KOLLMORGEN S200 High Performance Compact Brushless Servo Drive

3.5 Speed Loop

The maximum stable bandwidth can reach 800 Hz (when using SFD).

High command resolution, below 0.001 rpm when simulating commands.

The speed loop compensation parameters (KVP, KVI, ARF0, ARF1) are adjustable to adapt to different mechanical loads and resonance characteristics.

3.6 Command I/O

Provide rich interface options:

Simulated command input: differential range ± 12.5V, high signal-to-noise ratio, adjustable offset.

High speed input: can be used as a stepper command (up to 1.5 MHz) or PWM command (0.25 to 250 kHz).

Orthogonal input/output: RS-422/485 differential interface, maximum line frequency 625 kHz.

Universal input/output: Wide voltage range (± 4-30V), compatible with source and drain logic, fast response time.

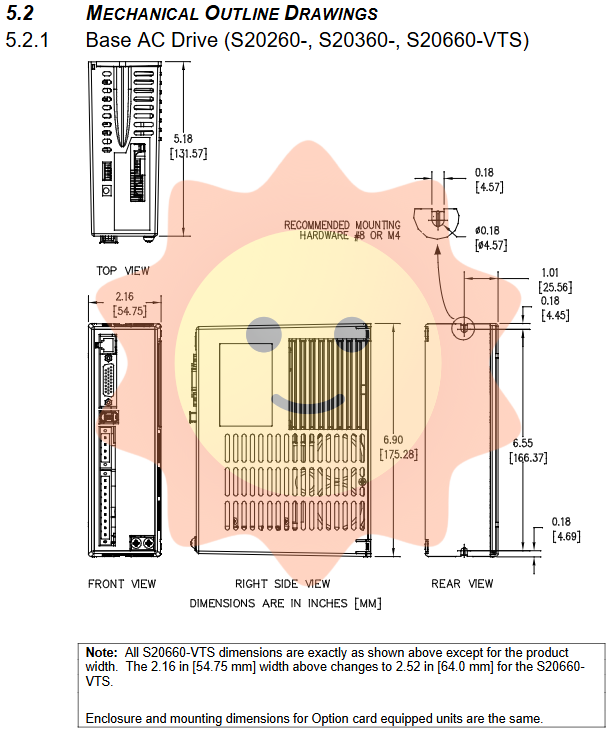

3.7 Machinery and Environment

The driver is designed for vertical installation inside the cabinet and needs to be installed on a flat, sturdy, and conductive grounding surface. The working temperature is 0-40 ° C (fully rated), and linear derating is required for 40-50 ° C. Storage temperature -35 to 85 ° C, humidity 10-90% non condensing.

3.9 Intelligent feedback device

SFD is one of the core advantages of the S200 system, providing extremely high position and velocity feedback quality.

Position signal: 24 bit resolution (0.0013 arcminutes per revolution), high repeatability, can further reduce noise through filtering.

Speed signal: resolution below 0.001 rpm, high update frequency, low noise.

Simulation encoder output: Multiple PPR values can be selected by rotating switch S1, with a maximum output line frequency of 2.5 MHz.

Installation and Configuration Guide

Quick Start

Follow different quick start guidelines based on the driver type (base unit or SynqNet version). The basic steps include software installation, hardware setup, communication wizard configuration, motor feedback configuration, and parameter saving.

S200 basic unit driver configuration:

Hardware connection: Use a serial communication cable (to be ordered separately) to connect the J5 port of the driver to the host computer.

Software configuration: Run the S200 Tools software, select the "Serial" mode through the communication wizard, and test the connection.

Feedback configuration: The basic unit only supports SFD motor feedback connected through J3. If using SinCos or ComCoder, J14 port must be used (only for models with tabs).

Parameter saving: Distinguish between "Download NV" (saved to permanent storage) and "Download Drive" (saved to temporary RAM). It is recommended to use the latter for testing, and after confirmation, use the former for permanent saving.

S200 SynqNet driver configuration:

Prerequisite: Install Motion Developer's Kit and SynqNet controller.

Network connection: Use Ethernet cables to daisy chain the J11 (IN) and J12 (OUT) ports of the SynqNet controller and each driver.

Software configuration: Select the "SynqNet" mode in S200 Tools, and the software will automatically discover nodes on the network.

Feedback source selection: In the SynqNet options tab, select "Base Unit Feedback" or "Option Card Feedback" based on the actual port (J3 or J14) connected to the feedback device.

Advanced feedback configuration: For SinCos or ComCoder, it is necessary to manually calculate and set parameters such as KIP, 2TFO, 2ITTriP to match motor characteristics.

Switch settings and basic configuration

The switches S1 and S2 on the top of the drive are used for quick basic configuration.

S2 DIP switch: Position 1 selects torque/current or speed control mode, position 2 selects SFD or 6-step (Hall) feedback type. Factory default enable switch setting.

S1 rotary switch (for SFD feedback): Set the number of lines output by the simulation encoder (such as 50010242048, etc.).

S1 rotary switch (for 6-step feedback): Set the current loop proportional gain KIP based on the motor inductance to ensure loop stability.

The driver supports automatic motor configuration with SFD, loading default motor parameters to achieve robust performance. For advanced applications that require optimization, SelSFDParam can be manually adjusted to "Drive" through S200Tools to adjust motor parameters (KVP, KIP, DPOles, etc.), but caution must be taken to avoid damage.

Advanced configuration and functional block diagram

The S200 driver provides advanced control capabilities and can be deeply customized through the S200Tools software. The manual provides detailed control diagrams to help users understand signal flow:

Basic drive torque/speed control diagram: shows the complete path from command input (analog, PWM, variable), filtering and gain adjustment, to current loop, speed loop, and finally output to motor, including feedback and feedforward channels.

Basic driver position control diagram: A position ring has been added on the basis of the speed ring, supporting step/direction or A/B orthogonal command input, and scaling through gear ratio (GearIn/GearOut).

SynqNet Drive Torque/Speed Control Block Diagram: Highlighting the path of receiving commands and exchanging data through the SynqNet network, achieving synchronization and centralized control between multiple axes.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands