REXRTOH DIAX04 Second Generation Driver Controller Application Guide

REXRTOH DIAX04 Second Generation HDD and HDS Driver Controller: Technical Analysis and Application Guide

Introduction

In the field of industrial automation and motion control, the performance and reliability of the drive controller, as the core execution unit, directly affect the operational efficiency and accuracy of the entire system. The DIAX04 second-generation HDD and HDS drive controller launched by Rexroth Indramat has become the preferred choice for many high-precision motion control systems due to its modular design, high-performance interface, and wide application adaptability. This article is based on the technical manual "DIAX04 HDD and HDS Drive Controllers 2nd Generation Project Planning Manual", which systematically outlines its technical architecture, safety specifications, electrical connections, installation points, and maintenance support, providing a comprehensive application guide for engineering and technical personnel.

System Overview and Composition Architecture

The DIAX04 system adopts a modular design concept, integrating the AC drive system into a compact drive package, which can achieve multi axis coordinated control through only one power unit. This system supports the use of MKD, MHD, 1MB, and 2AD series AC motors, and is suitable for servo and spindle drive scenarios. It is widely used in high dynamic response scenarios such as machine tools, textile machinery, printing equipment, packaging machinery, robots, and handling systems.

The main components of the system include:

Drive controller: divided into two types: HDD (dual axis fixed configuration) and HDS (configurable multi axis);

Power supply unit: such as HVE or HVR power module, providing signals and power voltage to the controller;

Additional modules: such as braking resistor HZB, capacitor module HZK, power connection module HZF, etc., used to enhance the system's energy processing capability;

Motor and feedback system: including various AC motors, encoders, and temperature monitoring devices.

Safety regulations and usage guidance

Safety is the primary principle in the design and operation of industrial equipment. The manual provides detailed safety instructions for electrical servo drive and control systems, covering the following aspects:

1. Electrical safety

High voltage protection: All electrical components above 50V must be operated by professionals after power failure, and the grounding wire must be permanently connected;

Leakage current management: Equipment leakage current may exceed 3.5mA, and copper protective wires with a cross-sectional area of not less than 10mm ² must be used;

PELV protection: All 5-50V terminals comply with the protection ultra-low voltage standard and must be connected to a safety isolated electrical circuit.

2. Sports safety

Dangerous motion protection: The driver may accidentally move due to control failures, sensor errors, or software abnormalities, and must be protected by higher-level monitoring systems or mechanical protective devices (such as guardrails, light curtains, emergency stop buttons);

Vertical axis anti fall: After power failure, the vertical axis needs to be prevented from falling through mechanical locking, external braking, or counterweight.

3. Environment and personnel safety

Electromagnetic field protection: The magnetic field generated by the motor and current carrying conductor may pose a health risk to the wearer of pacemakers, metal implants, or hearing aids, and access to relevant areas should be restricted;

Hot surface protection: During equipment operation, the casing, heat sink, and other components may experience high temperatures and need to be cooled before coming into contact;

Battery and pressure system safety: The battery must not be charged or disassembled, and the pressure system must be operated by professionals and handled properly with the working medium.

4. Usage guidelines

Applicable scenarios: Suitable for industrial automation fields such as machine tools, packaging, printing, and handling;

Prohibited use: including unverified applications such as construction cranes, manned elevators, medical equipment, explosion-proof areas, etc;

Environmental conditions: The working temperature range is+5 ° C to+45 ° C, the installation altitude does not exceed 1000 meters, and the protection level is IP10.

Driver controller configuration and modular design

The DIAX04 driver controller adopts a highly modular structure, and the basic unit is customized by inserting different functional modules for configuration. A fully configured drive includes:

Basic Unit: Provide power interface and mechanical structure;

Instruction communication module: such as SERCOS interface module DSS02.1M or analog interface module DAE02.1M;

Software module (HSM): stores firmware and driver parameters, supports hot swappable replacement;

Additional plugin module:

Digital I/O card (DEA series): supports PLC data exchange;

Measurement system interface cards (DEF, DLF, DRF, etc.): support incremental encoders, sine signal encoders, absolute value encoders, etc;

Communication cards (DAK, DAQ): support ARCNET and multi master synchronization links;

Integrated Control Card (CLC-D02.3M): Used for SYNAX multi axis synchronization applications.

Configure identification and type code

Each drive is equipped with a configuration type label, which records the type codes of the basic unit, software module, and each slot module for easy maintenance and spare parts identification. HDD02.2-W040N-HD32 is a dual axis fixed configuration type, integrating SERCOS interface and second encoder interface.

Electrical connection and signal interface

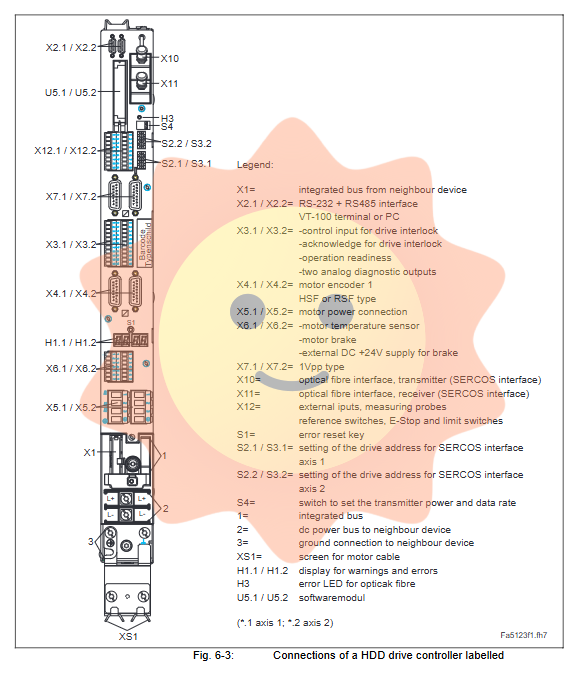

The drive controller provides rich interfaces, supporting the connection of power supply, communication, feedback, and control signals:

X1: Integrated bus connection, used for communication and power supply with adjacent units, with a maximum length of 1 meter;

X2: Serial interface (RS-232/RS-485), used for parameter setting and diagnosis;

X3: Analog output (± 10V), ready signal and start lock;

X4: Motor feedback interface (encoder 1), supporting standard encoders such as HSF/RSF;

X5: Intermediate circuit, motor and power connection, including DC bus, motor three-phase line and grounding;

X6: Maintain brake and motor temperature monitoring;

X7.1/X7.2: Second encoder interface (1Vpp sine signal), used for high-precision position detection;

X10/X11: ERCOS fiber optic interface, supports 2M/4M baud rates, complies with IEC/EN 61491 standard;

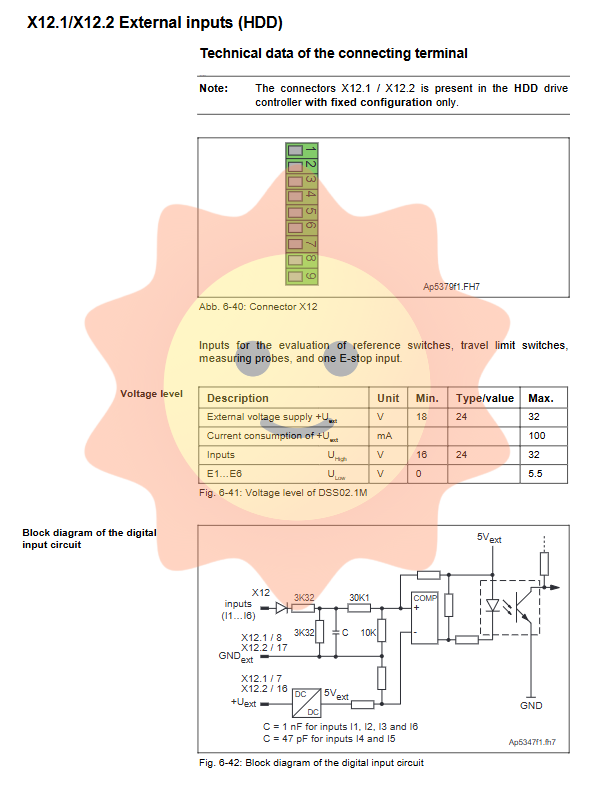

X12.1/X12.2: External digital input, used for reference switches, limit switches, emergency stop signals, etc.

Wiring suggestions

Signal lines and power lines should be arranged separately, with a minimum spacing of 100mm or isolated using metal wire trays;

The maximum length of motor cable and feedback cable is 75 meters (ambient temperature ≤ 40 ° C);

The shielding layer should be grounded at the controller end, using original cables or shielded cables that comply with specifications.

Control cabinet design and heat dissipation management

1. Mechanical installation

Use SUP-M01-HD to install the guide rail vertically, with the motor interface facing downwards;

The driver should be arranged close to the power unit, and when the total power is greater than 36kW, it should be evenly distributed on both sides;

The guide rail needs to be fixed every two slots with M5 screws and ensure good electrical contact with the mounting plate.

2. Heat dissipation calculation

Driver power loss includes control unit loss, configuration module loss, and power segment loss. The manual provides loss curves for various models of drivers at different currents. Users can calculate the total loss based on the actual operating current and design corresponding heat dissipation schemes. For example, the total loss of a four axis system may be close to 2kW, which needs to be naturally dissipated through the control cabinet or discharged through the installation of a cooling system.

3. Use of cooling system

The set temperature of the cooling system shall not be lower than 40 ° C to prevent condensation inside the cabinet;

The air outlet should not be aligned with electronic devices to prevent condensation from falling;

After shutdown, the cooling system should continue to operate until the temperature inside and outside the cabinet is balanced.

4. EMC protection measures

The motor cable must be shielded and grounded at the controller end;

Install interference suppression filters at the power supply inlet end;

Inductive loads (contactors, relays) should use RC modules or freewheeling diodes to suppress interference.

Debugging, diagnosis, and maintenance

1. Debugging and parameter settings

Before the first use of the drive, it needs to be parameterized through software (such as DriveTop), which can be connected to a PC through RS-232/RS-485 interface or SERCOS interface. The software module HSM supports parameter storage and migration, and can quickly restore configuration when replacing the drive.

2. Diagnostic function

The driver outputs error messages through the front panel status indicator H1 and SERCOS interface;

Analog diagnostic output AK1/AK2 can output internal signals (such as current and speed) for oscilloscope monitoring;

The ready signal Bb can be used for system level status monitoring.

3. Service and Support

Rexroth Indramat provides a global service network, including:

Technical Support Hotline (Germany Headquarters:+49 9352 40-4894);

7 × 24-hour service hotline (mobile phone);

Sales and service centers in various regions (covering Europe, America, Asia, etc.).

Maintenance and repair should be carried out by certified personnel, and re debugging is required after replacing the unit. The driver has undergone high voltage and insulation testing in accordance with DIN VDE 0160.

Typical application scenarios

The DIAX04 driver is suitable for the following high dynamic, multi axis cooperative control systems:

CNC machine tools: spindle drive, feed axis control;

Packaging machinery: positioning, sealing, labeling;

Printing equipment: drum synchronization, tension control;

Robots: joint drive, trajectory planning;

Handling system: positioning handling, synchronous conveying.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA