Kollmorgen SERVOSTAR-CD servo drive hardware installation and system configuration

Kollmorgen SERVOSTAR-CD servo drive hardware installation and system configuration

1. Product Overview and Safety Standards

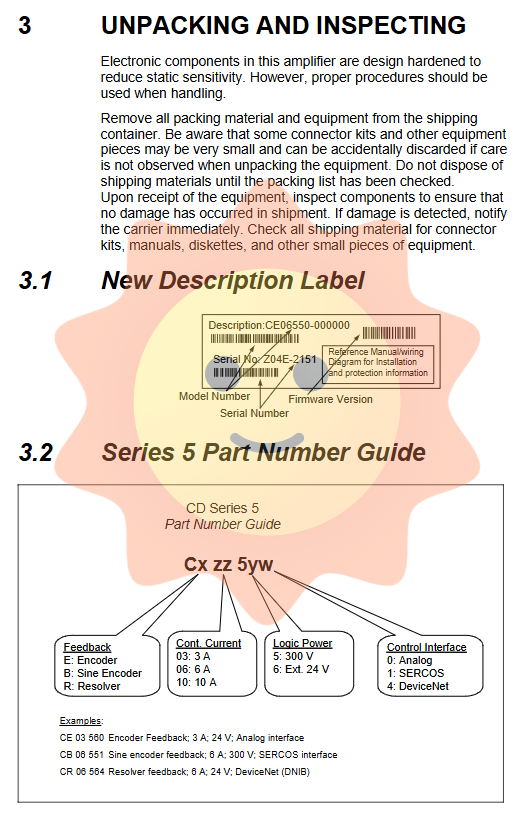

Danaher Motion's SERVOSTAR ® Since its launch in 1997, the CD series digital servo motor driver has become a mature solution in the field of industrial motion control. This series is divided into the early CD Series 2 (model number 5 is 2, such as CR06250) and the more powerful CD Series 5 (model number 5 is 5, such as CR06550). Series 5 is backward compatible with Series 2 in terms of hardware and functionality, and integrates more advanced digital signal processor (DSP) control technology, additional I/O, and a lower cost rotary transformer conversion solution, making it the preferred choice for new applications.

Safety is the primary prerequisite for installation and operation. This equipment is only allowed to be transported, assembled, debugged, and maintained by qualified personnel. Operators must be familiar with the installation and commissioning standards of motors and related equipment (such as IEC 364, DIN VDE 0100), and strictly comply with safety regulations. The equipment contains electrostatic sensitive components, which require electrostatic discharge before operation and avoid contact with high insulation materials. When powered on, do not plug or unplug the connector. After power off, wait for at least 10 minutes to ensure that the capacitor is fully discharged. If necessary, use an electric meter to measure and confirm.

The equipment has passed UL/cUL 508C certification (applicable to the US and Canadian markets) and meets the CE marking requirements of the European Union, including the Machinery Directive (89/392/EEC), Electromagnetic Compatibility Directive (89/336/EEC), and Low Voltage Directive (73/23/EEC). To ensure that the entire system complies with EMC standards, the machine manufacturer is responsible for the EMC compliance of the final system and strictly follows the installation recommendations in this document, especially the guidance on shielding, grounding, filter layout, and cable laying.

2. Hardware installation and environmental requirements

SERVOSTAR-CD drivers are designed for panel installation and should be placed in metal cabinets to ensure appropriate protection levels (such as IP30) and electromagnetic compatibility. Attention should be paid during installation:

Vertical installation for better heat dissipation.

Ensuring metal to metal contact between the driver's metal casing and backplate is crucial for controlling electrical noise, optimizing grounding, and EMC performance.

The installation backplate should be an unpainted metal surface to provide optimal electrical bonding and low impedance grounding path.

Adequate clearance distance should be maintained laterally and at the top/bottom (such as approximately 0.5 inches for lateral 16/14 AWG cables) to ensure heat dissipation and safety.

The hardware specifications vary depending on the model (Cx03, Cx06, Cx10), including weight, installation torque, connection screw specifications, and recommended wire diameters (such as 16 AWG/1.5 mm ² for control logic wires and 14 AWG/2.5 mm ² for motor power wires).

3. System wiring, grounding, and shielding technology

Proper wiring, grounding, and shielding are crucial for the long-term stable operation of the system and compliance with EMC standards.

3.1 General Wiring Principles

Separation of strong and weak electricity: Control and signal cables should be laid separately from power and motor cables, with a recommended minimum spacing of 20 centimeters. If crossing is necessary, it should be done at a 90 ° angle to minimize coupling interference.

Use shielded cables: All control and signal cables should be shielded to reduce radiated interference.

Cable laying: Power lines should be placed as close as possible to the backplane to allow for capacitive coupling of noise and current to the grounding plane. When the motor cable and feedback cable exit the cabinet, they should be separated as much as possible, ideally using separate metal tubes.

3.2 Grounding System

The system grounding needs to achieve two goals: safe grounding and high-frequency grounding.

Safe grounding: All system component frameworks must be connected to the ground through a star shaped grounding point.

High frequency grounding: provides an extremely low impedance grounding path for filters, drivers, and power supplies. Do not use ordinary wires as high-frequency grounding, as their inherent inductance will generate impedance at high frequencies. Flat braided tape or copper bars should be used and the length should be shortened as much as possible. The backplane needs to be connected to the cabinet frame and ground through a high-frequency grounding strip.

3.3 Shielded cable overlap

All shielding layers of shielded cables (motors, feedback cables) must be overlapped near the driver end to reduce the impedance between the shielding layer and the backplane, thereby suppressing noise emission and improving immunity.

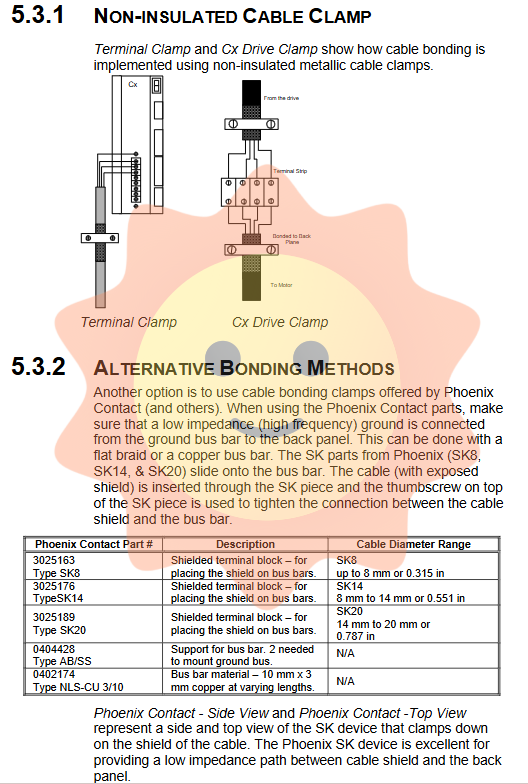

Method 1: Use non insulated metal cable clamps to directly clamp the exposed shielding layer onto the backplate.

Method 2: Use specialized connectors from Phoenix Contact and other brands (such as SK series) to connect the cable shielding layer to the grounding busbar.

If the power supply is introduced into the cabinet through a metal conduit, the power input line may not be shielded, but the metal conduit itself needs to be properly grounded. Otherwise, the power input line also needs to be shielded and properly overlapped.

4. EMC filtering technology

To meet the CE emission requirements in industrial environments, it is necessary to correctly apply input power filtering and add motor lines and I/O filtering as needed.

4.1 Input power filtering

Each driver (or a group of parallel drivers) needs to be equipped with an EMI line filter on the incoming power supply side. The filter should:

Install on the same backplane as the drive and as close as possible to the power inlet of the cabinet.

Install on unpainted metal surfaces to ensure good contact.

Reliable grounding (the internal capacitor of the filter may still have dangerous voltage after power failure).

Select the model with "line to line" and "line to ground" capacitors at the output end.

The document recommends Filter Concepts and Schaffner filter models for different driver models.

4.2 Motor line filtering

Although not necessarily necessary for CE compliance, motor line filtering can improve system reliability.

Differential mode noise: Long motor cables can exacerbate inter line capacitive coupling. A ferrite magnetic ring (such as Fair Rite P/N 2643665702) can be wound around each motor wire near the driver end for several turns to attenuate. Do not pass the ground wire through the magnetic ring.

Common mode noise: generated by PWM switching frequency. Common mode chokes (such as Schaffner RD series) can be used on motor lines to increase common mode impedance, protect encoders and I/O signals.

4.3 I/O filtering

Depending on the system environment, it may be necessary to use clamp type ferrite cores on the I/O lines to attenuate unwanted signals. For CD series drives, in order to meet CE requirements, a specific magnetic core (such as Fair Rite 2643167251) must be applied on the 24V input power line and remote enable line (C3 connector pins 7&8), and wound around the constraint for 3 turns.

4.4 Filtering and Overlapping System Diagram

The document provides a key schematic diagram of system wiring, filtering, and bonding, summarizing all best practices from power input, single point grounding, high-frequency grounding, filter grounding, motor/feedback cable bonding to strong and weak current separation wiring. It is the core reference for system integration.

5. Detailed explanation of connectors and wiring diagrams

SERVOSTAR-CD provides a wide range of connectors for power supply, motor, feedback, communication, and I/O.

5.1 Main connector functions

C1: RS-232/RS-485 communication port.

C2: Motor feedback connector (supporting rotary transformers, digital encoders, sine encoders).

C3: User I/O connector (analog input, remote enable, configurable input/output, fault relay, etc.).

C4: Encoder Equivalent Output (EEO) or SERCOS Interface (Fiber Port).

C8: Remote encoder input (for electronic gears or dual feedback).

C9 (Series 5 specific): Extended I/O interface.

Power terminals: main power input (L1, L2, L3), motor output (Ma, Mb, Mc), regenerative braking (B+, C -), logic power supply (24VDC), and ground (GND).

5.2 Wiring precautions

All AC power cords should use twisted pair cables.

It is best to connect the driver and motor grounding at a star shaped grounding point to minimize ground current and noise.

The cable shielding layer is only connected at one end (preferably the driver end), and if overlapping has been implemented, the end of the shielding layer does not need to be connected to the star point again.

Add a freewheeling diode to the inductive load output of O1 on C3.

Recommended wire specifications, terminal models, and torque values must be followed (such as power terminal screw torque typically being 20 lb in/2.26 N-m).

6. Feedback system configuration

The driver supports multiple feedback devices and needs to be configured according to the type.

6.1 Rotary Transformer

Requirement: Control transformer type, transformation ratio 0.47, excitation frequency 7-8 kHz.

Cable: It is recommended to use twisted pair shielding, with a length of up to 75 feet (22.9 meters). For longer distances, please consult the factory.

Resolution and accuracy: The system automatically configures the R/D converter resolution (up to 16 bits/65536 counts/rev) based on the speed limit (VLIM). The system accuracy is affected by factors such as R/D converter, mechanical, and installation errors, with a typical worst-case scenario of about 19 arcminutes.

6.2 Digital Incremental Encoder

Requirement: Differential A/B signal (with or without Index and Hall signals), 5VDC power supply, maximum input frequency of 3 MHz (before fourth harmonic).

Cable length: It is recommended not to exceed 50 feet (15 meters), as being too long can cause voltage drop. When traveling long distances, it may be considered to provide separate power supply for the encoder at the motor end.

Initialization: Depending on the encoder type (MENCTYPE 0-6), it may be necessary to perform a "wake-up swing" initialization process or use Hall signals to obtain rough positions during startup, and finally accurately locate through Index pulses (MENCOFF parameter).

6.3 Sine Encoder

Advantages: Output analog differential sine signals, and the driver can perform x256 interpolation internally, thereby obtaining extremely high resolution (line resolution x 256 x 4) at lower signal frequencies.

Type: Supports interfaces with Index, Hall, C/D signal (single speed rotary type), or Endat absolute type.

Calibration: After the first use or replacement of the motor/driver, it is necessary to run the Sine Zeroing (SINInitiat) process to compensate for the gain and offset of the sine/cosine signal and improve accuracy.

6.4 Encoder Equivalent Output (EEO)

The driver can provide orthogonal encoder signals corresponding to the motor position through the C4 connector, without the need for additional position sensors.

Rotary conversion system: generated by R/D circuit, with configurable resolution (ENCOUT), up to 16384 lines/rev (65536 quadruplex counting).

Encoder system: Directly outputs the actual encoder signal, which can be divided by multiples of 2 (ENCOUTO).

Sine encoder system: It is generated by dividing the interpolated signal by frequency (SININTOUT) and then encoding it.

Phase relationship: The rotation system is A leading B in a clockwise direction; The encoder/sine encoder system corresponds to the clockwise direction of A before B-ultrasound.

7. System communication and configuration software

7.1 Communication Method

Serial communication (C1): Supports RS-232 (point-to-point or multi-point daisy chain connected through C7) and RS-485 (only through C1 daisy chain). The baud rate is set through DIP switch 6 (9600/19200). Set the driver address (0-31) through DIP switches 1-5.

SERCOS interface (C4, dedicated model): high-speed digital communication through fiber optic ring network, supporting up to 31 axes. The address and non-zero power level need to be set through DIP switches.

7.2 MOTIONLINK Configuration Software

This is the main user configuration, debugging, and monitoring tool that runs on Windows systems.

Startup Wizard: Gradually guide the user to set the driver bus voltage, select/define the motor from the database, select the operating mode (OPMODE), and perform loop debugging.

Main interface: Provides comprehensive monitoring, variable editing, I/O configuration, tuning, data recording, and fault status viewing functions.

Terminal mode: allows experienced users to directly input variables and commands for configuration.

Parameter saving: Configuration parameters can be saved to the drive EEPROM or exported as SSV files are used for backing up or cloning to other drives.

7.3 System enablement and status display

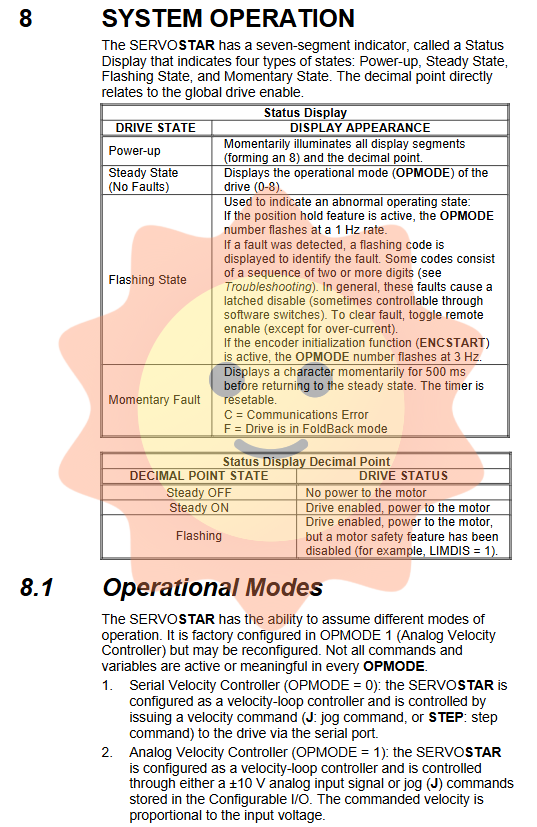

The status display on the front panel of the drive indicates the system status:

Number: Display the current operating mode (OPMODE).

The decimal point is constantly on: the driver is enabled and the motor is powered on.

Flashing: may indicate position retention activation, malfunction (displaying fault codes), or encoder initialization in progress.

Active is the result of the combined action of software enable (SWEN), fault free (DRIVE OK), hardware remote enable (REMOTE), and DIP enable switch (DIPEN).

8. Control loop and operating mode

SERVOSTAR adopts fully digital control, with a core of 40MHz embedded controller and DSP.

8.1 Control Loop

Current loop (torque loop): update rate of 16 kHz (62.5 μ s), bandwidth<2400 Hz, using pole placement digital algorithm.

Reversing loop: update rate of 16 kHz, converts single-phase current commands into three-phase sine waves, and optimizes motor performance using torque angle lead technology.

Speed loop: update rate of 4 kHz (250 μ s), bandwidth<400 Hz. Provides various compensators (COMPMODE) such as PI, PDFF, standard pole configuration, etc.

Position loop: update rate of 2 kHz (500 μ s). Supports multiple modes such as electronic gear (OPMODE 4) and positioning control (OPMODE 8).

8.2 Main Operating Mode (OPMODE)

0- Serial speed control

1- Simulated speed control (± 10V)

2- Serial torque control

3- Simulated torque control (± 10V)

4- Electronic gear position control (pulse following)

5- SERCOS interface control

8- Position control (supports serial/analog commands)

9. Protection function and troubleshooting

9.1 Protection Function

Turnback protection:

Driver turn back: protects the electronic components of the driver and prevents continuous overcurrent.

Motor turn back: protects the motor from continuous overcurrent causing overheating. Users can fully configure it.

Hardware limit: Implemented through configurable inputs (IN1-IN3), it prohibits movement in the corresponding direction when triggered.

Software limit: Set the position soft limit through variables.

Thermal protection: Monitor the temperature of the motor thermistor and driver heat sink.

Fault relay: can be configured to indicate "driver ready" or "driver running".

9.2 Troubleshooting Tools

Status display: indicates faults through flashing codes (such as "P" for power level faults and "o" for overvoltage).

MOTIONLINK status screen: Detailed display of enable status, fault history, and various protection settings.

Error codes: Divided into fatal faults (stopping almost all functions), non fatal faults (disabling drivers), and warnings. Error messages (ERR) and history records (FLTHIST) can be viewed through the serial port.

Common faults include overheating, overvoltage/undervoltage, overcurrent, feedback loss, overspeed, power failure, EEPROM error, etc. Most faults can be reset by switching to Remote Enable, but severe faults such as power level overcurrent require power cycling.

9.3 Firmware Upgrade

The firmware of the drive can be upgraded on-site using the Ignite. exe tool via serial port. Before upgrading, the driver needs to be disabled. After upgrading, the power supply needs to be cycled and the motor compensation file or user configuration file needs to be reloaded.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands