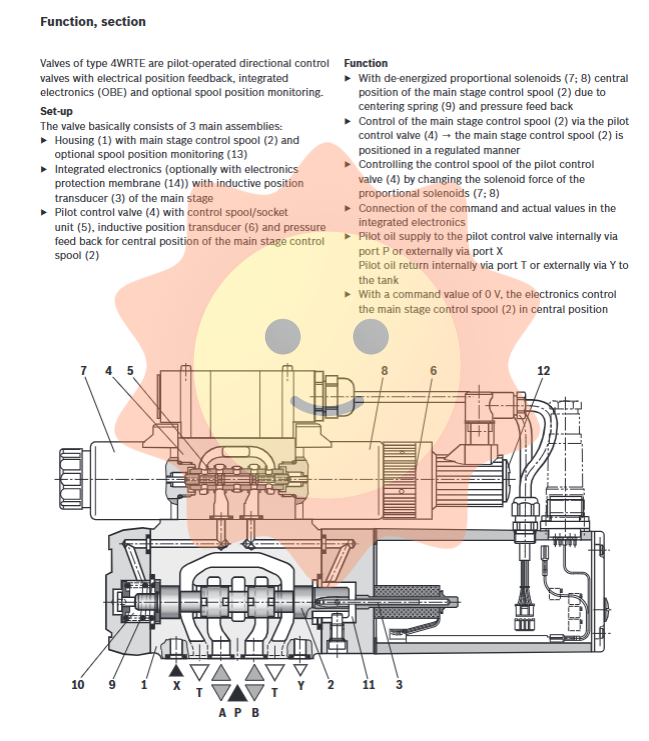

REXROTH 4WRTE type electro-hydraulic proportional directional valve

Key Technical Parameters and Selection Guidelines

1. Hydraulic performance parameters

Working pressure: The maximum pressure for main oil ports P, A, and B is 315 bar; Return port T can reach a maximum of 350/370 bar (depending on specifications); The maximum pressure for the external pilot return port Y is 250/315 bar.

Rated flow rate: defined at a valve port pressure difference Δ p=5 bar, carefully selected based on the model size and valve core symbol (such as E, V, W, etc.). For example, NG10 has options of 25, 50, and 100 l/min; NG35 can reach up to 1000 l/min.

Flow characteristics: Linear (L) or linear (P) with fine tuning zone can be selected, the latter providing finer control resolution at small aperture.

Hydraulic oil and cleanliness: Supports mineral oil (HL, HLP, etc.), biodegradable oil (HETG, HEES), and flame retardant hydraulic fluid (HFD, HFC). The system cleanliness requirements are strict and must meet ISO 4406 18/16/13 levels, otherwise it will affect performance and lifespan. When using water-based flame retardant liquid (HFC), there are additional pressure, temperature, and lifespan limitations.

2. Electrical and electronic characteristics

Power supply: 24 VDC (allowable range 18-35 V), maximum ripple of 2.5 Vpp. The maximum current consumption is 1.6 A, the peak current is 2.7 A, and a 4A delay type external fuse is required.

control interface

A1: Differential input, ± 10 V command/actual value.

F1:4... 20 mA command/actual value input.

A5: ± 10 V command/actual value, with enable signal pin (high level 11... UB V effective). Special reminder: When upgrading from the 3X series to the 4X series, the electronic interface must be defined as A5.

Protection level: After the connector is plugged in and locked, the electronic part reaches IP65 protection level.

Coil temperature: up to 150 ° C, attention should be paid to thermal management and operational safety of the installation space.

3. Pilot oil supply options (key selection points)

This is an important part of the ordering code that determines the source and return method of the pilot oil:

No code: External pilot oil supply (X port), external pilot return oil (Y port).

Code "E": Internal pilot oil supply (taking oil from port P), external pilot return oil (port Y). The X port needs to be blocked on the bottom plate.

Code "ET": Internal pilot supply oil, internal pilot return oil (to T port). The X and Y ports need to be blocked on the bottom plate.

Code "T": External pilot supply oil (X port), internal pilot return oil (to T port). The Y port needs to be blocked on the bottom plate.

Suggestion: For applications where the system pressure is above 210 bar or water-based flame retardant fluid is used, it is recommended to use external pilot oil supply to ensure pilot control stability and valve life.

Key points for installation, debugging, and maintenance

1. Size and installation

The valve provides a bottom plate connection surface that complies with ISO 4401 standard. Each specification (NG10 to NG35) has detailed installation dimension drawings, and attention should be paid to leaving sufficient space for connecting cables and plugging connectors. During installation, it is necessary to use high-strength hexagonal socket head screws (strength grade 10.9) of the specified specifications and tighten them with the precise torque specified in the document (such as 13.5 Nm ± 10% for M6 screws of NG10). This torque value is crucial for setting the maximum working pressure.

2. Electrical connection

The main electronic device is wired through a 6-pole+PE circular connector. It is recommended to use shielded cables (such as LiYCY type) and connect the shielding layer only to the PE on the power supply side.

The valve core position monitoring sensor is independently wired through a 4-pole M12x1 connector, powered by 20-32 VDC, and provides two maximum 400 mA PNP switch outputs.

Important warning: The signals provided by valve electronic devices (such as actual value feedback) must not be used for the shutdown of safety related machine functions. Safe shutdown must be achieved by safely disconnecting the power supply to the valve.

3. Debugging and zero calibration

The valve has completed zero calibration (accuracy ≤ 1%) at the factory. Users are strictly prohibited from attempting to mechanically adjust the PG plug on the valve body (which has an adjusting nut inside), otherwise it may damage the valve.

If the pilot valve or electronic equipment is replaced, it must be recalibrated by trained professionals, otherwise it may cause system damage.

The zero temperature drift is extremely small (<0.3%/10 ° C), ensuring long-term stability during operation.

Typical Applications and Selection Summary

The 4WRTE series valves are highly suitable for application in:

Speed and pressure control of high-precision injection molding machines and presses

Load simulation and position servo control of test bench

Intelligent hydraulic control system for large construction machinery such as shield tunneling machines and cranes

Any industrial hydraulic power shaft control that requires high reliability, high repeatability, and may involve safety monitoring

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA