REXROTH 4WRPEH series Directional control valves

2. IO Link Integration and Security Shutdown

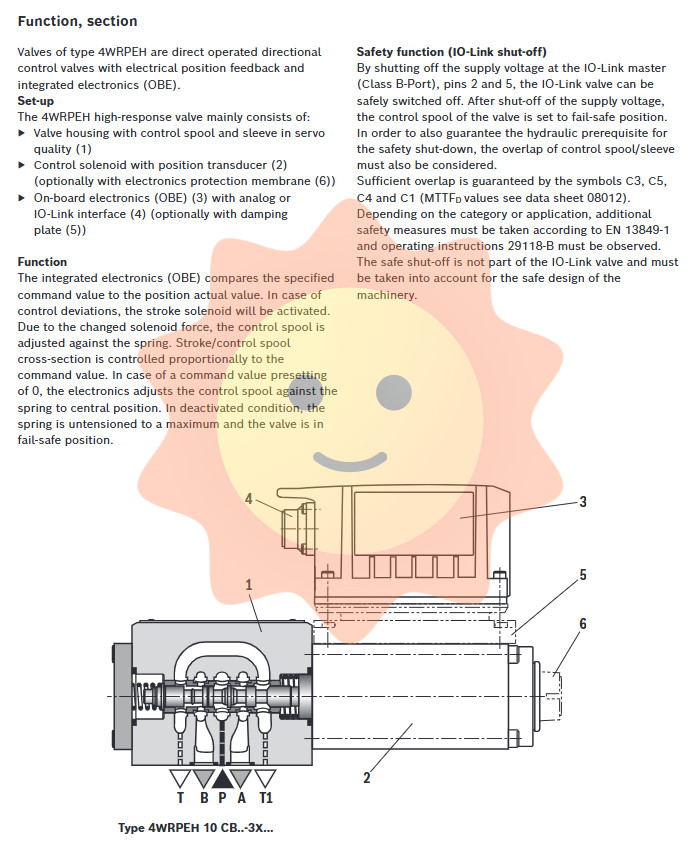

The IO Link interface (L1 type) is not only a digital communication channel that replaces analog signals, but also brings revolutionary features:

Parameterization and diagnosis: All valve parameters, such as gain and ramp time, can be easily set and saved through software. Can read detailed diagnostic data, such as temperature, current, fault codes, etc.

Safe shutdown: By cutting off the power supply to pins 2 and 5 of the IO Link master station (Class B port), the valve can be safely closed and placed in a fail safe position. Combined with valve cores with sufficient coverage (such as C3, C5, C4, C1 types), this function can be used to construct safety related control circuits that comply with EN 13849-1 standards, up to Category 3, PL d. Machine manufacturers need to implement additional safety measures and periodic diagnostics according to standards.

Internal fault monitoring: OBE continuously monitors its own status. When low power supply voltage, IO Link communication interruption, watchdog timeout, or internal error is detected, the electromagnetic power supply will be automatically cut off, allowing the valve to enter the fault safe position.

3. Damping plate and protection

Damping plate "D": an optional accessory used to suppress high-frequency vibrations (>300 Hz) transmitted externally to the valve and protect internal precision electronic components. However, it is not recommended to use it for applications primarily subjected to low-frequency excitation (<300 Hz).

Electronic protective film "967": As mentioned earlier, it is used in harsh environments to prevent condensation.

Detailed technical data and performance boundaries

1. Hydraulic and medium conditions

Maximum working pressure: A, B, P ports: 350 bar; T port: 250 bar.

Hydraulic oil: compatible with mineral oil (HL, HLP), biodegradable oil (HETG, HEES, HEPG), and flame retardant hydraulic fluid (HFC, HFDU). The selection of oil directly affects the sealing compatibility, temperature range, and component life, and strict reference to the compatibility table is required.

Oil cleanliness: extremely high requirements, must meet ISO 4406 18/16/13 level. This is the key to ensuring long lifespan and reliability.

Usage restrictions: To ensure reliable fault safety functions, different valve core functions have limitations on the working pressure difference (350 bar for C3 and C5 models; C1 and C4 models are 250 bar).

2. Electrical characteristics

Power supply: All electronic interfaces require a 24 VDC power supply, with slightly different allowable ranges (e.g. A1/F1/C6 type: 19-36 VDC; L1 type valve amplifier: 18-30 VDC.

Protection level: When using a suitable and correctly installed docking plug, it can reach IP65.

EMC installation: To achieve electromagnetic compatibility, metal docking plugs must be used and the cable shielding layer must be grounded at both ends. If only grounded at one end, a plastic plug can be used, but the cable length is allowed to be shortened.

3. Dynamic performance and characteristic curve

The document provides detailed characteristic curves of HLP46 hydraulic oil at 40 ° C, including:

Flow signal characteristic curve: visually displays the relationship between the command signal and the flow rate between each oil port under L-shaped and P-type flow characteristics.

Step response curve: displays the response time of the valve to different amplitude command steps, reflecting its high dynamic performance.

Frequency response curve: describes the amplitude and phase response of the valve under different frequency sine signal excitations, and is the key to evaluating the dynamic stability of the system.

Leakage volume at the fault safe position: lists the internal leakage volume between each oil port in the power-off (fault safe) state, which is crucial for system pressure maintenance design.

Installation, wiring, and accessories

1. Mechanical installation

Adopting the bottom plate installation method of ISO 4401-05-04-05 standard.

Installation must be carried out using specified hexagon socket head screws (such as ISO 4762-M6x40) and specified tightening torque (such as 12.5 Nm ± 10%) to ensure sealing and pressure bearing capacity.

The installation surface must meet the specified surface processing quality.

2. Electrical connection

Analog interfaces (A1, F1, C6): Use 6-pin+PE circular connectors. The pin definition is clear, and attention should be paid to the polarity of the instruction value: positive signals cause P → A/B → T to flow; Negative signal causes P → B/A → T flow.

IO Link interface (L1): using M12-5 pin, A-code connector. Among them, Pin2 (P24) and Pin5 (N24) are the valve electronic devices and power stage power supplies; Pin1 (L+) and Pin3 (L -) provide power to the IO Link communication interface; Pin4 (C/Q) is the data cable. Pin3 and Pin5 are already connected inside the valve, and L - and N24 must also be connected together on the power supply side.

3. Recommended attachments

Docking plugs and cables: Bosch Rexroth offers a variety of prefabricated shielded cable components ranging in length from 1.5 meters to 20 meters, strongly recommended for use to ensure EMC performance.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA