ABB PFCL 201 series pillow block weighing sensor

ABB PFCL 201 series pillow block weighing sensor

Product positioning

PFCL 201 series sensors are based on Presductor ® High precision force measurement equipment for technology is mainly used for tension detection of coils (such as paper, metal strips, plastic films) in medium and high voltage industrial environments. By measuring the vertical reaction force generated by coil tension, precise control of the production process is achieved.

Product Overview and Core Features

1. Model and classification

The PFCL 201 series includes three models, divided by structure and environmental adaptability:

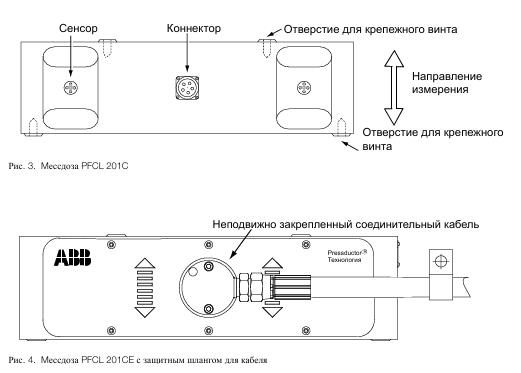

PFCL 201C: Basic model, equipped with detachable cable connectors, suitable for conventional environments;

PFCL 201CE: Cable with fixed protective hose, enhanced mechanical protection, suitable for vibration scenarios;

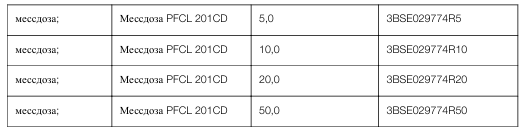

PFCL 201CD: Made of acid resistant PTFE insulated cable and stainless steel material (1.4404), suitable for corrosive environments.

All three models support four ranges of 5kN, 10kN, 20kN, and 50kN, meeting the needs of different tension scenarios.

2. Measurement principle

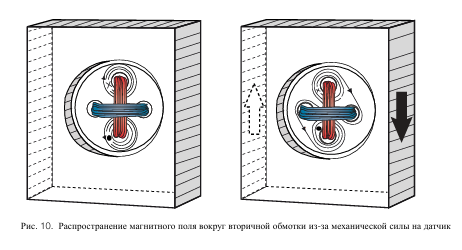

Based on the magnetostrictive effect: The sensor core is a magnetostrictive diaphragm integrated in a steel block. The primary winding is fed with 330Hz AC power to generate a magnetic field, and the secondary winding induces a voltage signal proportional to the tension due to mechanical force. It is only sensitive to forces in the vertical direction (measurement direction) and has strong anti-interference ability against lateral and axial forces (with an allowable error of ≤± 0.5%).

3. Key technical parameters

Parameter specification range

Accuracy level ± 0.5% FS

Linear deviation<± 0.3% FS

Lag error<0.2% FS

Working temperature range -10~+90 ℃

Compensation temperature range+20~+80 ℃

Overload capacity (without permanent deformation) 10 times the rated load (up to 500kN for 50kN models)

Material: Stainless Steel (1.4104)/Acid Resistant Steel (1.4404)

Protection level IP65 (CE/CD model)

System composition and installation specifications

1. System composition

The complete measurement system includes:

Two weighing sensors (used in pairs, symmetrically installed at both ends of the roller shaft);

Junction box (PFXC 141, signal aggregation and protection);

Control unit (such as PFEA 111/112/113, outputting tension signal);

Adapt cables and installation accessories (adapter board, high-strength screws, etc.).

2. Installation requirements

Mechanical installation:

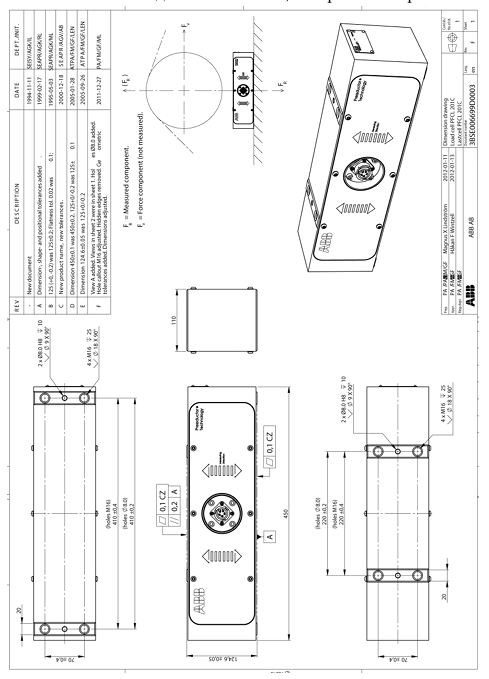

Installation surface flatness error ≤ 0.05mm, adapter plate thickness ≥ 30mm (5-20kN model) or ≥ 35mm (50kN model);

The sensor is fixed with 4 M16 screws (recommended 12.9 grade alloy screws, torque 170-286Nm) to avoid deformation of the base due to over tightening;

Horizontal or inclined installation is allowed (inclination angle ≤ 30 °), and the measurement force needs to be corrected through the angle compensation formula when tilting (see manual 2.5.3).

Electrical connection:

The cable needs to be twisted pair shielded, with the shielding layer grounded at one end (length ≤ 50mm) and a distance of ≥ 30cm from the power cable;

The primary winding provides a power supply of 0.5A/330Hz, and the secondary signal output impedance is 9-12 Ω, with strong anti-interference ability.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands