GE IC693TCM302/303 Temperature Control Module

Control mode: Supports two operating modes: Open Loop and Closed Loop, suitable for different temperature control scenarios.

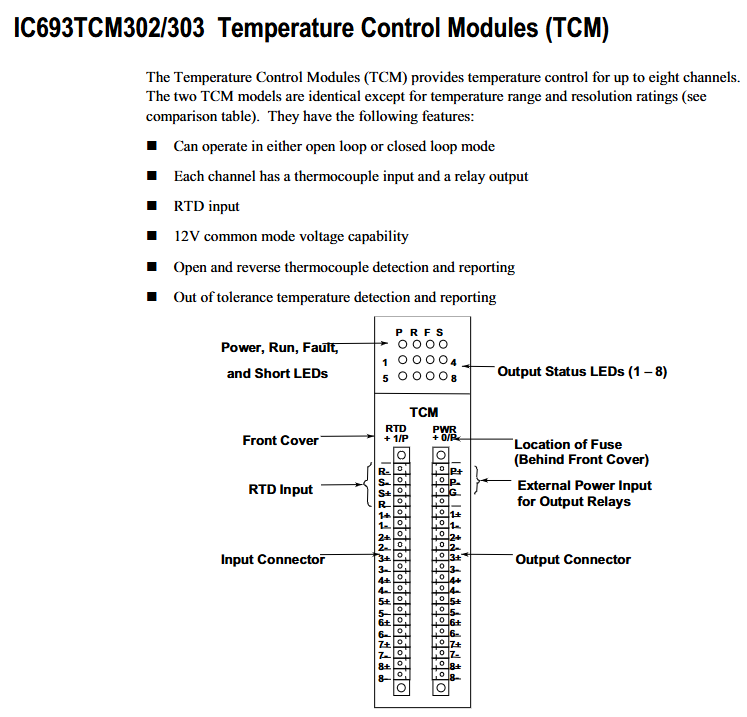

Channel configuration: It can achieve temperature control for up to 8 channels, each equipped with thermocouple input interface and relay output interface, and supports RTD (resistance temperature detector) input.

GE IC693TCM302/303 Temperature Control Module

Module core functions and general characteristics

The functional framework of the two TCM modules is consistent, with only differences in temperature range and resolution. The core capabilities include:

Control mode: Supports two operating modes: Open Loop and Closed Loop, suitable for different temperature control scenarios.

Channel configuration: It can achieve temperature control for up to 8 channels, each equipped with thermocouple input interface and relay output interface, and supports RTD (resistance temperature detector) input.

Voltage compatibility: Equipped with 12V common mode voltage capability, suitable for signal transmission needs in industrial scenarios.

Fault detection: supports automatic detection and reporting of two types of critical faults——

Thermocouple faults: including open circuit (Open) and reverse circuit (Reverse) faults;

Temperature anomaly: Detect and report temperature deviations that exceed the tolerance range.

Hardware Connection and Interface Description

The module is connected to external devices through two pairs of matching "plug-in connectors" with captive screw terminals for easy on-site wiring. The specific interface division is as follows:

Interface type, location, connection object, key terminal identification

Input connector module left thermocouple (8 channels, corresponding to 1+-1- to 8+-8- terminals), RTD (R+, R -, S+, S - terminals) - Channel input: 1+-1- to 8+-8- (each channel's positive and negative terminals correspond to a thermocouple)

-RTD inputs: R+, R -, S+, S - (compatible with RTD sensors)

Output connector module right side relay (8 channels, corresponding to 1+-1- to 8+-8- terminals), external power supply (P+, P - terminals) - channel output: 1+-1-~8+-8- (each channel positive and negative terminal corresponds to a relay)

-External power supply: P+(positive pole), P - (negative pole, supplying power to the output relay)

-Grounding: G terminal (grounding connection)

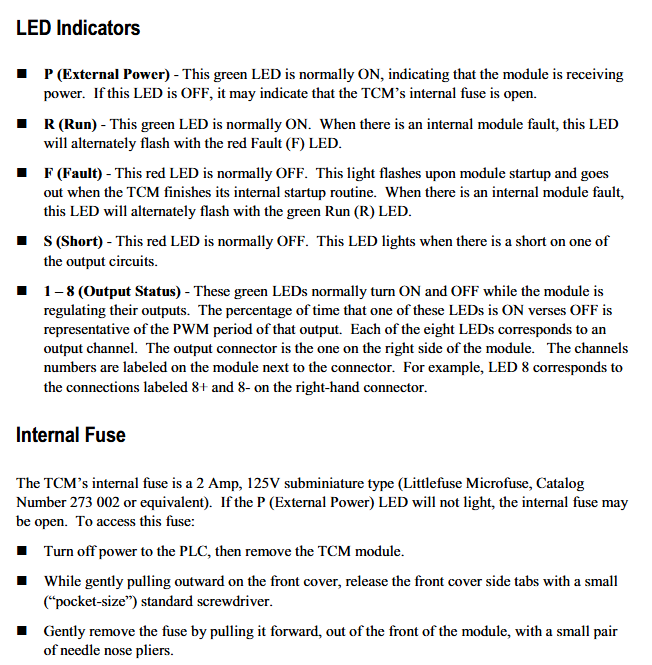

In addition, there is an internal fuse located behind the front cover of the module for circuit overload protection. The specific parameters are "2 Amp, 125V ultra small fuse" (recommended model: Littlefuse Microfiuse 273 002 or equivalent).

Meaning of LED status indicator light

The front of the module is equipped with 6 types of LED indicator lights, which provide feedback on device operation and fault information through on/off/flashing status. The specific instructions are as follows:

Meaning and Status Explanation of LED Identification Colors

P (External Power) green - normal state: constantly on, indicating that the module has been connected to an external power source;

-Abnormal state: Off, possibly due to a blown internal fuse.

R (Run) green - normal status: constantly on, indicating that the module is running normally;

-Abnormal state: The red F (Fault) LED flashes alternately, indicating an internal fault in the module.

F (Fault) red - normal state: normally off;

-Startup phase: flashing (module executing internal startup program);

-Abnormal state: The green R (Run) LED flashes alternately, indicating an internal fault in the module.

S (Short) red - normal state: normally off;

-Abnormal state: illuminated, indicating a short circuit fault in one of the output circuits.

1-8 (Output Status) Green - Function: Corresponding to 8 output channels, the indicator light on/off ratio reflects the PWM (Pulse Width Modulation) cycle of that channel;

-Example: LED 8 corresponds to the channel to which the 8+and 8- terminals of the right connector belong, and the on/off rhythm is synchronized with the channel output adjustment.

Automatic data exchange with PLC

The module and the CPU of Series 90-30 PLC achieve control and status feedback through "automatic data transmission", without the need for manual triggering. Each PLC sweep completes a data exchange, and the specific data flow is as follows:

1. PLC → TCM (Control Instruction Transmission)

PLC sends control instructions to TCM through% Q bit (digital output) and% AQ word (analog output), and the core instructions include:

Enable/Disable Output;

Control mode switching (Auto/Manual Mode);

Do Autotuning trigger;

Setpoint values transmission (target temperature);

Alarm Limit Values (temperature alarm upper and lower limits) transmission.

2. TCM → PLC (status information feedback)

TCM provides feedback on the operating status to PLC through the% I bit (digital input) and% AI word (analog input), with core information including:

Alarm status (such as over temperature alarm);

Output Short Circuit status;

Current Temperature (real-time temperature of each channel);

PWM period (the pulse period output by each channel);

TCM Error Code (locate specific fault type).

Core differences between TCM302 and TCM303

The two modules only differ in "temperature measurement range" and "resolution". TCM303 is the "extended range version", and the specific parameter comparison is as follows:

Comparison item IC693TCM302 IC693TCM303

J-type and L-type thermocouples have a temperature range of 0-450 ° C to 0-750 ° C

K-type thermocouple temperature range 0-600 ° C 0-1050 ° C

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands