ABB REF601 digital feeder protection device

ABB REF601 digital feeder protection device

Core functions of the device

Protection function

Overcurrent protection:

Three stage overcurrent protection (I>, I>>, I>>>), supporting timed and inverse time characteristics (compliant with CEI 60255 standard), covering short-circuit faults.

The inverse time limit feature can be selected as "normal inverse time limit" or "extreme inverse time limit", adapting to the action logic under different fault current levels.

Ground fault protection:

Two stage non directional grounding fault protection (I ₀>, I ₀>>), detects grounding faults through zero sequence current, and the action value can be set to 1% -800% of the rated current, supporting timed delay (0.02-60s).

Cable thermal overload protection:

Based on the current based thermal accumulation model, the cable temperature (θ>) is monitored to prevent insulation aging caused by long-term overload. The alarm/trip threshold can be set to 50% -100% of the rated temperature, with a time constant of 1-200 minutes.

Other auxiliary protections:

Phase sequence interruption protection (Δ I>): detects three-phase current imbalance, with an action value of 10% -100% (based on maximum/minimum phase current difference), and a delay of 1-300s.

Circuit Breaker Failure Protection (CBFP): Monitor circuit breaker faults, with an action time of 0.1-60 seconds, in conjunction with external fault detection logic.

Measurement and monitoring functions

Measurement quantity: Real time monitoring of three-phase current, residual current, phase imbalance, thermal overload level, 1-minute current demand and maximum value, with accuracy in accordance with IEC 61557-12 standard.

Event record: Store 100 events with time stamps (protection start, trip, self-test fault, etc.), without loss during power outage, and support reading through local interface.

Fault waveform recording: Record 4 analog signals (current waveform) and 8 digital signals (protection signal, circuit breaker status), non-volatile storage for easy analysis after faults.

Self monitoring function: Real time monitoring of power supply, hardware modules, and communication status, triggering alarms in case of faults to ensure device reliability.

Control and Communication

Control function: Supports local/remote opening and closing control of circuit breakers, adopts a "select execute" mechanism to prevent misoperation, and has built-in trip circuit monitoring (TCS) to monitor the integrity of the control circuit.

Communication interface: Standard RS485 interface, supports Modbus RTU protocol, can be connected to power distribution automation system (SCADA), realize remote parameter tuning, data uploading and status monitoring.

Hardware and Technical Parameters

Hardware structure

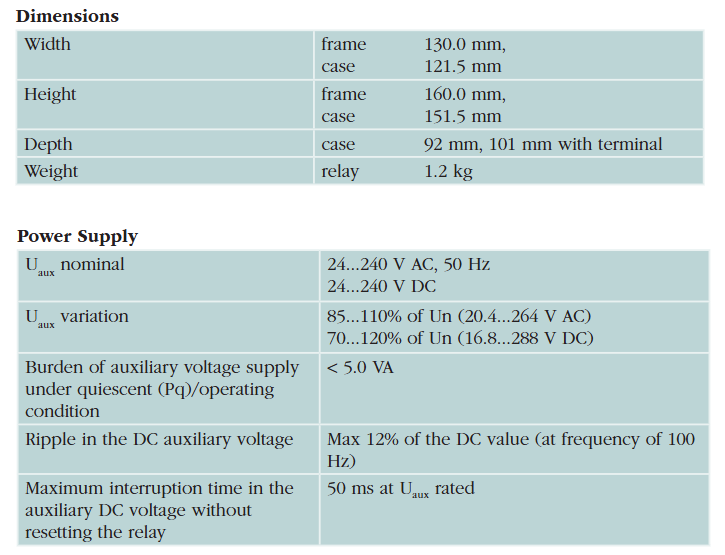

Compact design: Small in size (approximately 100mm x 160mm x 120mm in width x height x depth), suitable for embedded installation in small switchgear (such as ABB UniGear series).

Input/output:

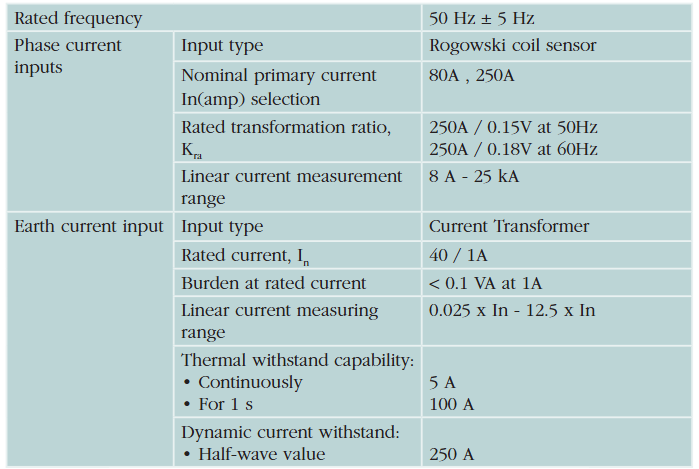

Current input: Supports 1A or 5A rated CT, 3 phase currents+1 zero sequence current, low input impedance (<20m Ω at 5A).

Digital input: 2 main inputs (supporting 24-250V DC), expandable to 5 channels, response time<3ms.

Relay output: 2 trip outputs (SO1, SO2), 1 alarm output (SO3), rated current 5A (continuous), 30A (short-term 0.5s).

Key technical parameters

Power supply: Supports 24/48/110/220V DC or 110/230V AC, power consumption<8W (static),<12W (running), voltage fluctuation range ± 20%.

Environmental adaptability: working temperature -25 ℃~+55 ℃, storage temperature -40 ℃~+85 ℃, anti vibration (10-150Hz), anti electromagnetic interference (in accordance with IEC 61000-4 series standards).

Accuracy level: Current measurement level 0.5, protection setting error<± 5%, time error<± 5% or ± 50ms (whichever is greater).

Application scenarios

Typical applications: feeder protection for medium and low voltage distribution networks (cables/overhead lines), backup protection for small transformers, and protection for industrial distribution circuits.

Adaptation system: Italian local distribution system that meets CEI standards, especially suitable for small switchgear with strict space requirements, can replace traditional electromagnetic relays, improve protection accuracy and automation level.

Operation and maintenance

Local operation: Basic operations are achieved through panel buttons and LED indicator lights (run, alarm, trip), supporting local parameter tuning (password permission required).

Debugging tool: It is necessary to connect the device through specialized software (such as ABB PCM600 simplified version) for parameter configuration, fault record reading, and firmware upgrade.

Installation requirements: Reliable grounding (grounding resistance<10 Ω) is required to avoid close installation with strong interference sources (such as contactors and frequency converters), ensuring measurement accuracy and anti-interference ability.

Summarize

REF601 focuses on the basic protection needs of medium and low voltage distribution systems with "compact, reliable, and practical" as its core. By integrating protection, measurement, and communication functions, it simplifies switchgear design and adapts to the CEI standards of the Italian market. It is an economical choice for small distribution circuit automation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands