MKS 979B Atmosphere to Vacuum Transducer

MKS 979B Atmosphere to Vacuum Transducer

Product basic information

The 979B Transducer is designed to measure vacuum chamber pressures as part of a user’s designed system processes. It combines a Hot Cathode sensor to measure pressures from 5x10 (5 ×10^{-10}) to (3 ×10^{-3}) Torr and a MicroPirani sensor to measure pressures from 1x10 (1 ×10^{-3}) to ATM. PR3 the combined absulute digital pressure output and the analog output provides a single combined reading from 5x10 (5 ×10^{-10}) Torr to ATM. In addition the two sensors can be read independently. Along with an analog output external controls are available for filament select degas so the transducer (often set point values, calibration values ect. have been entered) can operate independently.

Safety and General Specifications

1. Safety warnings and preventive measures

Electrical safety: When replacing sensors or baking, the power supply must be disconnected first (there may be fatal voltage/current), and only qualified technicians can operate electronic components; Use+24 VDC@0.75 Amps power supply, ensure that the sensor is grounded through the vacuum flange and electrical connector rear housing.

Operation restriction: Do not turn on the filament power supply when the system pressure is higher than 5 × 10 ⁻ Torr (which may damage the hot cathode sensor); Prohibited from use in explosive/flammable gas environments (hot cathode heating elements, MicroPirani's nickel film elements may ignite gases); Do not replace parts or modify equipment. Repairs must be sent to the MKS calibration service center.

Pollution protection: prevent dust, metal shavings and other pollutants from entering the equipment; During installation, stay away from electronic/ion sources and strong magnetic fields. If necessary, use a particulate filter (see "Accessories" section for details).

2. General technical specifications

Specific project parameters

Measurement range 5 × 10 ⁻¹⁰ Torr to atmospheric pressure (ATM)

Set point range 5 × 10 ⁻¹⁰ Torr to 100 Torr

Analog output DAC1: 0.5-6.95 VDC (0.5 V/order of magnitude); DAC2: 0.75-10.02 VDC (0.75 V/order of magnitude)

Overvoltage limit of 1500 Torr

Repeatability (typical value) 1 × 10 ⁻⁹ -10 ⁻³ Torr: ± 5% reading; 10 ⁻ -100 Torr: ± 2% reading

Accuracy (typical value) 10 ⁻⁹ -10 ⁻³ Torr: ± 20% reading; 10 ⁻ -100 Torr: ± 5% reading

Supply voltage 24 VDC ± 10%

Power consumption 15 Watts

Rated value of relay contacts 1A@30 VAC/VDC (resistive load), compliant with Semi 52/UL991 safety standards

Vacuum contact material 304 stainless steel, silicon, SiO ₂, SiN ₄, gold, fluororubber (Viton) ®)、 Glass, tungsten, platinum molybdenum plating, yttrium oxide coated iridium, epoxy resin, Kovar alloy

Shell material aluminum/304 stainless steel

Internal volume 23 cm ³

Working temperature 0-40 ℃

Baking temperature (non working state) 85 ℃

Installation direction in any direction

EU certification complies with EMC Directive 89/336/EEC (EN-61326-1) and Low Voltage Directive 73/23/EEC (EN-61010-1)

Vacuum connection methods Mini CF, 2.75 "CF, NW16 KF, NW25 KF, NW40 KF

Size (with KF25) 74 × 79.6 × 100 mm (2.9 "× 3.1" × 3.9 ")

Weight (with KF25) 422 g (0.93 lbs.)

Installation Guide

1. Installation position and direction

Location selection: It is necessary to be able to accurately measure the pressure in the vacuum chamber, away from the pump and gas source to ensure representative readings; Avoid installing directly above the evaporation source (steam may contaminate the sensor), and shield and stay away from strong magnetic fields when approaching electronic/ion sources.

Installation direction: Supports installation in any direction, it is recommended that the vacuum port face downwards (to prevent particles/liquids from entering), which does not affect measurement accuracy.

2. Vacuum connection

The sensor offers multiple flange types: 2.75 "CF (rotatable), 1.33" CF (rotatable) KF16、KF25、KF40, Corresponding flanges need to be matched according to the system, and the manual provides dimension drawings of each flange for reference.

3. Electrical connection

Cable requirements: Use a 15 pin high-density D-sub female cable with strain relief; To meet the anti-interference requirements of EN61326-1, braided shielded cables are required, with metal hooks connected at both ends of the shielding layer and the power supply grounded.

Pin function: The 15 pin D-sub connector has clear pin division, and the core pins include: 1 pin (RS485-/RS232 TXD), 2 pins (RS485+/RS232 RXD), 3 pins (power+24V), 4 pins (power -), 5 pins (analog output+), 6 pins (analog output -), 9 pins (degassing state), 10 pins (filament selection), 13 pins (degassing on), as well as the common terminals (7, 11, 14 pins) and normal terminals (8, 12, 15 pins) of 3 relays. For details, please refer to the "979B Sensor Electrical Connection Table".

Attention: The negative terminal (6-pin) of the analog output should not be connected to the negative terminal (4-pin) of the power supply or other grounding points (which may cause current diversion and measurement errors, and the longer the cable, the greater the error); When connecting inductive loads (such as solenoids and transformers), an arc extinguishing network (resistor R and capacitor C) needs to be installed. The calculation formula is

C=I 2/(1 × 10 7) (Farads), R=E/I a (ohms, where a=1+(50/E)), and R is at least 0.5 Ω and C is at least 1.0 × 10 ⁻⁹ F.

Operation control

1. Control and status pin operation

Degassing on (Pin13): Enable degassing when grounded, with priority higher than DG command or degassing button; After 30 minutes of degassing, it is necessary to disconnect and reconnect to restart degassing, and degassing should not exceed 30 minutes every 4 hours.

Degassing state (Pin9): When degassing is closed, it is open circuit/suspended, and when it is open, it is grounded; An external pull-up resistor with ≤ 24 VDC can be connected, and the current should be less than 15mA.

Filament selection (Pin10): By switching the active filament on/off the power supply, the state can be switched instead of selecting a fixed filament.

2. Factory default settings

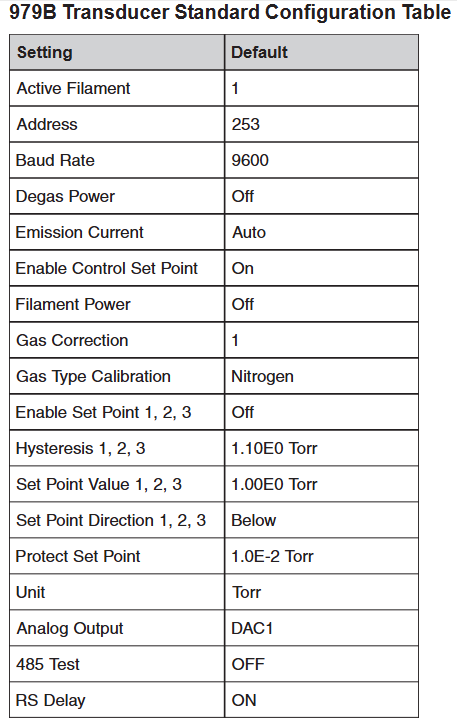

The sensor parameters are preset to default values, including: active filament 1, address 253, baud rate 9600, degassing power off, automatic emission current (20 μ A>1 × 10 ⁻⁴ Torr, 1mA<1 × 10 ⁻⁴ Torr), control set point enabled, filament power off, gas correction 1, gas calibration type nitrogen, 3 set points disabled, hysteresis value 1.10E0 Torr, set point value 1.00E0 Torr, set point direction "below (BELOW)", protection set point 1.0E-2 Torr, unit Torr, analog output DAC1, RS485 test off, RS delay on.

3. RS-485/RS-232 communication protocol

Basic parameters: Supports baud rates of 4800-112200 (default 9600), data format of 8-bit data bits, no checksum, and 1-bit stop bit; RS-485 is a half duplex two-wire system, which is the same protocol as RS-232.

Address rule: Standard address 001-253 (default 253); Universal address 254 (used for communication with unknown address devices, will respond), 255 (broadcast address, executes commands but does not respond, such as batch modification of baud rate).

Command syntax: The query format is @<device address><query command>?; FF (such as querying baud rate: @ 253BR?)?; FF), The command format is @<device address><command instruction>! <Parameters>; FF (such as changing the baud rate to 19200: @ 253BR! 19200; FF); The response starts with ACK (success) or NAK (failure), and the NAK code corresponds to different errors (such as 160=unrecognized message, 169=invalid parameter, 172=value out of range, etc.).

4. Core Command Set

The commands are divided into five categories: setting, status, pressure measurement and degassing, set point, and calibration. The core commands are as follows:

Command Type Command Identification Function Description Example

Set command AF (active filament) to query/select 2 filaments (value 1/2) of the hot cathode sensor. Query: @ 001AF?; FF; Setting: @ 001AF! 2; FF

AD (Address) Query/Set Device Address (001-253) Query: @ 254AD?; FF; Setting: @ 001AD! 002; FF

BR (baud rate) query/set baud rate (4800/9600, etc.) query: @ 001BR?; FF; Setting: @ 001BR! 19200; FF

DAC (Analog Output) Query/Set Analog Output Type (1=DAC1, 2=DAC2) Query: @ 001DAC?; FF; Setting: @ 001DAC! 2;FF

FD (factory default) restores all user calibration values to factory default command: @ 001FD!; FF

Status command DT (device type) query device type response: @ 001ACKMP-HC 979B; FF

FS (filament status) query for the on/off status of the active filament: @ 001FS?; FF

FV (firmware version) query firmware version response: @ 001ACK1.00; FF

SN (serial number) query device serial number response: @ 001ACK0000012345; FF

T (sensor status) query hot cathode status (F=filament fault, G=hot cathode on, etc.) Response: @ 001ACKO; FF (O=normal)

Pressure measurement and degassing FP (filament power supply) switch filament power supply (only effective when the control setpoint is disabled, disabled when the pressure is greater than 5 × 10 ⁻ Torr) command: @ 001FP! ON; FF

DG (degassing power supply) switch degassing (pressure must be<1 × 10 ⁻⁵ Torr, automatically shuts off after 30 minutes) query: @ 001DG?; FF; Setting: @ 001DG! ON; FF

PR1/PR2/PR3 (pressure readings) respectively read MicroPirani (PR1, above 1 × 10 ⁻³ Torr), hot cathode (PR2, below 1 × 10 ⁻⁴ Torr), and combined reading (PR3, full range). Query: @ 001PR1?; FF; Response: @ 001ACK1.23E-2; FF

The set point command SPx (set point value) queries/sets the pressure values (Scientific notation) of the three set points: @ 001SP1! 1.00E-3; FF

SDx (Setpoint Direction) Query/Set Setpoint Direction (BELOW/ABOVE) Setting: @ 001SD1! ABOVE; FF

SHx (hysteresis value) query/set the set point hysteresis value (to avoid relay jitter and match direction) setting: @ 001SH1! 1.10E-3; FF

ENx (Enable Setpoint) Enable/Disable 3 Setpoint Commands: @ 001EN1! ON;FF

Calibration command ATM (atmospheric pressure calibration) to calibrate MicroPirani to full range (requires ventilation to atmospheric pressure, stable for 20 minutes) Command: @ 001ATM! 7.60E+2; FF

VAC (vacuum calibration) calibration MicroPirani zero point (needs to be drawn to<1 × 10 ⁻⁴ Torr, stabilized for 20 minutes, automatically calibrated when hot cathode pressure<1 × 10 ⁻⁴ Torr) command: @ 001VAC!; FF

GT (gas type) query/setting MicroPirani's measurement gas (nitrogen/air/argon, default nitrogen) setting: @ 001GT! ZEROGEN; FF

GC (gas correction) query/set gas correction coefficient for hot cathode (0.10-50.1, default 1, such as argon 1.29) setting: @ 001GC! 1.29; FF

Analog output and gas correction

1. Simulation output calculation and table

DAC1: Pressure calculation formula P=10 (2V − 11) (Torr), the manual provides a detailed voltage correspondence table for 1.0E-10 Torr (0.50V) to 1.0E+03 Torr (7.00V).

DAC2: Pressure calculation formula P=10 0.75 V − 7.75 (Torr), also provide a complete pressure voltage correspondence table.

2. Gas correction factor

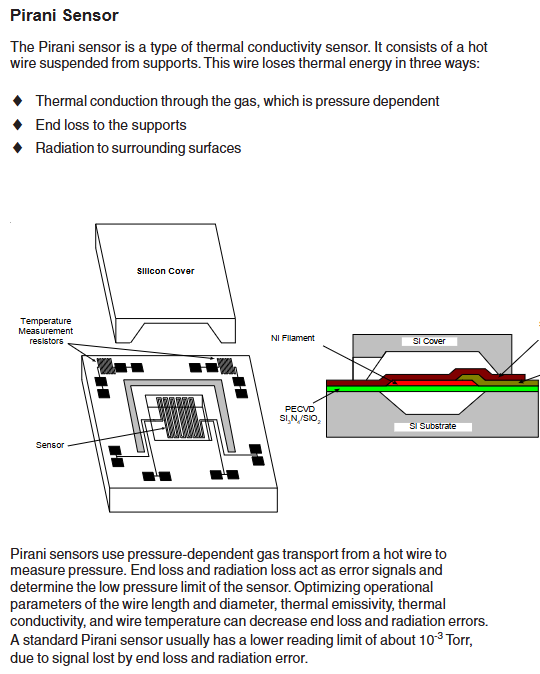

MicroPirani is based on gas thermal conductivity measurement, and the hot cathode is based on gas ionization measurement, both of which need to be corrected according to the gas type:

Gas chemical formula gas correction factor (GC)

Air -1.00

Argon gas Ar 1.29

Carbon dioxide CO ₂ 1.24

Deuterium gas D ₂ 0.35

Helium He 0.18

Hydrogen H ₂ 0.46

Krypton gas Kr 1.94

Neon gas Ne 0.30

Nitrogen N ₂ 1.00

Nitric oxide NO 1.16

Oxygen O ₂ 1.01

Sulfur hexafluoride SF ₆ 2.50

Water H ₂ O 1.12

Xenon Xe 2.87

Maintenance and troubleshooting

1. Daily maintenance

Cleaning: The casing can be cleaned with water or alcohol to prevent liquids from entering the electronic casing; The sensor tube must not be cleaned (as it may damage the components), and the sensor needs to be replaced in case of severe contamination.

Degassing operation: When the hot cathode sensor is contaminated by process gas (especially when the sensitivity drifts when the pressure is ≤ 10 ⁻⁸ Torr), regular degassing is required; When degassing, the pressure should be less than 1 × 10 ⁻⁵ Torr. During this period, the pressure can be measured but the reading may be higher than the system pressure. When the pressure is greater than 1 × 10 ⁻⁴ Torr, degassing is paused and restarted after reaching the threshold. It will automatically terminate after 30 minutes, and degassing should not exceed 30 minutes every 4 hours.

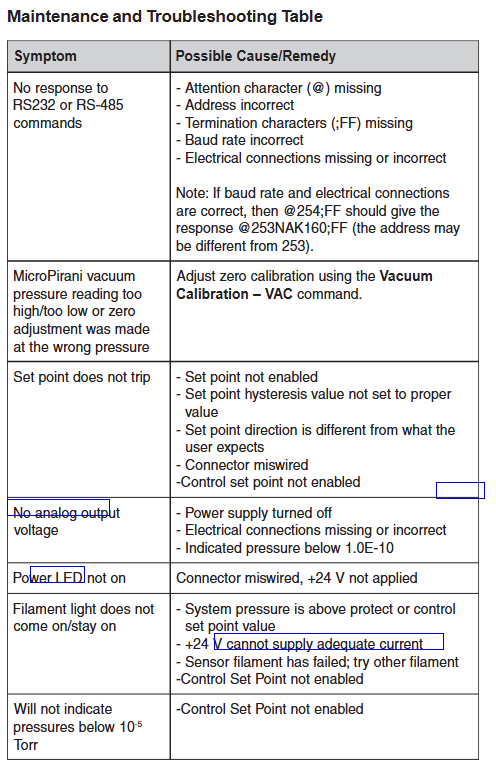

2. Common faults and solutions

Possible causes/solutions for the fault phenomenon

RS-485/RS-232 no response 1. Missing starting character @; 2. Address error (you can try @ 254; FF query); 3. Missing termination character; FF; 4. Baud rate mismatch; 5. Missing/incorrect electrical connections

MicroPirani reading too high/too low/

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands