REXROTH WE 6X series directional valve

Special variations and precautions

WE 6 6X/0... type: two position valve, dual solenoid, no positioning. The position of the valve core is undefined during power outage.

WE 6 6X/0F... type (pulse valve core): two position valve, dual electromagnet, with mechanical positioning. The valve core is alternately locked in two positions, and the electromagnet does not need to be continuously energized.

Throttle plug-in: When the flow rate that may occur during the switching process exceeds the limit of the valve's reversing ability, a throttle plug-in must be used to limit the flow rate and ensure reliable reversing.

Operation taboos:

It is strictly prohibited to operate two electromagnets simultaneously.

When using a manual operator, the fuel tank pressure should be below approximately 50 bar. When the manual operator is pressed down, it must be ensured that the electromagnet cannot be powered on for operation.

Summary of Selection and Maintenance Points

Clear requirements: Firstly, determine the required valve core function (median characteristics, number of digits), reset method, and whether manual operation is required based on the principle of hydraulic circuit.

Calculate flow rate and pressure: Based on the maximum flow rate and working pressure of the system, compare the performance curve and directional limit diagram to verify the flow capacity and directional reliability of the selected valve, paying special attention to single oil circuit conditions.

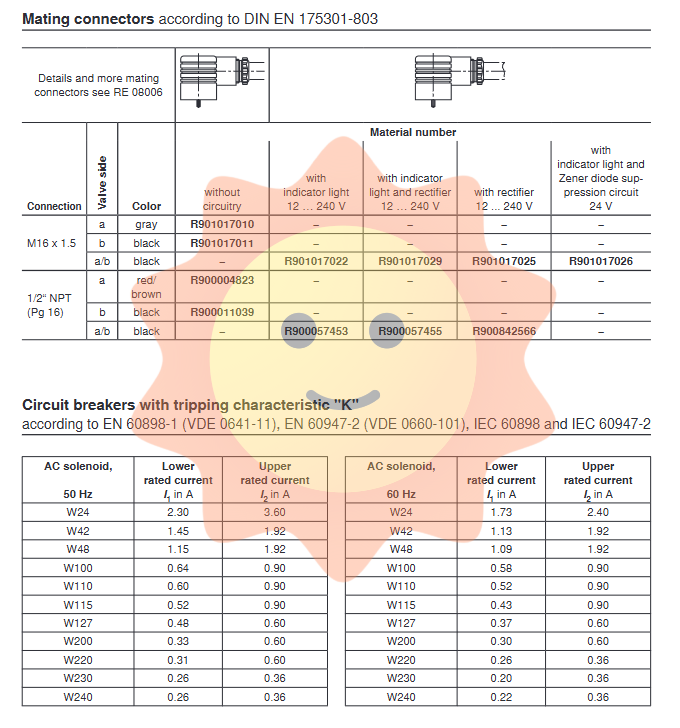

Select electrical specifications: Choose DC or AC voltage levels based on the on-site power supply situation. Consider the protection level and connection method (independent or centralized plug).

Check attachments: Select the correct base plate, installation screws, docking plugs, and seals based on the installation interface.

Comply with safety regulations: Install strictly according to the prescribed torque, ensure electrical grounding, and configure correct fuse protection as needed.

Maintenance: Regularly check the tightness and sealing of connections. When replacing the coil, ensure that the electromagnetic chamber is filled with oil. The valve itself is not repairable, and if there is an internal malfunction, it needs to be replaced as a whole.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA