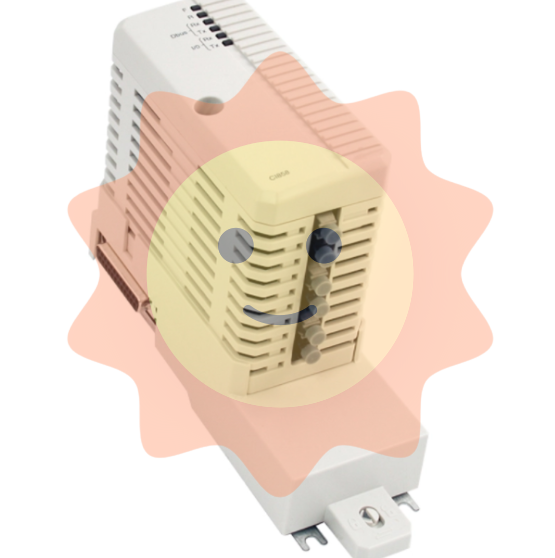

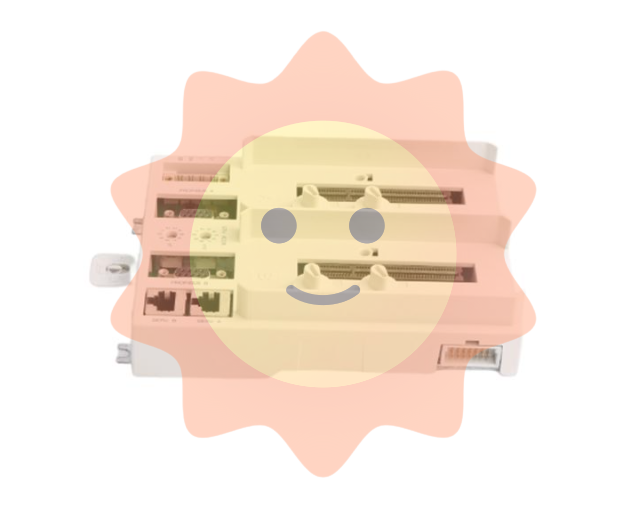

Yokogawa STARDOM FCN-500 Autonomous Controller

Process control: supports continuous control (PID regulation, ratio control), sequential control (logical interlocking, step control), and adapts to complex industrial processes (such as temperature control of chemical reaction vessels and pressure regulation of oil and gas pipelines);

Data acquisition and measurement: Real time acquisition of analog quantities (4-20mA, RTD/TC temperature signals), digital quantities (24V DC switch signals), and pulse quantities (frequency/pulse counting), with a measurement accuracy of ± 0.1% FS, meeting industrial grade metrology requirements;

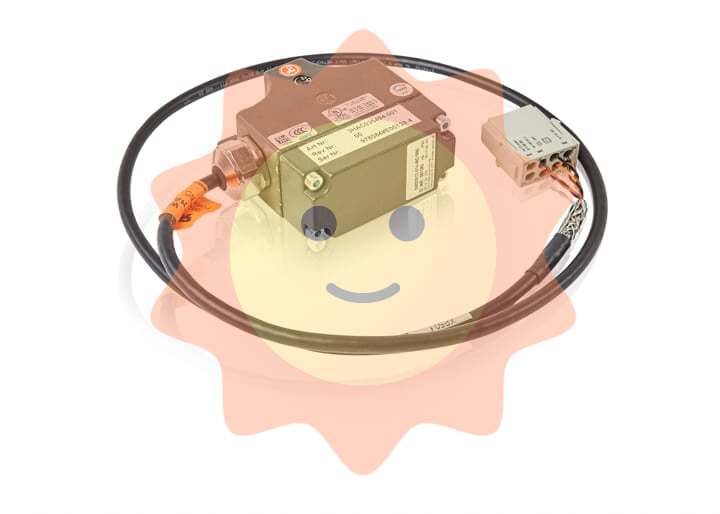

Multi protocol communication: compatible with mainstream industrial buses such as FOUNDATION Fieldbus, HART, Modbus, PROFIBUS-DP, CANopen, etc., supporting interconnection with Yokogawa CENTUM VP DCS, ProSafe RS safety systems, and third-party SCADA (such as Schneider and Siemens systems);

High reliability design: Key components (CPU, power supply, communication bus) support redundant configuration, module hot plugging, wide temperature environment adaptation (-20~+70 ℃ optional), meeting the uninterrupted operation requirements of industrial sites.

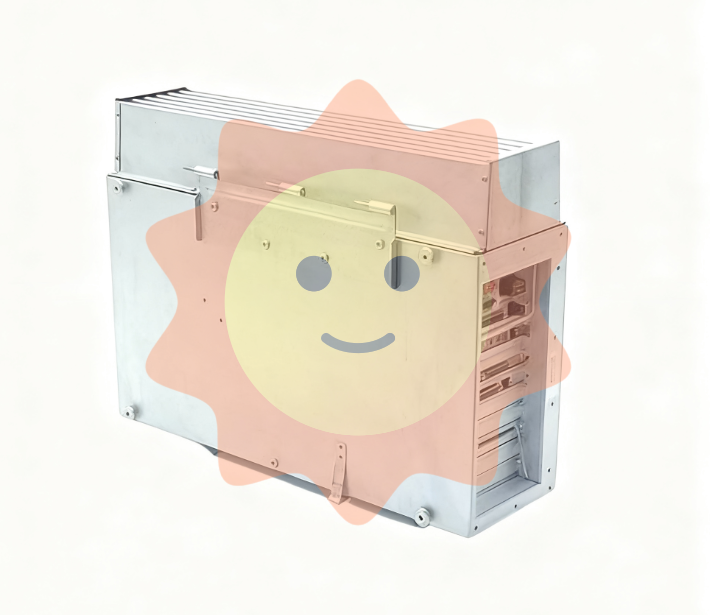

Expansion unit: Connected to the control unit through the E2 bus, each control unit can expand up to 8 expansion units, supporting mixed base configuration (long+short) to achieve flexible expansion of I/O points;

Redundant configuration: CPU, power supply, E2 bus, and Ethernet can all be redundant, with a redundancy switching time of less than 100ms to ensure seamless switching in case of faults.

2. Typical System Topology Example

plaintext

[Upper System] ← Ethernet (Modbus TCP) → [FCN-500 Control Unit (Redundant CPU+Power Supply)]

↓ (E2 bus)

[Extension Unit 1 (AI/AO module)] ←→ [On site sensors/actuators]

↓

[Expansion Unit 2 (DI/DO Module)] ←→ [Valve/Pump Control Circuit]

↓

[Expansion Unit 3 (Fieldbus Module)] ←→ [HART/Fieldbus Smart Devices]

Engineering development and operation characteristics

1. Programming and configuration tools

FCN-500 comes with Yokogawa Engineering Tool Kit, supporting IEC 61131-3 standard programming language to reduce development difficulty:

Logic Designer: a control program development tool that supports five languages: FBD (Function Block Diagram), LD (Ladder Diagram), ST (Structured Text), SFC (Sequential Function Diagram), and IL (Instruction List). It provides drag and drop programming and template libraries (such as PID control blocks and flow calculation blocks);

Resource Configurator: a hardware configuration tool that maps logical I/O to physical modules, supports IP address and communication protocol parameter settings, and does not require manual driver writing;

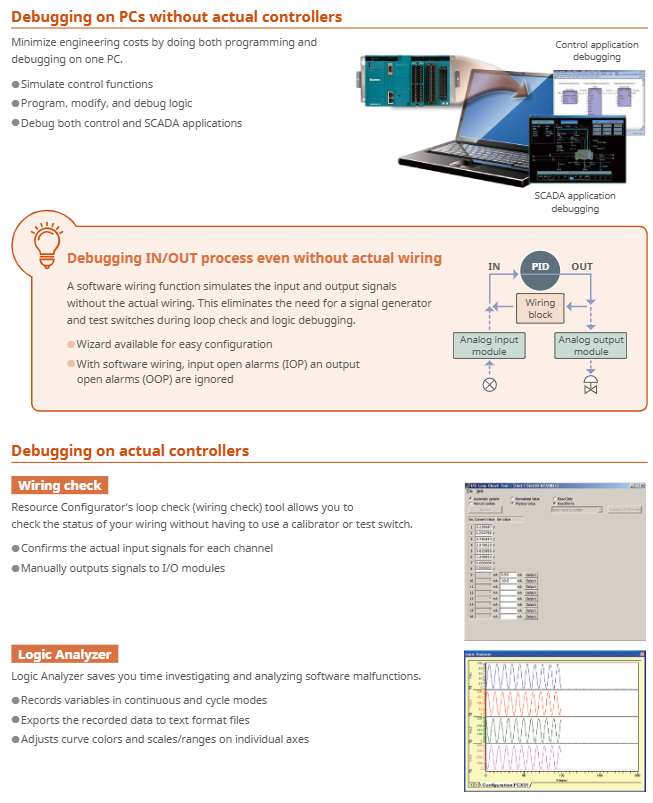

Simulator function: Supports hardware free debugging, can simulate control logic and I/O signals on a PC, and shorten the on-site debugging cycle.

2. Operations and diagnostic capabilities

Module hot plugging: All I/O modules and power modules support online replacement, and the configuration is automatically loaded after replacement without the need for system shutdown;

Status monitoring: The CPU module comes with an LCD display screen and LED indicator lights, which display the system status (running/faulty) and I/O module health in real time; Support exporting logs (fault records, operation records) through SD card without the need to connect to a PC;

Remote operation and maintenance: Remote diagnosis can be achieved through Web HMI or Yokogawa PRM (Plant Resource Manager) system, supporting I/O channel fault location, module firmware online upgrade, and reducing on-site maintenance costs.

Key modules and selection information

1. Core module model and function

Module Type Model Example Core Functions

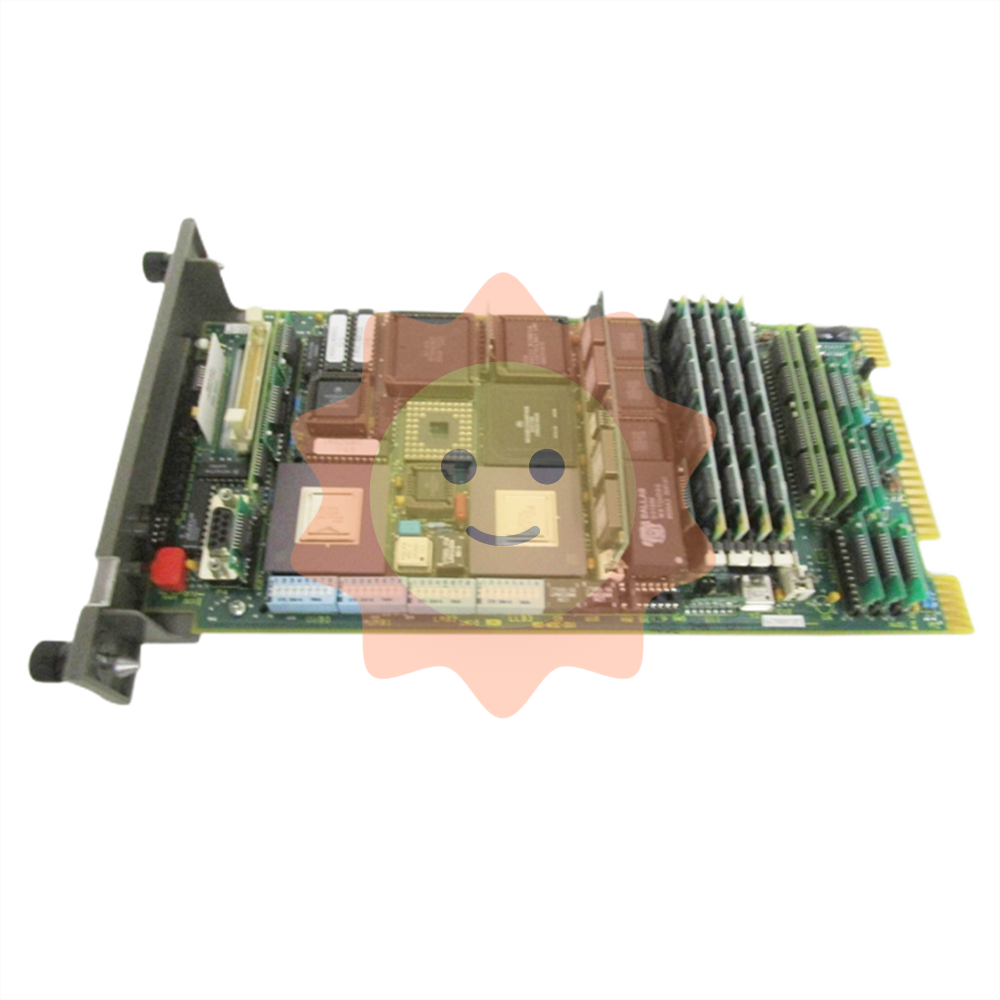

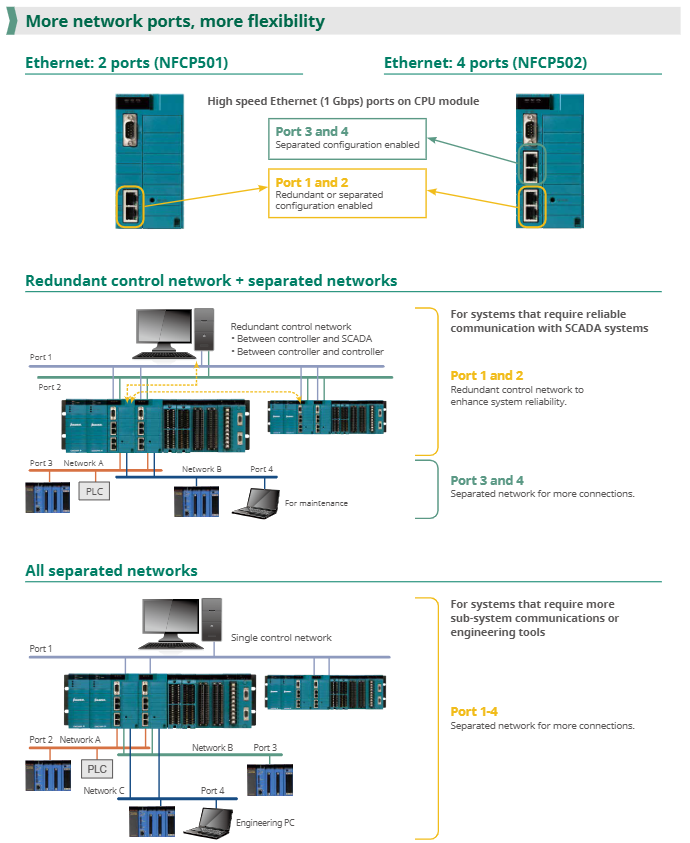

CPU module NFCP501 (2 Ethernet ports) with 2 Gigabit Ethernet channels, supporting Modbus/DNP3 protocols, with optional single/redundant configurations

NFCP502 (4 Ethernet ports) 4 Gigabit Ethernet channels, supporting independent network partitioning (such as control network+operation and maintenance network)

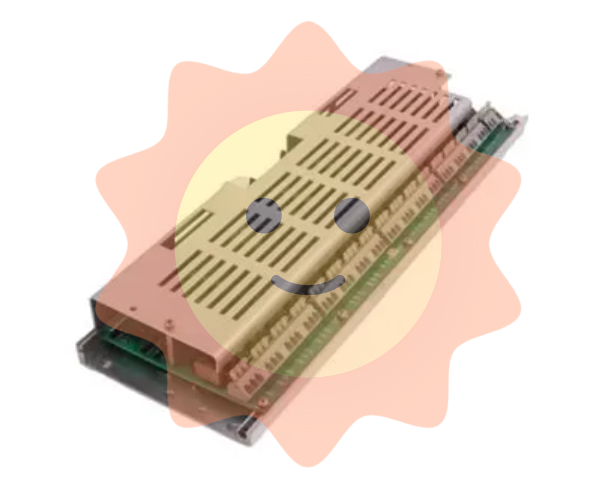

Power module NFPW441 (100-120V AC) system power supply (5.1V DC)+on-site power supply (24V DC), supports redundancy

NFPW444 (24V DC) DC input power supply, suitable for industrial 24V DC bus power supply scenarios

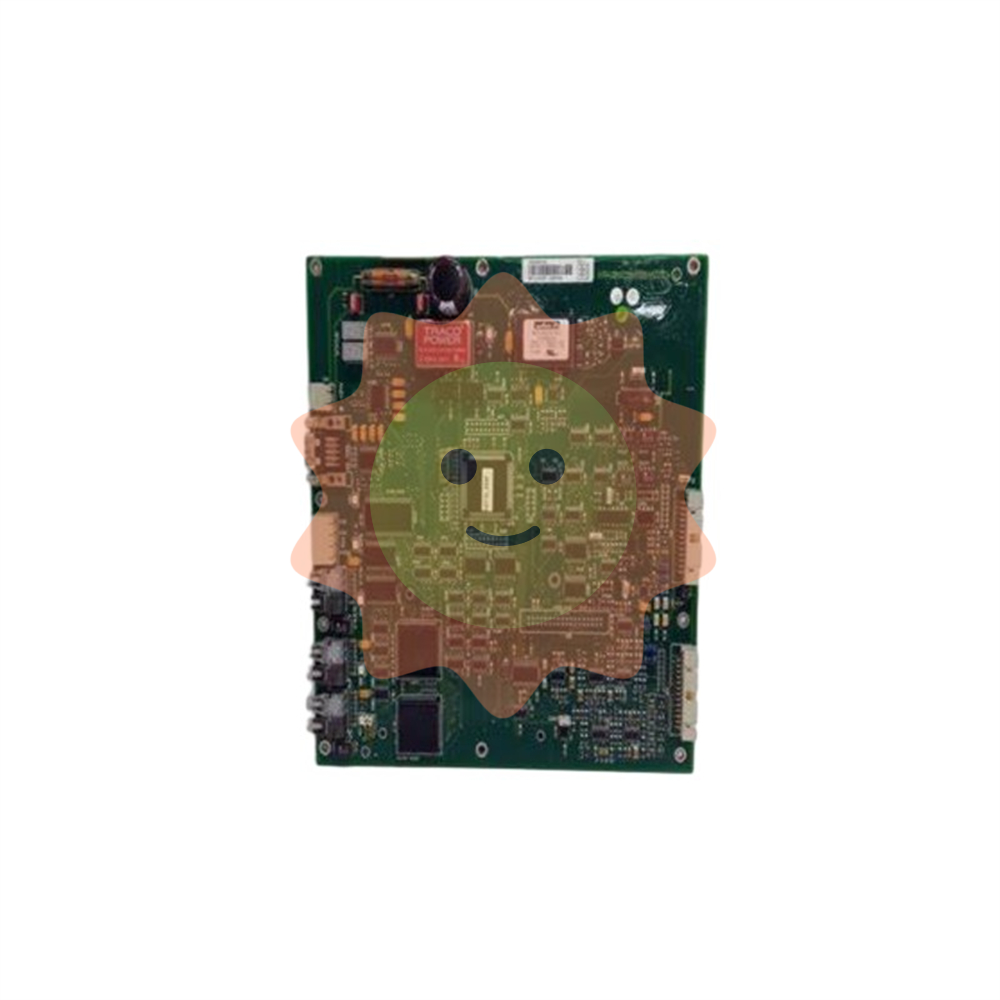

Analog input module NFAI135 (8 channels) 4-20mA input, channel isolation, accuracy ± 0.1% FS, supports HART protocol

NFAR181 (12 channel) RTD input (platinum resistance 100 Ω/1000 Ω), supports wire breakage detection

Digital output module NFDV551 (32 channels) 24V DC output, channel isolation, supports fail safe output (Fallback)

NFDR541 (16 channel) relay output (24-125V DC/100-240V AC), suitable for high-power loads (such as motor contactors)

Communication module NFLF111 (4-port) FOUNDATION Fieldbus communication, supporting 16 devices per port

NFLP121 (1 port) PROFIBUS-DP master station, supporting 123 slave devices

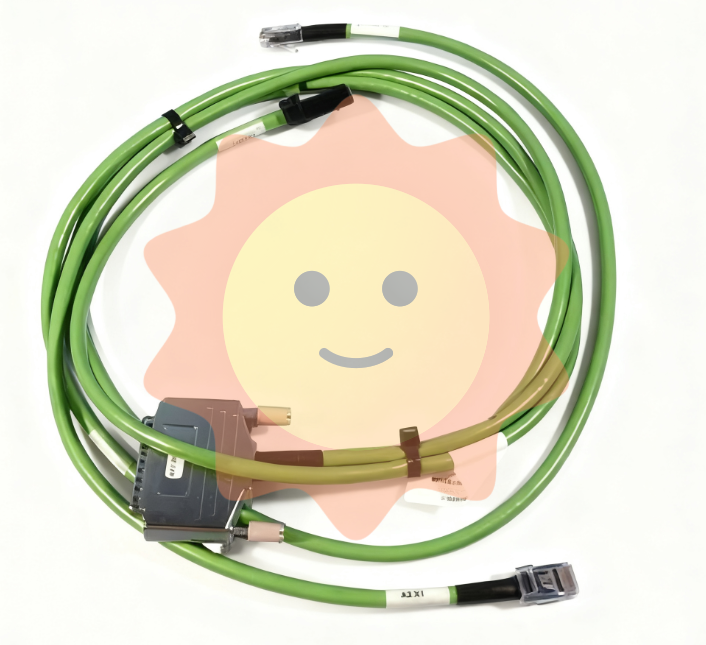

Expansion bus module N2EB100 E2 bus interface module, realizing the connection between control unit and expansion unit, supporting redundancy

2. Key dimensions for selection

Control scale: Select the base type (long/short/compact) and the number of expansion units based on the number of I/O points. A single system can support up to 79 I/O modules;

Environmental requirements: Standard temperature modules (0-55 ℃) are selected for conventional environments, wide temperature models (-20~+70 ℃) are selected for low/high temperature scenarios, and G3 coating is optional for corrosive environments;

Communication protocol: Select the communication module based on the type of on-site equipment (such as selecting NFAI135 AI module for HART devices and NFLF111 module for Fieldbus devices);

Reliability requirements: For critical scenarios (such as chemical reaction control), CPU, power supply, and E2 bus redundancy should be configured. For non critical scenarios (such as regular monitoring), menu configuration is available.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

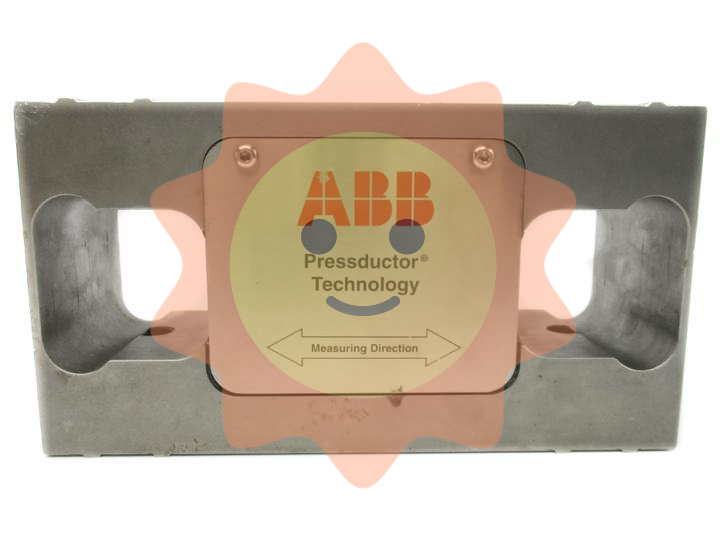

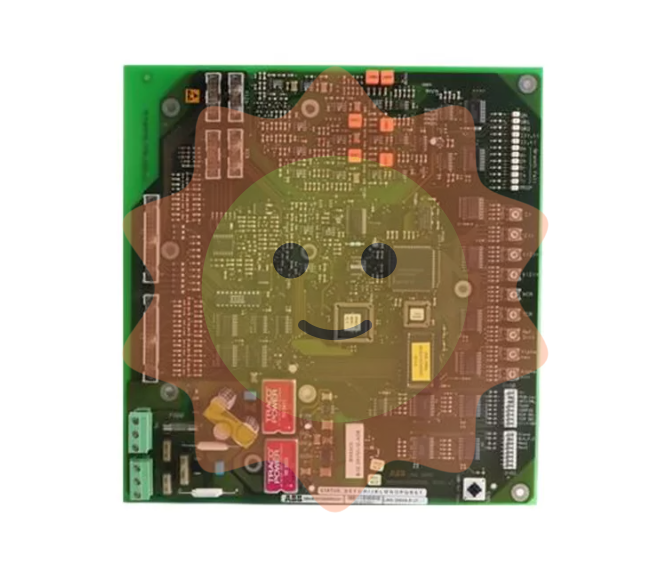

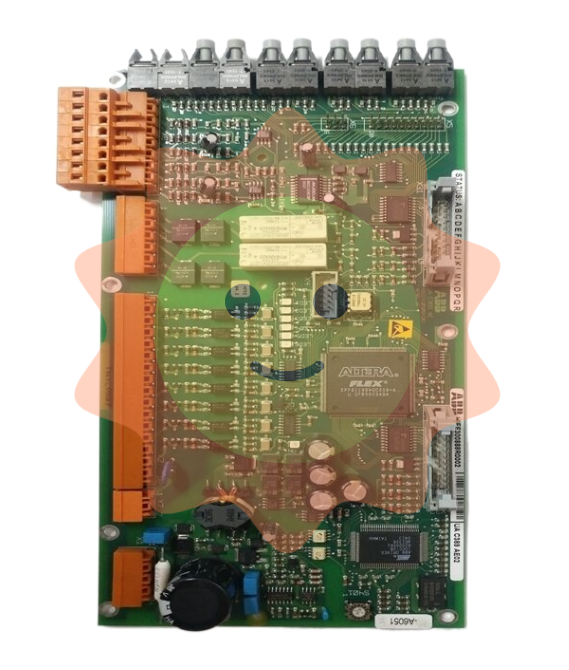

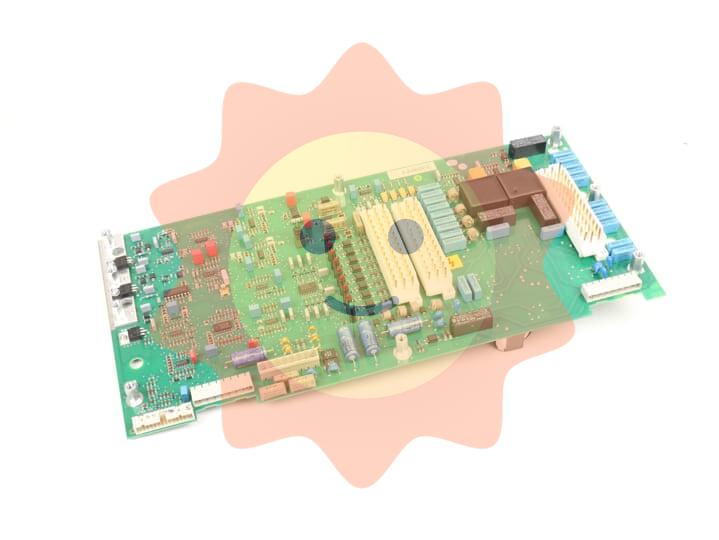

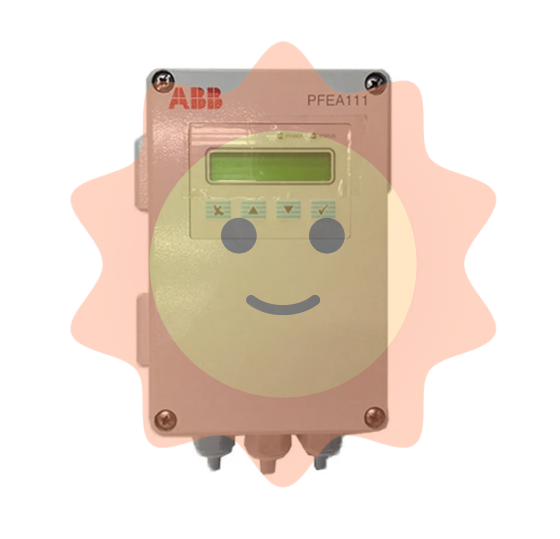

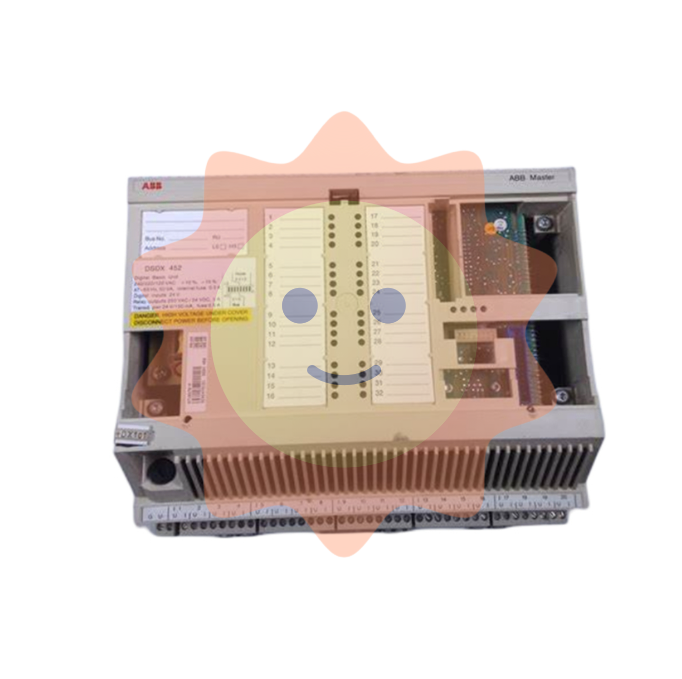

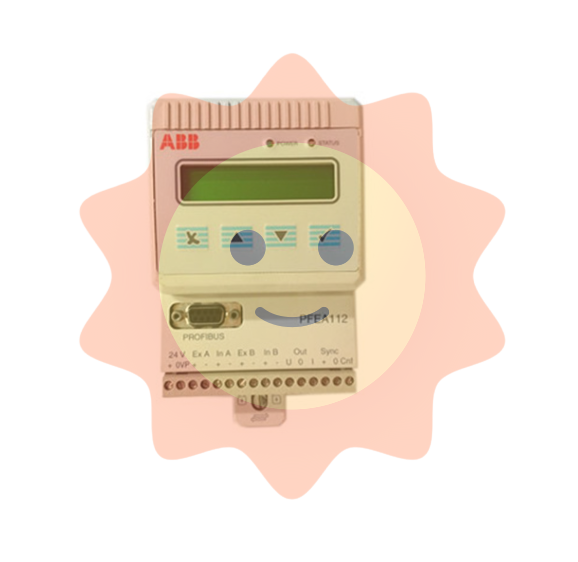

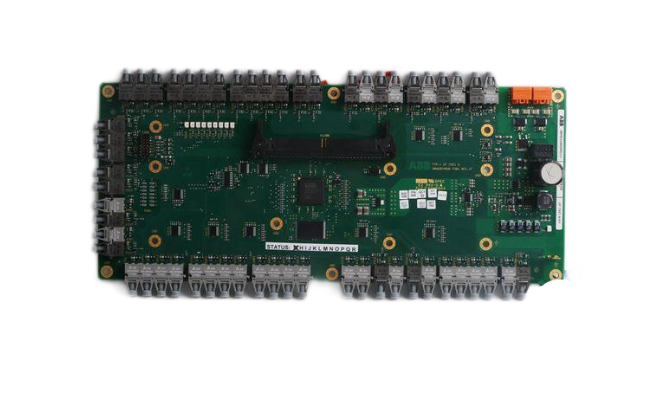

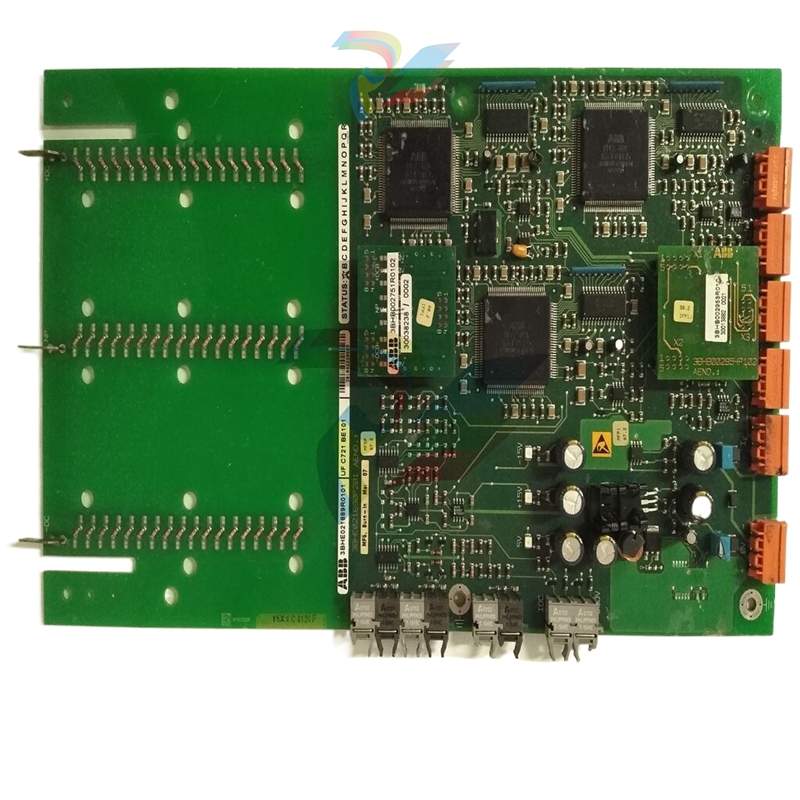

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

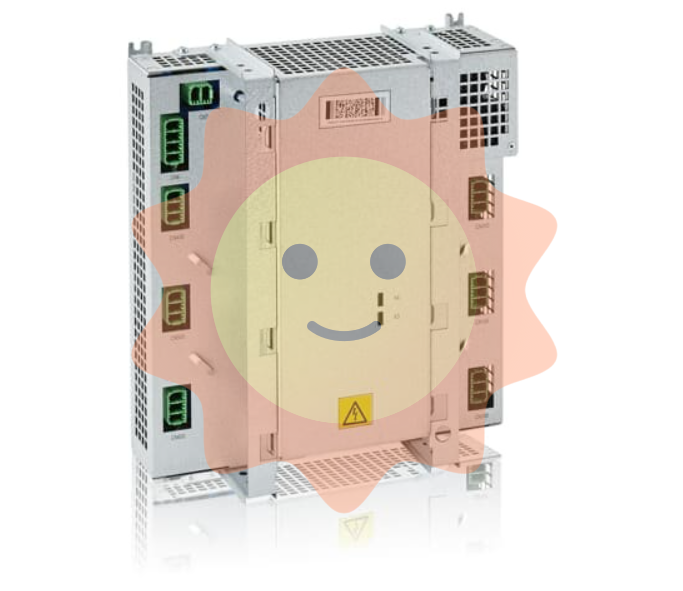

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com