GE Qualitrol IC670ALG230 Analog Input Module

GE Qualitrol IC670ALG230 Analog Input Module

Product core positioning and application scenarios

IC670ALG230 is a current source analog input module launched by Qualitrol (now under GE). Its core function is to accurately convert the current signals (0-20 mA or 4-20 mA) output by 2-wire, 3-wire, or 4-wire sensors/transmitters in industrial fields into digital signals, which are transmitted to the GE field control system (with a bus interface unit BIU) to achieve real-time acquisition and monitoring of process parameters such as pressure, temperature, and flow rate. Its typical application scenarios cover industrial fields such as power, petrochemicals, and manufacturing, and are suitable for automation systems that require high accuracy of analog signals and centralized collection of multi-channel current signals.

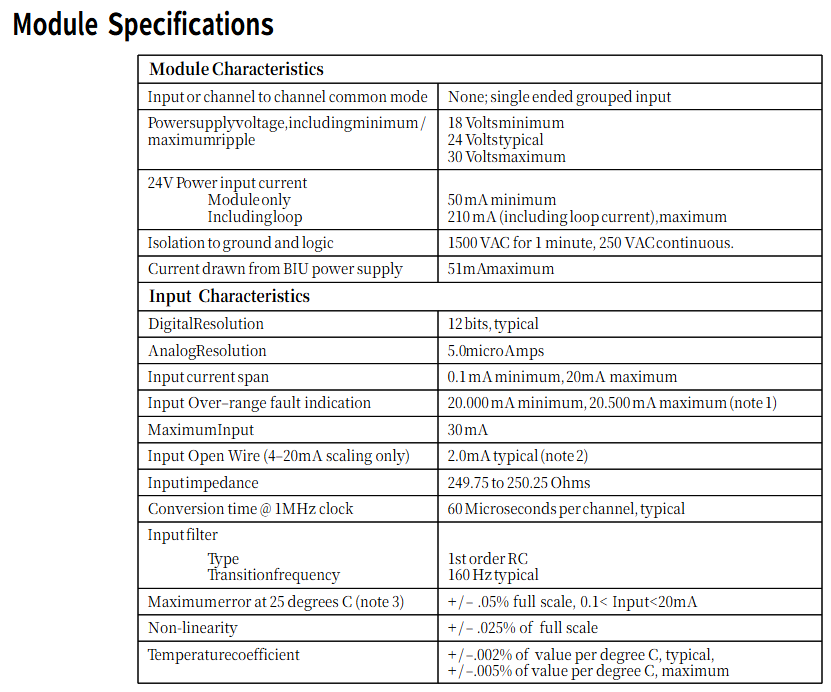

Core technical specifications

(1) Basic parameters of module

Category specific specification description

Channel configuration with 8 single ended grouped inputs (shared signal ground) and 8 inputs sharing the same 24 VDC power supply and signal common terminal, suitable for centralized collection of signals from similar sensors

Software configurable input signal range: 0-20 mA (default), 4-20 mA supports industrial standard current signals, 4-20 mA mode can detect wire breakage faults (input<2.0 mA triggers diagnosis)

Power supply requirement: Power supply voltage: 18-30 VDC (typical 24 VDC); Module power consumption: 50 mA (module only), 210 mA (including loop current) can share 24 VDC power supply with bus interface unit (BIU), please note that the total current load does not exceed the limit value

Isolation performance for ground and logic isolation: 1500 VAC (1-minute withstand), 250 VAC (continuous withstand), high isolation level to suppress industrial field grounding loops and electromagnetic interference (EMI), protect modules and backend systems

(2) Signal Conversion and Accuracy

Category specific specifications Technical advantages

Resolution: Digital resolution of 12 bits, analog resolution of 5.0 μ A, high-precision conversion ensures that small current changes can be recognized (such as a minimum resolution of 4 μ A changes under 4-20 mA signals)

Conversion speed of approximately 60 μ s per channel (1 MHz clock). Fast conversion supports high-frequency data acquisition and is suitable for dynamic process monitoring (such as rapidly changing pressure signals)

Measurement accuracy at 25 ℃ ± 0.05% full range (0.1-20 mA input), non-linear error ± 0.025% full range high precision meets industrial level process control requirements, reducing the impact of signal acquisition errors on control logic

Typical temperature coefficient is ± 0.002%/℃, with a maximum of ± 0.005%/℃. Within a wide temperature range (commonly seen in industrial sites -10-60 ℃), the accuracy attenuation is small, making it suitable for complex environments

(3) Input protection and anti-interference

Overcurrent protection: maximum input current of 30 mA, built-in 1 A fuse (24V output circuit) to prevent overcurrent damage caused by sensor failure;

Overvoltage protection: 30 V MOV (metal oxide varistor) to suppress voltage spikes on the power supply side;

Filter design: A first-order RC filter with 250 Ω resistor and 0.1 μ F capacitor connected in series for each channel, with a transition frequency of approximately 160 Hz, to filter out high-frequency noise;

Wire breakage detection: Only 4-20 mA mode is supported. When the input current is less than 2.0 mA, the BIU triggers wire breakage diagnosis for timely troubleshooting of sensor faults.

Hardware Design and Working Principle

(1) Internal circuit structure

The core circuit of the module revolves around "current voltage conversion+signal conditioning+A/D conversion", and the key path is as follows:

Signal input: After the current signal of the on-site sensor is connected to the channel, it first passes through a 250 Ω precision resistor to convert the current signal into a voltage signal (such as 20 mA corresponding to 5 V voltage);

Filtering and buffering: After the RC filter filters out high-frequency noise, the signal is buffered by an operational amplifier (OPAMP) to avoid load effects affecting measurement accuracy;

A/D conversion: A 12 bit A/D converter converts analog voltage into digital signal, and the conversion result is temporarily stored in an 8-word (16 byte) data buffer inside the module;

Data transmission: Unscaled digital data is transmitted to the host or local processor through a bus interface unit (BIU), and the BIU performs engineering unit scaling (such as mapping 4-20 mA to 0-100 ℃).

(2) Status indication and wiring

LED indicator light: The transparent area at the top of the module is equipped with an LED, which lights up under the conditions of "backplane power supply+normal on-site power supply+fuse not blown" to visually determine the power supply status of the module;

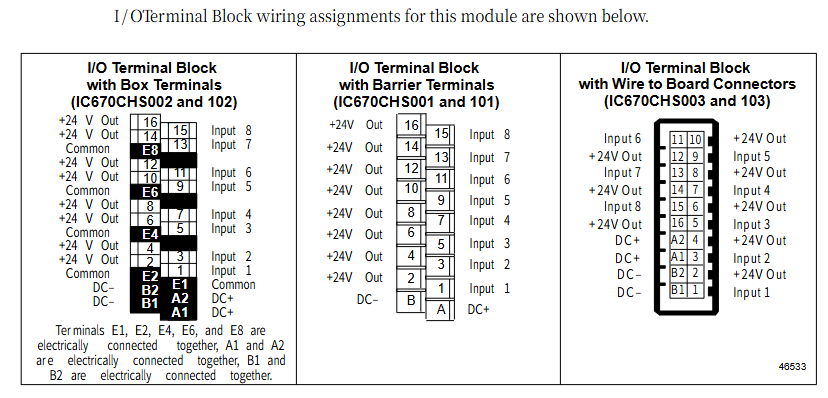

Terminal layout: Using standardized I/O terminal blocks (supporting box type terminals IC670CHS002/102, fence type terminals IC670CHS001/101, and wire to board connectors IC670CHS003/103), the key terminals include:

+24 V Out ": 8 channels of shared 24 V output (with fuses), providing loop power for 2-wire transmitters;

Input 1-8 ": 8-channel current signal input terminal;

DC - "/" Common ": The signal common terminal needs to be connected to the sensor signal ground to avoid grounding loops;

Chassis Ground ": The module casing ground needs to be short circuited to the control cabinet casing to enhance anti-interference capability.

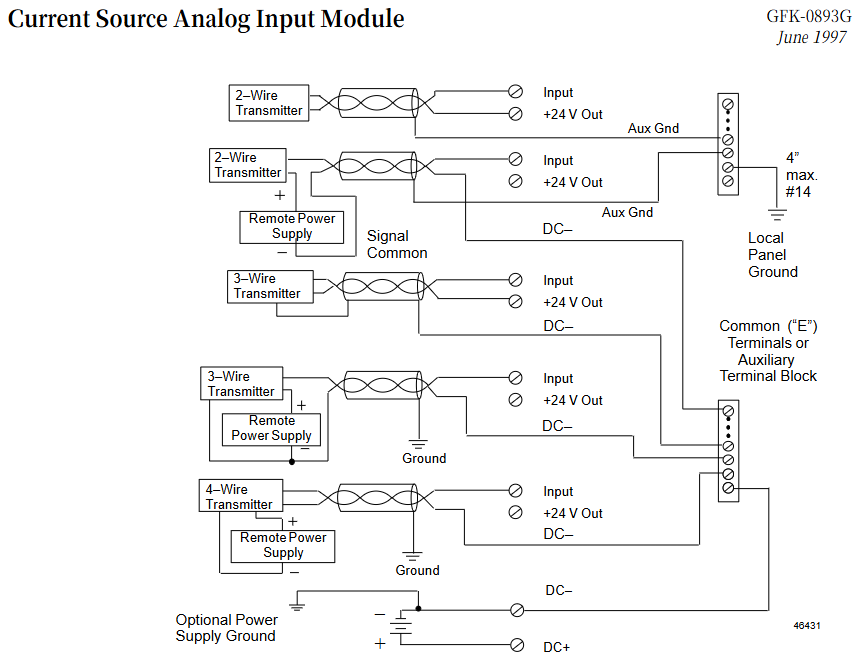

On site wiring and sensor adaptation

The module supports 2-wire, 3-wire, and 4-wire sensors/transmitters, and the wiring method needs to be selected according to the sensor type. The key configurations are as follows:

(1) 2-wire transmitter (loop power supply)

Wiring characteristics: The sensor power supply and signal share two wires. The module "+24 V Out" provides circuit power, "Input" receives current signals, and "DC -" is the common terminal;

Attention: AWG # 14- # 22 (cross-sectional area 0.36-2.1 mm ²) should be used as the wire, and the recommended maximum wiring distance should not exceed 100 meters (to avoid voltage drop causing insufficient sensor power supply); The shielding layer needs to be grounded separately and not shared with the power supply ground.

(2) 3-wire transmitter (independent power supply+signal)

Wiring characteristics: The sensor requires separate power supply (module "+24 V Out" or external power supply can be used), the signal terminal "+" is connected to module "Input", "-" is connected to "DC -", and the power supply "-" and signal "-" are grounded together;

Adaptation scenario: For sensors that require higher power supply voltage or current (such as some high-precision temperature transmitters), it is recommended to use an auxiliary terminal block to consolidate the common terminal and simplify wiring.

(3) 4-wire transmitter (completely isolated)

Wiring characteristics: The sensor power supply is completely isolated from the signal (independent external power supply), the signal "+" is connected to "Input", "-" is connected to "DC -", and the power ground and signal ground are separated to avoid ground loop interference;

Advantages: Suitable for long-distance (such as over 200 meters) or strong interference scenarios (such as near frequency converters), isolation design improves signal stability.

(4) Wiring specifications

Wire selection: It is recommended to use shielded twisted pair for analog signals, with the shielding layer grounded at one end (preferably on the module side);

Grounding requirements: Only ground the signal common terminal on the module side to avoid multiple grounding points forming a ground loop; The module 'Chassis Ground' needs to be connected to the control cabinet casing with a short wire (recommended<4 inches, # 14 wire);

Auxiliary terminal block: When using fence type terminals or wire to board connectors, auxiliary terminal blocks (such as IC670CHS series) should be used to expand the wiring terminals. All terminals inside the auxiliary terminal block are connected and can be used to summarize the common terminal or power terminal.

Software Configuration and Data Processing

(1) Parameter configuration

The module needs to be parameterized through a Bus Interface Unit (BIU) or host software, with the following key configuration items:

Input range: Each channel is independently configured with 0-20 mA or 4-20 mA, with a default range of 0-20 mA;

Engineering unit scaling: defined by BIU as "Engineering Lower Limit (Eng Lo) - Engineering Upper Limit (Eng Hi)" and "Integer Lower Limit (Int Lo) - Integer Upper Limit (Int Hi)", default scaling is Eng Lo=0, Eng Hi=20000 (corresponding to 0-20 mA), Int Lo=0, Int Hi=20000;

Diagnostic enablement: Enable disconnection diagnosis (triggered by input<2.0 mA) and over range diagnosis (triggered by input>20.5 mA) in 4-20 mA mode.

(2) Data transmission

Data format: 8 inputs correspond to 8 16 bit digital quantities (unsigned integers), stored in the module data buffer, and periodically read by BIU (read cycle depends on system configuration, typically 10-100 ms);

Scaling logic: Taking the mapping of 4-20 mA to 0-100 ℃ as an example, BIU calculates the engineering value according to the following formula:

Engineering value=Eng Lo+Int Hi − Int Lo

Digital quantity - Int Lo × (Eng Hi - Eng Lo) (Example: When the digital quantity is 8000, the corresponding current is 8 mA, and the engineering value is 25 ℃).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com