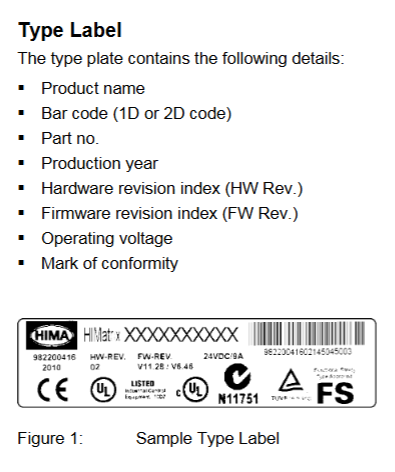

HIMA HIMatrix F2 DO 8 01 Remote I/O Module

ESD protection: Only personnel with knowledge of electrostatic protection are allowed to operate. ESD wristbands should be worn during work, and when idle, they should be stored in anti-static packaging to avoid static electricity damaging the internal circuits of the module.

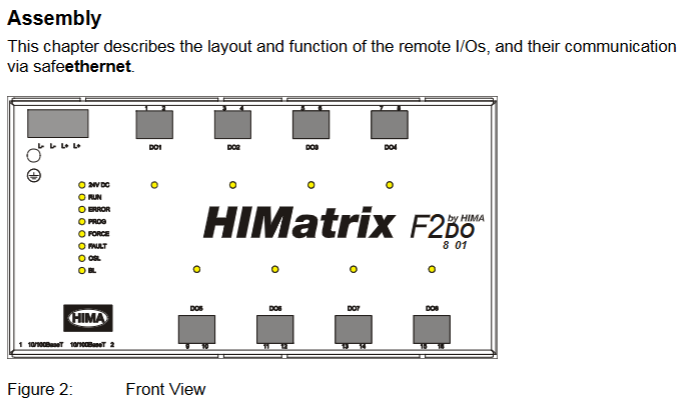

Yellow light (Initiat/STOP/RUN): Constant light indicates corresponding status, slow flashing indicates loading configuration or forced function activation;

Communication light (green/yellow next to RJ-45): Green light constantly on indicates full duplex, flashing indicates conflict; A constant yellow light indicates a normal physical connection, while a flashing light indicates data transmission;

I/O light (DO 1-8, yellow): normally on indicates that the output is powered on (relay is engaged), and off indicates that the output is powered off (safe state).

Reset button function

Reserved reset hole in the upper left corner of the module (triggered by an insulating pin), only used for scenarios where the administrator account is forgotten or the IP address does not match: When restarting, press and hold the reset button for ≥ 20 seconds to restore the default parameters (IP: 192.168.0.99; SRS: 60000.200.0 (SILworX)/60000.0.0 (ELOP II Factory)), and clear the user account (only the default administrator account is retained, password is empty).

Installation and configuration process

(1) Module installation and wiring

Installation prerequisites

It needs to be fixed on a 35 mm DIN rail with reserved heat dissipation space around it (high power dissipation, avoid being adjacent to heating equipment);

Ex Zone 2 installation requires additional requirements: enclosure protection level ≥ IP54 (compliant with EN 60529), enclosure must be labeled with a "power off operation only" warning, equipped with a 10A delay fuse, PELV/SELV power supply, and reference to EN 60079-15 standard (terminal wiring, creepage distance, etc.).

Wiring specifications

Power wiring: Connect the positive terminal of the 24 VDC module to the "+" terminal and the negative terminal to the "-" terminal. It needs to be powered independently to avoid being in line with the power circuit;

Relay output wiring: Each output corresponds to 2 terminals (such as DO1 corresponding to terminal 1/2, A/B contacts), which are normally open contacts. The load needs to be equipped with external fuses according to the voltage type (DC loads require additional anti reverse protection);

Communication wiring: The RJ-45 interface is connected to a SafeEthernet network, supporting daisy chain topology, and requires the use of CAT 5e or higher shielded cables (shielded layer single ended grounding to reduce interference).

(2) Software configuration configuration

SILworX configuration (version ≥ 7)

Core Parameters (Module tab):

Basic parameters: Configure module name, IP address, subnet mask (default 192.168.0.99), SRS (system rack slot address, default 60000.200.0);

Fault monitoring: Enable MOT/FTT testing, configure temperature threshold (output cut-off in case of overheating), read fault codes (e.g. 0x0001 indicates module fault, 0x0400 indicates first level overheating).

Channel configuration (DO 8: Channels tab): Assign global variables to each output (DO1-DO8), set output values (1=power on, 0=power off), and monitor single channel faults (such as 0x10 indicating relay 1 feedback error).

ELOP II Factory configuration (version<7)

Assign system signals to output channels through the "Signal Editor", with configuration parameters similar to SILworX. The core difference lies in the signal mapping method (based on "signal name channel" association rather than variable allocation), and the fault code is consistent with the state definition (such as Mod. Error Code 0x0010 indicating configuration error).

Operation, maintenance, and troubleshooting

(1) Daily operation and diagnosis

operation monitoring

Real time status can be viewed through LED: the RUN light is always on to indicate normal operation, the ERROR light is on to indicate a fault, and the I/O light corresponds to the output status;

Detailed diagnosis: Read fault logs (such as relay adhesion, communication interruption) through programming tools, support online viewing of output feedback values (ensure that instructions are consistent with actual status).

Common faults and solutions

|Fault phenomenon | Possible causes | Troubleshooting steps|

|All outputs are unresponsive (all I/O lights are off) | 1 The module has not entered the RUN state; 2. Power supply failure; 3. Communication interruption | 1 Check the system light (whether it is in RUN state); 2. Measure 24 VDC power supply; 3. Check the Ethernet light (whether there is a physical connection)|

|Single output fault (ERROR light on, fault code 0x10) | 1. Relay 1 feedback error; 2. Contact adhesion | 1 Power off and restart module; 2. Check the load circuit (whether there is a short circuit); 3. Module replacement verification|

|Communication interruption (communication light off) | 1 IP address conflict; 2. Cable malfunction; 3. Controller offline | 1 Check if the module IP and PADT are on the same network segment; 2. Replace the communication cable; 3. Confirm whether the controller is operating normally|

(2) Maintenance and Lifecycle Management

regular maintenance

Operating system update: Utilize system downtime to load the latest version of the operating system through programming tools (modules must be in STOP state), and backup configuration before updating to avoid data loss;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands