Foxboro Evo FBM237 Analog Output Module

Compliance certification and security requirements

(1) Core certification

The FBM237 module and its supporting TA comply with global safety, electromagnetic compatibility, and environmental standards in multiple regions, with the following core certifications:

Specific standards and levels for certification categories

Hazardous Area Certification North America: UL/UL-C Class I Division 2 Groups A-D, Temperature Code T4;

Europe: ATEX 2014/34/EU II 3 G Ex nA IIC T4 (DEMKO certification, except RH917QZ);

International: Compliant with IECEx standards and suitable for Zone 2 hazardous areas

Electromagnetic Compatibility (EMC) EU EMC Directive 2014/30/EU, compliant with EN 61326-1:2013 Class A (Emission and Immunity in Industrial Environments)

Low Voltage Safety EU Low Voltage Directive 2014/35/EU, communication circuits comply with UL Class 2 standards (NFPA 70 Article 725, CSA C22.1 Section 16)

Environmental compliance complies with the EU RoHS 2011/65/EU directive, restricting the use of harmful substances such as lead and mercury

Ship certification ABS type approval, French Classification Society (BV) EC31 environmental category certification, applicable to ship automation systems

(2) Safety operation requirements

Electrical safety:

Isolation restriction: Although the module can withstand 600V AC, it is prohibited to connect to excessive voltage (such as 220V AC) for a long time to avoid insulation damage;

Wiring specifications: On site wiring should distinguish between positive and negative poles. In redundancy mode, ensure that the two modules have independent power supplies to prevent redundancy failure caused by single point power failure.

Dangerous area operation:

Shell requirements: It must be installed in a certified shell with a protection level of IP54 or above, and the shell must be opened with tools to prevent unauthorized operation;

Maintenance process: Power off or confirm that the area is in a non hazardous environment before connecting/disconnecting cables. Redundant module replacement should be carried out after the faulty module is powered off.

Upgrade and compatibility instructions

FBM237 is mainly used to replace the Foxboro 100 series FBM37 analog output module. When upgrading, the following compatibility points should be noted:

Hardware replacement: A single FBM237 can directly replace one FBM37, and on-site wiring can be reused in two ways:

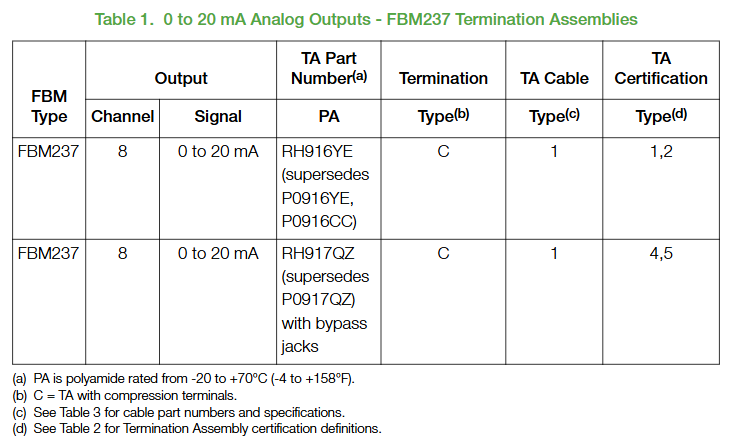

Direct adaptation: Use the documentation to specify the TA (such as RH916YE) and rewire it to the TA terminal;

Adapter reuse: Connect the terminated component adapter (TAA, refer to PSS 31H-2W4) directly to the original FBM37 wiring without rewiring.

Software adaptation:

Should be paired with Foxboro Evo control software v8. x+or Control Core Services v9.0+, supporting AOUTR redundant function block configuration;

The failure safety parameters need to be pre-set in the software (such as a fallback current of 0mA and a fault delay time) to ensure that the actuator is in a safe state in case of a fault.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands