Honeywell FS10 Fire Detection Systems For Liquid Paint Spray and Electrostatic Powder Coating

Honeywell FS10 Fire Detection Systems For Liquid Paint Spray and Electrostatic Powder Coating

Product Overview

Fire Sentry FS System 10 ™ FS10-R is a fire detection/process control system designed specifically for automatic electrostatic powder spraying booth, belonging to multispectral digital photoelectric infrared fire detectors. It protects electrostatic powder spray booths worldwide, achieving millions of hours of safe operation and ensuring process safety 24/7.

Core Features

Multispectral detection: Using multispectral digital optoelectronic infrared technology, it has the ability to detect visible light, near-infrared, and wideband infrared.

Two level response mechanism: Unique two-level ALERT (warning) and FIRE ALARM (fire alarm) response, issuing a warning for gun "fireball" type fires first, and if the fire persists, issuing a fire alarm within 4-5 seconds.

Anti interference ability: not affected by false alarms caused by arc or corona discharge, insensitive to background radiation energy such as paint heaters, not affected by smoke absorption or paint solvent mist in liquid paint spraying booth, able to detect paint, powder or oil residue through the detector lens.

Intelligent function: Built in automatic "through the lens" self-test function, equipped with RS-485 interface for digital communication, FirePic ™ Retrievable pre fire data records, SnapShot ™ It can dynamically display the content detected by the detector in graphics.

Application scenario (indoor use only)

Liquid paint spraying line

Aerosol filling

Powder coating booth

Curing Oven

Product Details

Fire Sentry FS System 10 ™

Design purpose: Designed specifically for liquid and powder coating applications, it is a high-speed detection solution with process control capabilities. It can quickly detect flames, initiate the shutdown of the electrostatic coating process within milliseconds, and prevent the spread of fire.

Controller configuration: There are two configurations: wall mounted controller and card type controller. The wall mounted controller is an independent system installed in a NEMA 12 enclosure with an LCD display and LED status lights, and includes three 10 ampere mechanical relays for turning off paint flow, static electricity, and conveyor belts.

Data storage and communication: The detector reports real-time event history and fire technology data, stored in the non-volatile memory of the controller, FirePic ™ And SnapShot ™ Data can be downloaded from the RS-232 port of the controller via a PC, and each controller can be connected to 1 or 2 detectors.

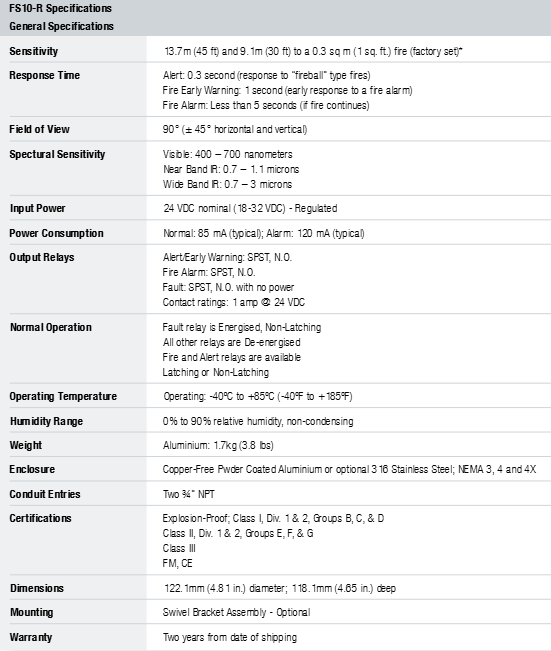

Fire Sentry FS10-R Unitised

Design Basis: Based on Fire Sentry FS System 10 ™ Design with independent operational capability.

Performance features: Its WideBand IR ™、 Near band IR and visible light sensors combined with advanced signal processing provide optimal performance, high-speed fire response, and optional factory sensitivity settings and alarm outputs, providing an enhanced fire detection and safety solution for the coating industry.

Interface method: Designed to be used in conjunction with any approved fire alarm panel, the interface with the fire alarm panel is achieved through ALARM, ALERT, and FAULT relays of the detector.

Technical specifications

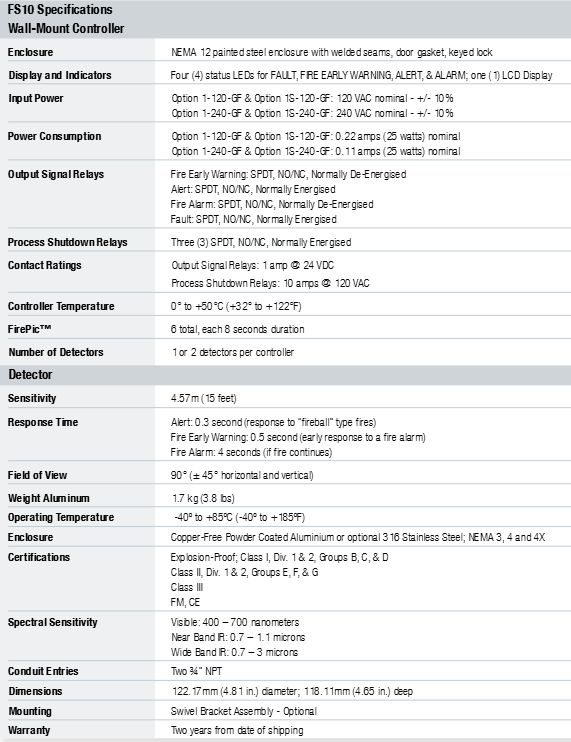

FS10 wall mounted controller specifications

Shell: NEMA 12 painted steel shell with welded seams, door gasket, key lock.

Display and indicator: 4 status LEDs (fault, fire early warning, warning, alarm), 1 LCD display screen.

Input power supply: There are different options such as 120VAC and 240VAC, allowing for ± 10% fluctuation.

Power consumption: The 120VAC option is rated at 0.22 amperes (25 watts), while the 240VAC option is rated at 0.11 amperes (25 watts).

Output signal relay: including fire early warning, warning, fire alarm, fault and other relays, with a rated contact value of 1 ampere at 24VDC.

Process shutdown relays: 3 SPDT relays with contact ratings of 10 amperes at 120VAC.

Controller temperature: 0 ° to+50 ° C (+32 ° to+122 ° F).

FirePic ™: There are a total of 6, each lasting 8 seconds.

Detector (FS10 related) specifications

Sensitivity: 4.57 meters (15 feet).

Response time: 0.3 seconds for warning (for "fireball" type fires), 0.5 seconds for early warning of fires, and 4 seconds for fire alarm (if the fire persists).

Field of view: 90 ° (horizontal and vertical ± 45 °).

Weight (aluminum): 1.7 kilograms (3.8 pounds).

Working temperature: -40 º to+85 º C (-40 º to+185 º F).

Shell: Copper free powder coated aluminum or optional 316 stainless steel, compliant with NEMA 3, 4, and 4X standards.

Certification: Explosion proof; Class I, Zone 1 and Zone 2, Groups B, C, and D; Class II, Zone 1 and Zone 2, Groups E, F, and G; Class III; FM and CE certification.

Spectral sensitivity: visible light 400-700 nanometers, near band IR 0.7-1.1 micrometers, wide band IR 0.7-3 micrometers.

Conduit inlet: Two three-quarters "NPTs.

Dimensions: Diameter 122.17 millimeters (4.81 inches), depth 118.11 millimeters (4.65 inches).

Installation: Optional rotating bracket component.

Warranty: Two years from the date of shipment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands