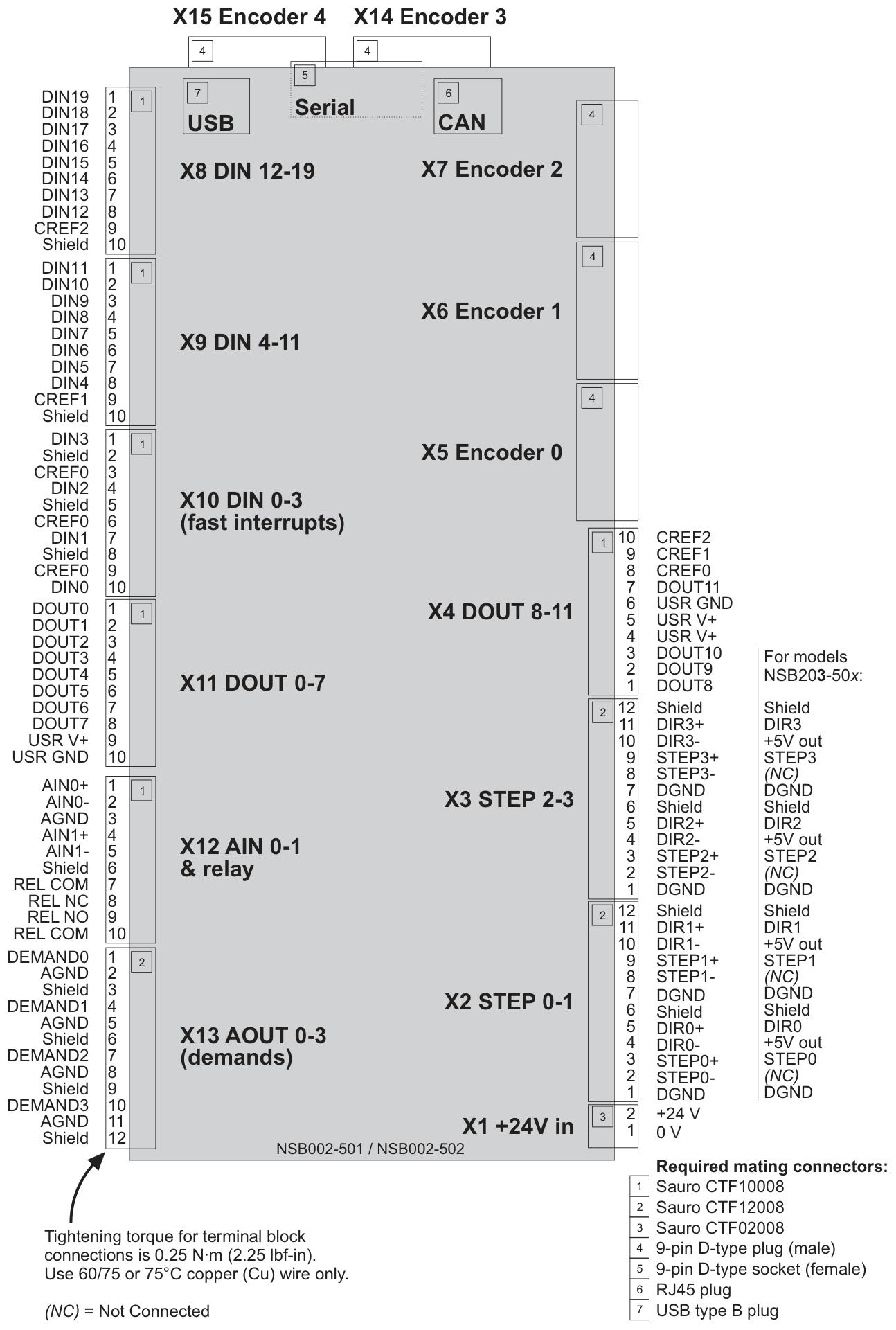

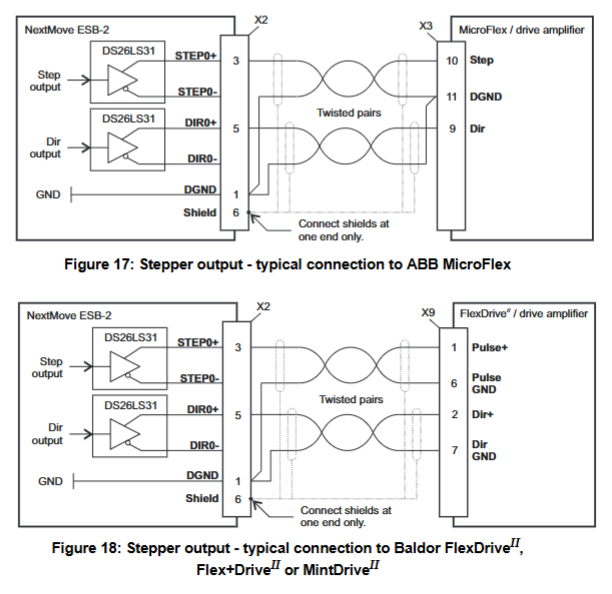

Multi axis control: Supports 4 stepper axes+3/4 servo axes (model dependent), supports complex motion modes such as master-slave following and electronic gears.

Rich I/O interfaces: 20 digital inputs, 12 digital outputs, 2 12 bit analog inputs, 4 12 bit analog outputs, suitable for various sensors and actuators.

Communication capability: comes standard with USB 1.1, RS232/RS485, CANopen (compatible with third-party devices), and Baldor CAN (proprietary protocol).

Programming flexibility: Based on Mint language (Structured Basic), it supports rapid development of simple motion programs and complex synchronous control logic.

Hardware and interface configuration

1. Power supply and installation

Power supply requirements:+24V DC (± 20%), continuous current of 2A, it is recommended to configure an independent power supply with 4A fuses.

Installation environment: Operating temperature of 0-45 ℃, relative humidity ≤ 80% (no condensation), vertical installation on non flammable surfaces, with a reserved heat dissipation space of ≥ 20mm around.

Mechanical dimensions: 245mm × 140mm × 45mm, weighing approximately 700g, fixed with M4 screws.

2. Key interface parameters

Analog input: differential input, ± 10V range, 12 bit resolution, input impedance of 120k Ω, maximum sampling rate of 4kHz

Analog output: Single ended output, ± 10V range, 12 bit resolution, maximum output current of 2.5mA, update frequency up to 10kHz

Digital input: Optocoupler isolation, supports level/edge triggering, 3 sets of common terminals (CREF0/1/2), input voltage 12~30V DC

Digital output: Maximum total current 500mA (DOUT0-7)/500mA (DOUT8-11), supports driving relays, solenoid valves, etc

Encoder input: Supports 5 incremental encoders (A/B/Z phase), RS422 differential signal, maximum input frequency 10MHz

CAN interface: Supports CANopen and Baldor CAN protocols, with a maximum baud rate of 1Mbps, requiring 12-24V power supply (optocoupler isolation)

Serial interface: RS232 (up to 115.2KBaud)/RS485 (supports multi machine cascading), USB 1.1 (compatible with USB 2.0/3.0)

Software and Programming Guide

Development Environment and Tools

1. Core software components

Mint WorkBench: An integrated development environment (IDE) used for programming, debugging, parameter configuration, and motion monitoring, supporting Windows XP and above systems (32/64 bit). The main functions include:

Code editing and syntax checking

Real time data collection and graphical display (position, velocity, current, etc.)

Axis parameter configuration and servo tuning

Firmware Update and System Diagnosis

Mint Machine Center (MMC): Used for managing multi controller networks, supporting scanning and connecting multiple NextMove ESB-2 nodes, creating visual system layouts, and saving workspace configurations.

2. Software installation and connection

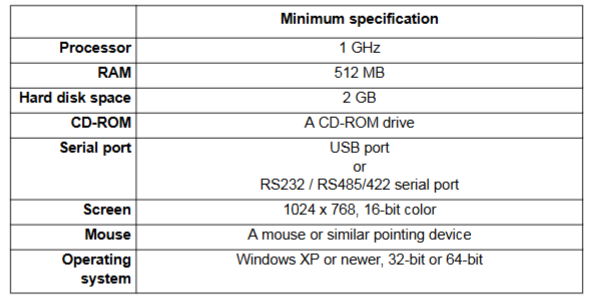

Installation requirements: The PC must meet the minimum configuration (1GHz processor, 512MB memory, 2GB hard disk space, USB or serial port), and administrator privileges are required for installation.

Connection method:

USB: Connect directly through USB Type B interface and automatically install drivers (compatible with Windows XP/Vista/7).

Serial port: RS232 (maximum 3m cable) or RS485 (supports multi machine cascading, requires terminal resistance matching).

Network: Connect distributed nodes through CANopen or Baldor CAN protocol.

Fundamentals of Mint Programming Language

Language characteristics

Mint is a structured language designed specifically for motion control, based on Basic syntax and extending motion control specific commands. Its features include:

Multi axis support: Control objects are distinguished by axis numbers (0-7), and multiple axes can be operated simultaneously.

Real time performance: The cycle time can be configured (1ms or 2ms) to ensure efficient execution of motion instructions.

Rich library functions: covering specialized commands such as point motion, speed control, synchronous following, etc

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands