REXROTH IndraControl VEP Embedded Terminal Project Planning and Operation Guide

REXROTH IndraControl VEP Embedded Terminal Project Planning and Operation Guide

1. Product Overview and System Introduction

The IndraControl VEP series is a PC based machine operator terminal launched by Bosch Rexroth, suitable for monitoring, operation, and control tasks in industrial automation environments. This series includes three models: VEP 30.2, VEP 40.2, and VEP 50.2, which differ mainly in display screen size, operation mode, and interface configuration. All models adopt a unified PC box design, support PC104 expansion slots, and have good compatibility and expandability.

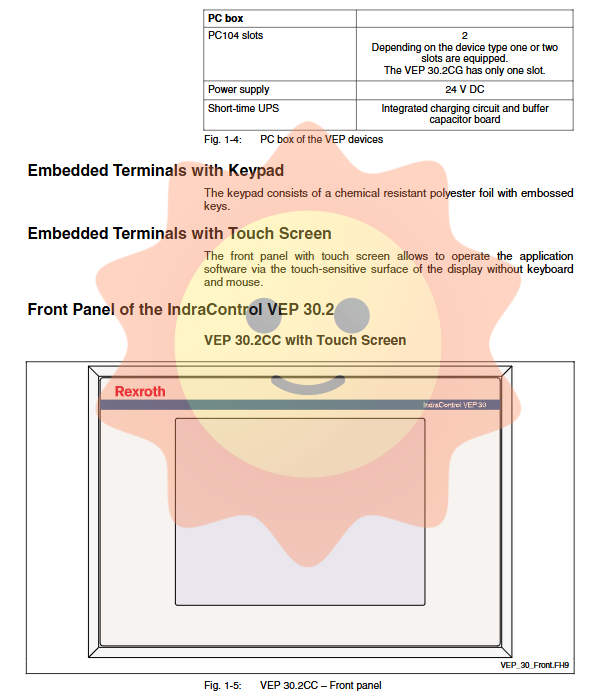

VEP 30.2 offers an 8.4-inch TFT touch screen, divided into a pure touch screen version (CC) and a version with a 5-key keyboard (CG). VEP 40.2 is equipped with a 12.1-inch touch screen, while VEP 50.2 is equipped with a 15 inch touch screen, both of which are purely touch operated. All front panels are designed in RAL 7035 light gray with a protection level of IP65 (VEP 30.2CG is IP40), suitable for environments with high hygiene requirements such as the food industry.

The device is equipped with an Intel Ultra Low Voltage Celeron 400MHz processor, 128MB memory and 128MB CompactFlash card, pre installed with Microsoft Windows CE. NET 4.2 embedded operating system, and integrated with IndraLogicWinCE soft PLC and WinStudio visual operating environment. Its 24VDC power supply has a wide input range (+19V to+30V), built-in buffer capacitor group, supports short-term UPS function, and ensures stable operation of the system under power fluctuations.

2. Technical specifications and hardware interfaces

2.1 Display and Operation Unit

VEP 30.2: 8.4-inch TFT, 800 × 600 pixels, 262K colors, touchscreen (CC type) or touch+5 key (CG type).

VEP 40.2: 12.1-inch TFT, 800 × 600 pixels, 262K colors, pure touch operation.

VEP 50.2: 15 inch TFT, 1024 × 768 pixels, 262K colors, pure touch operation.

The backlight system has an automatic dimming function, which can reduce the brightness to 50% after 5 minutes of inactivity to extend its lifespan. The lifespan of a display screen varies depending on its size: 8.4 inches for approximately 20000 hours, 12.1 inches for approximately 40000 hours, and 15 inches for approximately 30000 hours.

2.2 Core Hardware Configuration

Processor: Intel Celeron 400MHz, integrated graphics card (shared memory of approximately 8MB).

Memory: 128MB RAM, 128MB CompactFlash.

Expansion slots: up to 2 PC104 slots (VEP 30.2CG only 1).

Protection level: PC box IP20, front panel IP65 (CG type IP40).

2.3 Interface Overview

The equipment comes standard with the following interfaces:

1 x VGA external display interface (15 pin HD Sub)

2 x USB 1.1 interface (Type A)

1 x Ethernet interface (RJ45, 10/100Base-T)

1 x keyboard/mouse PS/2 interface

1 × RS232 serial interface (9-pin D-Sub)

24VDC power interface (Weidm ü ller connector, 4-pin)

The optional configuration includes a PROFIBUS DP master interface (9-pin D-Sub), supporting a maximum communication speed of 12Mbps, and comes with an RS232C diagnostic interface.

3. Safety usage regulations and electrical protection

3.1 Applicable and Not Applicable Scenarios

IndraControl VEP is designed for industrial control environments, with typical applications including handling and assembly systems, packaging and food machinery, printing and papermaking equipment, machine tools, and more. The equipment is only allowed to be used under the installation and environmental conditions (temperature, humidity, protection level, EMC, etc.) specified in the document.

It is strictly prohibited to use it in the following scenarios:

Not meeting environmental conditions (such as water, extreme temperature environment)

Special applications not explicitly approved by Bosch Rexroth

Control of protective equipment related to personal safety

3.2 Electrical safety measures

High voltage protection: All electrical components above 50V must be operated by professionals, the equipment must be reliably grounded, and copper protective wires with a cross-sectional area of not less than 10mm ² must be used.

Low voltage protection (PELV): 0-50V terminals must be connected to circuits that comply with PELV standards to ensure safe isolation from high voltage circuits.

Leakage current protection: During normal operation, the leakage current may exceed 3.5mA, so the use of residual current devices (RCD) is prohibited. Indirect contact protection should be achieved through overcurrent protection devices.

3.3 Mechanical Motion and Hazard Protection

Dangerous movement protection: It is necessary to prevent personnel from entering the range of equipment movement through higher-level monitoring equipment, safety fences, light curtains, and other measures.

Emergency stop: The emergency stop button must be installed in a location easily accessible to the operator, and its function must be verified before starting.

Vertical axis safety: After power failure, mechanical locking, external braking, and other methods must be used to prevent the axis from falling.

3.4 Electromagnetic Fields and Thermal Protection

Electromagnetic sensitive personnel: Personnel wearing pacemakers, metal implants, or hearing aids must not approach operating electrical equipment or permanent magnet motors.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA