REXROTH IndraDyn S MSK series synchronous servo motor

REXROTH IndraDyn S Series MSK Synchronous Servo Motor Application Guide

Introduction

In the field of modern industrial automation, high-precision, high dynamic response, and high reliability servo drive systems are the embodiment of core competitiveness. The IndraDyn S series MSK synchronous servo motor under Bosch Rexroth has established a benchmark position in key industries such as machine tools, printing, packaging, and robotics with its wide power spectrum, fine machine base number grading, and maximum torque of up to 631 Nm. This guide aims to provide a comprehensive technical review and application analysis of this series of motors based on the official project planning manual, offering a one-stop professional reference for design, selection, installation, and maintenance personnel.

Product Overview and Design Concept

The MSK series motor is a permanent magnet synchronous servo motor, whose core design concept is to achieve extremely high torque density and compact structure. The motor has a standard protection level of IP65 and integrates a temperature sensor to ensure reliability in harsh industrial environments. The series covers various machine base numbers from MSK030 to MSK133, with different lengths (such as B, C, D, E, etc.) and winding versions under each base number to meet various application needs from light load high-speed to heavy load low-speed.

The motor provides various cooling methods such as natural cooling (NN), air cooling (through axial or radial fan units), and liquid cooling (FN). Among them, the liquid cooling design is specifically designed to meet the application scenarios of extremely high sustained power demand, significantly improving thermal management efficiency. All air-cooled units comply with the "Thermally Protected F" standard, eliminating the need for external motor protection switches and simplifying system design.

Core technical characteristics and data interpretation

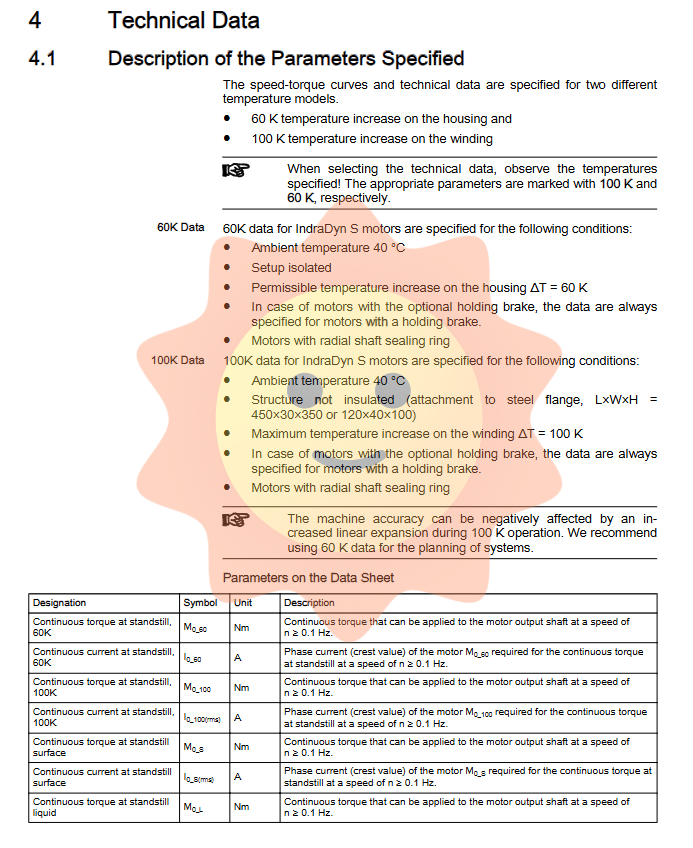

Performance parameters and working system: The motor technology data is provided based on two temperature rise models: a shell temperature rise of 60K (Δ T=60K) and a winding temperature rise of 100K (Δ T=100K). The former is suitable for motor insulation installation scenarios, while the latter is suitable for non insulation scenarios installed on steel flanges. The manual clearly states that in order to ensure the accuracy of the machine tool, it is recommended to use 60K data for system planning. The performance curve conforms to the S1 (continuous duty cycle) or S3 (intermittent cycle duty cycle) duty cycle of EN 60034-1 standard, with a typical load duration (DC) of 25% for S3.

Detailed explanation of key parameters:

Continuous locked rotor torque and current (M0, I0): Refers to the long-term output torque and corresponding effective value of phase current of the motor when the speed n ≥ 0.1 Hz. This is the benchmark for the continuous working ability of the motor.

Maximum torque and current (Mmax, Imax): The peak torque and current that a motor can output in a short period of time (about 400ms) determine its acceleration and overload capabilities.

Torque constant and back electromotive force constant (KM, KEMK): They respectively characterize the ability of current to generate torque and the ability of rotation to generate induced voltage, and are key to controller matching and voltage demand calculation.

Thermal time constant (Tth): The time required for the casing temperature to rise to 63% of the final steady-state temperature rise when the motor load reaches the allowable S1 continuous torque. For example, some models can last for more than 90 minutes under natural cooling, and require sufficient cooling after shutdown before they can be touched.

Encoder system: Provides multiple high-resolution encoder options, including single/multi turn absolute value type (Hiperface, EnDat 2.1 interface). For example, the M1 multi turn absolute value encoder can achieve absolute position recording within a mechanical rotation range of 4096 turns, and the position information is not lost after power failure, greatly simplifying system debugging and improving reliability. The position resolution depends on the number of encoder lines, controller resolution, and number of distinguishable turns.

Maintain brake: As an optional accessory, provide electromagnetic release brakes with different holding torques. Strict compliance with safety regulations is required: This brake is only used to maintain the stationary shaft when the controller is enabled to close, and cannot be used as a working brake or personnel safety brake. For vertical axes, the risk of falling must be prevented through mechanical locking, external braking/clamping devices, or sufficient weighting. The holding torque of the brake (M4) needs to be regularly checked and 'run in', which can be achieved manually or by driving the controller software function (such as IndraDrive's C3900 command).

Detailed model coding and selection process

The model code of MSK motor is the only basis for precise ordering, and its structure systematically defines all the characteristics of the motor. The basic structure of encoding is: MSK [machine base number] [length code] - [rated speed] - [cooling method] - [encoder type] - [connector direction/type] - [shaft type] [brake option] - [special design].

Machine base number and length: determine the basic size and power range of the motor.

Rated speed: a four digit number representing the typical rated speed of the winding.

Cooling methods: NN (natural cooling), FN (liquid cooling), SA (only MSK133 axial fan).

Encoder type: S1/S2/S3 (single turn absolute value) or M1/M2/M3 (multi turn absolute value), with increasing accuracy and resolution.

Connector: Specify the position and type of power and encoder interfaces (such as side A/B, left and right L/R, rotatable U, or junction box RLK for high-power motors).

Axis type: G (optical axis, recommended to use keyless coupling kit) or P (shaft with keyway).

Brake options: 0 (none), 1, 2, 3 (different holding torques).

Special designs: NNNN (standard), RNNN (improved concentricity), NSNN (explosion-proof), etc.

When selecting, it is necessary to confirm each item and refer to the "Remarks" column in the manual to understand the availability limitations of specific combinations (such as some encoders being compatible only with specific designs).

Rich attachment ecosystem

Fan Unit (LEM Series): Provides axial or radial air cooling options for motors of size 060 and above, enhancing continuous output capability. The selection table provides a detailed list of fan models that can be matched with each motor model, as well as installation methods (factory pre installed or compatible kits). The electrical connection of the fan is divided into single-phase and three-phase, with integrated thermal protection.

Sealed air connection kit: used in humid or dusty environments, to clean and dry air by inputting micro positive pressure (0.1 ± 0.05 bar) into the motor to prevent pollutant intrusion, which can approximately increase the protection level to IP67. Please note that this method cannot prevent liquids (such as open gearbox oil) that persist at the shaft seal from seeping in due to capillary action.

Gearbox: It is recommended to use optimized gearboxes such as the Rexroth GTM/GTE series. If a third-party gearbox is used, a closed lubrication system must be used to avoid long-term contact of lubricating oil with the motor shaft seal.

Connection technology and electrical interface

MSK motors use standardized electrical interfaces to ensure easy and reliable connection.

Power connectors: RLS 110 with M23 interface is commonly used for small phone numbers, RLS 1200 with M40 for medium power, RLS 130 with M58 or RLK 1200/1300 for high power. The connector includes U/V/W motor phase wires, PE grounding, temperature sensor signals (MotTemp+, MotTemp -), and brake power supply (+24VBr, 0VBr).

Encoder connector: usually RGS1000 (rotatable) or RGS1003 (fixed) with M23 interface.

Rotating connectors: RLS 1100/1200 and RGS 1000 can adjust their direction within a certain angle range (such as ± 210 °) for easy wiring. When adjusting, coupling nuts must be used and the maximum rotational torque regulations must be followed.

Liquid cooled connection: MSK071/075 uses G1/8 pipe thread, MSK101 uses G1/8, MSK133 uses G1/4. When connecting, use a joint with an axial O-ring seal, strictly follow the prescribed tightening torque (such as 14-15 Nm for G1/8) and screw in depth operation to avoid damaging the motor threads. It is recommended to design the coolant circuit as a closed system.

Key operating conditions and application precautions

Environmental conditions: Standard data is based on ambient temperature of 0-40 ° C and altitude of 0-1000m. If exceeded, performance data should be reduced according to the derating curve (fT, fH) provided in the manual. The allowable vibration and impact loads are clearly defined based on the motor model and encoder type, and continuous impact load applications need to be evaluated separately.

Installation method: Supports IM B5 (flange installation), IM V1/V3 (flange installation, axis down/up), and IM B35 (with feet). When installing IM V3 (axially), it is necessary to ensure that there is no continuous accumulation of liquid at the shaft end. When installing the foot, only radial forces perpendicular to the installation surface (± 15 °) are allowed.

Shaft and bearing load:

Axial force: Each seat number has a clear maximum allowable value (such as 60N for MSK070).

Radial force: The allowable radial force is a complex function of the average rotational speed and the distance x from the point of force application. The manual provides detailed charts for querying the allowable radial force Fradial and maximum radial failure force Fradial_max based on speed, shaft type (optical axis/keyway), and point of action position. The actual radial force must never exceed Fradial_max.

Bearing lifespan: Under rated load and environmental conditions, the design lifespan L10h is 30000 hours. If the radial force is overloaded, the bearing life will be sharply shortened according to the formula L10h-red=L10h * (Fradial/Fradial-act) ^ (10/3).

Driver component installation: Keyless connection is recommended. If gears are used, the motor performance data needs to be reduced by 20-30%, and a closed lubrication gearbox must be used. The use of extremely rigid couplings or structures that cause over positioning installation should be avoided to prevent additional bearing stress.

Cooling system design (liquid cooling): requires an external heat exchange device. The capacity of the cooling system (pumps, pipelines, heat exchangers) must be able to meet the total heat dissipation power (PV), minimum flow rate (Qmin), and pressure drop (Δ p) requirements of all parallel motors. It is recommended to use treated softened water and compatible anti-corrosion additives (such as Nalco CCL100 or TRAC100) for the coolant to form a closed cycle. It is necessary to ensure that all cooling system components have good equipotential connections.

Core Summary of Safety Regulations

The manual emphasizes safety throughout, defines a large number of terms, and provides clear guidance:

Qualified personnel: Only trained and familiar personnel with electrical hazards are allowed to operate and maintain.

Electrical safety: Before operating components with a voltage exceeding 50V, the power must be cut off and sufficient time (such as 30 minutes) must be allowed for the capacitor to discharge. The protective earth (PE) must be reliably connected, and the minimum cross-sectional area must comply with regulations.

Dangerous motion protection: Incorrect parameter settings, wiring faults, and component failures can all lead to accidental motor movement. It is not enough to rely solely on the monitoring function of the drive controller to ensure personnel safety. Additional protective measures (such as protective covers and safety fences) need to be taken at the machine level.

Magnetic field protection: Running motors generate strong magnetic fields, posing health risks to individuals wearing pacemakers, metal implants, or hearing aids. Such individuals should stay away from relevant areas.

Hot surface protection: The surface temperature of components such as motors, braking resistors, and heat sinks that are in operation or have just stopped may exceed 60 ° C and need to be fully cooled before they can come into contact.

Transportation, storage, installation, and maintenance

Transportation and storage: Avoid impact and rough handling. Long term storage requires a dry and suitable temperature environment, and regular inspections.

Installation: Mechanical installation requires ensuring that the flange or foot contact surface is flat and clean. Tighten the bolts according to the prescribed tightening torque and sequence (diagonally and gradually). Electrical connections must ensure that the connectors are clean, locked, and the cables are stress free.

Maintenance: Regularly clean the surface of the motor and fan (if installed) to ensure proper heat dissipation. Check the status of cables and connectors. The bearings are lubricated for life and do not require replenishment. To maintain the brake, it is necessary to regularly check the torque according to the aforementioned method. When a malfunction occurs, it should be diagnosed by professionals and the core components of the motor should not be disassembled by oneself.

Environmental Protection and Certification

The motor complies with environmental directives such as RoHS and should be professionally recycled and disposed of in accordance with electronic and electrical waste regulations when scrapped. The product bears the CE mark and complies with relevant EU directives. Some models have also obtained cURus (UL) certification, meeting North American market standards.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA