Foxboro Evo FBM237 Analog Output Module

Key Features

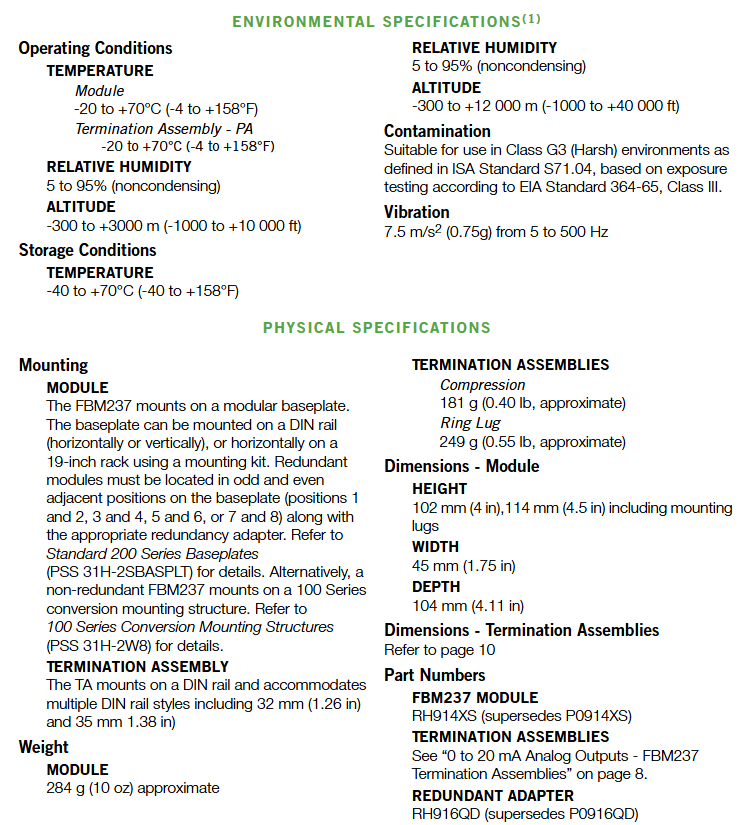

Environmental adaptability: Complies with ISA S71.04 G3 level harsh environmental standards, can withstand vibration (0.75g @ 5-500Hz), wide temperature range (working -20~70 ℃, storage -40~70 ℃), and is suitable for industrial high temperature and high dust scenes;

Hot plugging and maintenance: Module replacement does not require dismantling of on-site wiring, power or communication cables, and redundant module maintenance does not affect the operation of on-site equipment; Partial termination components (TA) with bypass sockets, supporting temporary output maintenance through bypass stations (such as P0900HJ);

Status indication: The front LED light provides real-time feedback on the communication status, power status, and channel faults of the module, making it easy to quickly locate problems;

Communication reliability: Connected to the fieldbus communication module (FCM) or control processor (FCP) through a 2 Mbps redundant fieldbus, supporting A/B dual path switching, and ensuring uninterrupted data transmission in case of single path failure.

Hardware parameters and technical specifications

(1) Output and precision parameters

Parameter category specific specifications

Channel configuration includes 8 independent channels, with each channel being Galvanically isolated (between channels, channel to ground)

Accuracy (including linearity) ± 0.05% range (within the range of 0.1~20mA), temperature coefficient ± 50 ppm/℃ (temperature changes have little impact on accuracy)

Maximum output delay of 30ms (meets the real-time requirements of most industrial controls)

Resolution of 13 bits (high output adjustment accuracy, supports fine control signal output)

Circuit power supply protection with independent current limitation and voltage regulation for each channel to avoid overload damage

The wiring distance depends on the compliant voltage (18V DC at 20.4mA), wire specifications, and equipment voltage drop, and supports a maximum of 30m cables

(2) Power supply and power consumption

Power input: 24V DC (redundant mode, allowable range+5%/-10%, i.e. 21.6-26.4V DC), requires independent redundant power supply;

Power consumption: Maximum 7W (running) at 24V DC, maximum heat dissipation of 5W, reserved heat dissipation space is required to avoid module overheating.

(3) Physical and environmental parameters

Parameter category specification requirements

Dimensions (module) height 102mm (including installation ears 114mm) x width 45mm x depth 104mm, single slot design

The weight module weighs approximately 284g (10oz); TA approximately 181-249g (0.40-0.55lb, depending on terminal type)

Working environment temperature -20~70 ℃, humidity 5%~95% (non condensing), altitude -300~3000m

Storage environment temperature -40~70 ℃, humidity 5%~95% (no condensation), altitude -300~12000m

The pollution level complies with EIA 364-65 Class III and is suitable for harsh environments with ISA S71.04 G3 level (high dust, high humidity)

Installation and Termination Component (TA) Configuration

FBM237 needs to be used in conjunction with a dedicated base, termination assembly (TA), and cables. Installation and wiring must follow strict specifications, with the following core requirements:

(1) Base and installation

Base type:

Modular base: Supports DIN rail (32mm/35mm) or 19 inch rack installation, with a maximum capacity of 8 FBM modules per base;

Redundant installation: Redundant modules need to be fixed in adjacent odd/even positions, connected to the base terminals through the redundant adapter RH916QD, to achieve two modules sharing one TA signal interface.

Installation specifications:

Heat dissipation space: Reserve ≥ 25mm space on each side of the module to avoid the influence of adjacent devices on heat dissipation;

Grounding requirements: Galvanized yellow chromium steel DIN rails are preferred for the base to ensure reliable grounding, and aluminum/plastic rails are prohibited (which may cause poor grounding).

(2) Termination Component (TA) Selection

TA is a key component connecting FBM237 with on-site actuators, providing signal switching and bypass maintenance functions. It needs to be selected according to the scenario, and the specific model and adaptation scenario are as follows:

TA model core function adaptation scenario authentication type

RH916YE (main TA) 8-channel signal transfer, no bypass function, normal scenario (no online maintenance required) Type 1/2 (compatible with hazardous areas)

RH917QZ (main TA) 8-channel with bypass socket, supporting bypass station access to critical scenarios (requiring online maintenance, such as chemical reaction kettle) Type 4/5 (ordinary area+Class 2 circuit)

TA connection: TA connects to the base through a Type 1 cable (25 pin D-sub interface), with a maximum cable length of 30m, supporting 2 materials:

P/PVC: polyurethane outer layer+PVC insulation, temperature range -20~80 ℃, suitable for ordinary industrial environments;

LSZH (Low Smoke Zero Halogen): Low smoke zero halogen release at high temperatures, suitable for enclosed environments such as ships and subways, with a temperature range of -40~105 ℃;

Wiring specifications: TA supports solid/multi strand wires of 0.2~4mm ² (24~12 AWG), and multi strand wires with wire ears should be 0.2~2.5mm ² (with or without plastic sleeves), with terminal torque in accordance with manufacturer specifications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands