RELIANCE ELECTRIC INVERTRON DBU Dynamic Braking Unit

Safety Compliance and CE Installation Guidelines

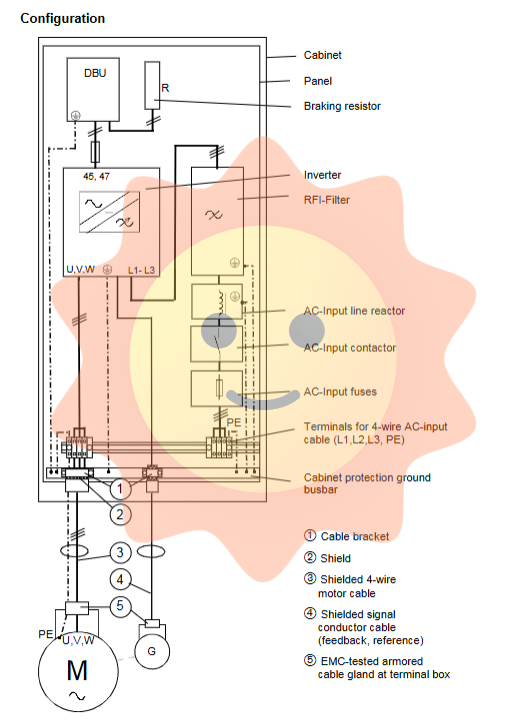

As a component covered by the Mechanical Directive and EMC Directive, the integration of DBU must comply with specifications.

Safety first: Only qualified electrical personnel familiar with this type of equipment are allowed to install and operate it. Before operation, it is necessary to understand the manual and disconnect the module only after power is turned off.

The key to meeting CE/EMC requirements is:

Complete Faraday cage: All drive components (frequency converter, filter, DBU, braking resistor) should be installed in a common metal control cabinet or individually placed in a metal casing. The cabinet or shell should ensure good electrical continuity.

Grounding is the soul: all component protective grounds (PE) must be connected to the power supply incoming PE point without interruption through yellow and green wires. A common grounding copper bar should be installed inside the cabinet.

Shielding and wiring:

All external power cables (such as DBU to resistors) must use shielded cables or separate metal tubes.

Signal and control cables must use shielded cables, with both ends of the shielding layer grounded.

The motor cable should be a four core shielded cable with a three-phase grounding wire.

Use cable connectors that have undergone EMC testing to ensure that the shielding layer has a 360 ° large-area contact.

Installation details: Components should be installed on unpainted conductive mounting plates to maximize contact area. It is recommended that the diameter of the ventilation hole should not exceed 6mm. The distance between the braking resistor and the housing should be at least 100mm.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands