Foxboro Evo ™ FBM242 Discrete Output Module

Foxboro Evo ™ FBM242 Discrete Output Module

Module Core Overview

FBM242 is Schneider Electric Foxboro Evo ™ The external power supply discrete output module in the process automation system has 16 discrete output channels, which can adapt to common voltages and currents in industrial scenarios. It requires an external power supply to power the field circuit and can achieve electrical output signal interaction between the control processor and field devices. It supports digital I/O applications (including ladder logic) and provides output fault safety configuration options.

Key characteristics

Channel and voltage support: Includes 16 discrete output channels, compatible with various voltage signals including 15-60V DC, 120V AC/125V DC, and 240V AC.

Isolation protection: Each input and output adopts galvanic isolation (electrical isolation), and when combined with external excitation, it is group isolation, which can avoid interference between different channels and ground.

Environmental adaptability: Adopting a sturdy design, the shell is made of extruded aluminum, which can be installed in G3 level (harsh) environments that comply with ISA standard S71.04, and can withstand vibration (7.5m/s ², 5-500Hz).

Configurable functions: When executing discrete I/O or ladder logic programs, options such as input filtering time, fail safe configuration, fail safe fallback, and continuous/instantaneous output can be configured.

Visual indication: The front of the module is integrated with LED indicator lights, which can display the running status of the module and the discrete status of each output point, facilitating real-time monitoring.

Convenient maintenance: Modules can be disassembled and replaced without dismantling on-site equipment wiring, power or communication cables, reducing maintenance downtime.

Communication redundancy: Connected to the fieldbus communication module (FCM) or control processor (FCP) through a redundant 2Mbps fieldbus, the two communication paths (A/B) can automatically switch to ensure communication continuity.

Safety design: The on-site power supply of contacts or solid-state switches has current limiting protection to ensure the safety of equipment and personnel.

Detailed technical specifications

(1) Output channel parameters

Parameter values

Number of channels: 16 isolated channels

Maximum application voltage 15-60V DC

Load current single channel maximum 2.25A

At surge current of 30 ° C, the maximum current in a single channel within 20ms is 8A; at 70 ° C, the maximum current in a single channel within 20ms is 6.4A

Maximum 0.2V when the on state voltage drop is 2.25A

Maximum open state leakage current of 0.1mA

Inductive load protection requires connecting protective diodes or metal oxide varistors (MOVs) at both ends of the inductive load

Isolate and withstand voltage between any channel and ground, between any two channels, apply 600V AC voltage for 1 minute without damage (note: do not operate at this voltage for a long time, otherwise it violates safety regulations and poses a risk of electric shock)

(2) Power supply and power consumption

Input voltage range (redundant): 24V DC (± 5%/-10%)

Maximum power consumption: 3W at 24V DC

Maximum heat dissipation: 6.5W when 24V DC and all outputs are 1.5A

(3) Environmental specifications

Environmental Condition Module Terminal Component (PA)

Working temperature -20 to+70 ° C (-4 to+158 ° F) -20 to+70 ° C (-4 to+158 ° F)

Working humidity 5% -95% (non condensing) 5% -95% (non condensing)

Working altitude -300 to+3000m (-1000 to+10000ft) -300 to+3000m (-1000 to+10000ft)

Storage temperature -40 to+70 ° C (-40 to+158 ° F) -40 to+70 ° C (-40 to+158 ° F)

Storage humidity 5% -95% (non condensing) 5% -95% (non condensing)

Storage altitude -300 to+12000m (-1000 to+40000ft) -300 to+12000m (-1000 to+40000ft)

(4) Physical specifications

Installation method: The module is installed on a modular base plate, which can be DIN rail mounted (horizontal/vertical) or horizontally mounted on a 19 inch rack through an installation kit; The terminal assembly (TA) is installed on a DIN rail (compatible with 32mm and 35mm specifications).

Weight: The module weighs approximately 284g (10oz); The weight of terminal components varies depending on their specifications, with the 127mm model weighing approximately 272g (0.60lb), the 148mm model weighing approximately 285g (0.65lb), and the 216mm model weighing approximately 320g (0.70lb).

Module dimensions: height 102mm (4in, including installation ears 114mm/4.5in), width 45mm (1.75in), depth 104mm (4.11in); The size of the terminal component should refer to the corresponding model (such as RH917XX width 127mm, etc.).

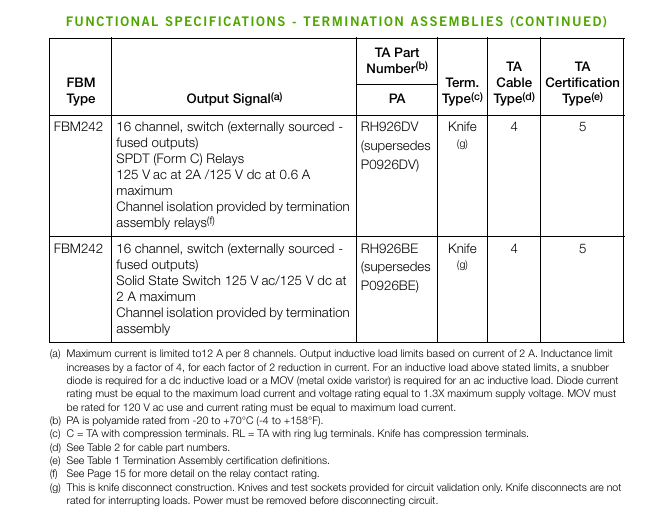

Terminal Components (TAs) Details

(1) Core functions

The terminal components are installed through DIN rails to connect the on-site I/O signals with the FBM subsystem, providing functions such as signal conditioning, surge light isolation, external power connection, and fuse protection. In most scenarios, no additional terminal equipment is required.

(2) Classification and specifications

Low voltage discrete output TA: suitable for<60V DC voltage, with split band fuse protection (single channel 3.15A filled fuse, current limiting 2A) and no fuse protection (users need to configure intermediate relays or fuse terminal blocks between TA and on-site equipment themselves). The power supply can come from FBM 24V DC auxiliary power supply or on-site power supply.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands