REXRTOH EcoDrive 03 Drive Controller

Detailed Explanation of Electrical Connections: System Integration from Power Supply to Signal

Correct wiring is the cornerstone of stable system operation. EcoDrive 03 provides clear and functional interfaces.

1. Power supply and control voltage connection (X5, X1):

Main power supply (X5): Connect single-phase or three-phase AC power supply (L1, L2, L3) and DC bus (L+, L -). DC bus can be used for parallel connection of multiple drivers to achieve energy sharing. Cables with sufficient cross-sectional area (maximum 25mm ²) must be used and tightened with the specified torque (2.5-3.0 Nm).

Control voltage (X1): Provides 24V DC power supply for controller logic circuits, interfaces, and external sensors. It is allowed to provide power through the X1 terminal with a maximum current of 10A. Loss of control voltage will cause the motor to slide freely and must be prevented through peripheral safety measures.

2. Motor and feedback connection (X5, X6):

Motor power line (X5): Connect the U, V, and W phases of the servo motor. To ensure electromagnetic compatibility (EMC), shielded motor cables must be used, and the length should not exceed 75 meters at the standard 4kHz switching frequency (shortened at higher frequencies).

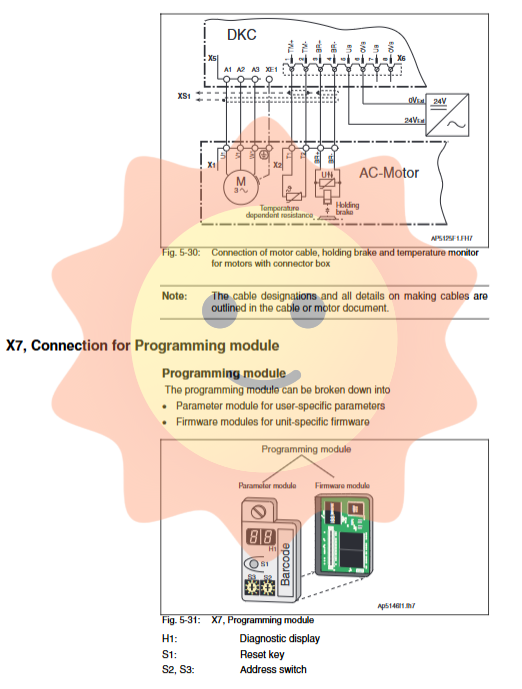

Motor temperature monitoring (X6: TM+, TM -): used to read the PTC/NTC thermistor signals built into the motor to achieve overheating protection. Only applicable to Rexroth original motors.

Motor holding brake (X6: BR+, BR -): controls the built-in holding brake of the motor. This brake is only used for holding and not for safety braking. Its power supply needs to be independent of the control voltage, and the maximum switching current varies from 2A to 4A depending on the model.

3. Control and communication interfaces (X1, X3, etc.):

Drive Enable (RF) and Drive Stop (AH): Digital input signals used to quickly activate or safely stop the drive shaft.

Ready contact (Bb): A relay contact output indicating that the driver is ready to connect to the main power supply. It must be integrated into the main power control circuit, otherwise it may cause damage.

Communication interface: SERCOS, PROFIBUS-DP and other modules can be selected according to the model to achieve data exchange with the upper layer controller.

4. Shielding and grounding (XS1, XS2, XS3, XE1, XE2):

Shielded connection points (XS1-3): used for centralized connection of shielding layers of motor cables, control cables, and communication cables, ensuring 360 ° large-area contact, which is the key to suppressing electromagnetic interference.

Protective Grounding (XE1, XE2): Used for protective grounding on the motor side and power side respectively, it must be reliably connected to the cabinet grounding bar using a ≥ 10mm ² wire.

Installation and environmental requirements

1. Control cabinet design:

The driver should be installed vertically on a 35mm top cap guide rail that complies with EN 60715 standard.

Ensure good ventilation inside the cabinet to avoid heat accumulation. When using a cooling unit, it is necessary to prevent condensed water from falling onto electronic devices.

Signal lines and power lines must be routed separately, with a minimum spacing of 30cm, and should be crossed at right angles as much as possible.

2. Electrostatic protection (ESD):

All electronic components are sensitive to static electricity. Anti static wristbands should be worn during operation, and circuit boards should be stored in anti-static packaging.

3. Touch protective cover:

After the wiring is completed, the touch protection cover provided with the equipment must be installed to prevent accidental contact with the high-voltage terminals. The openings on the protective cover should be as small as possible.

Debugging, maintenance, and fault prevention

1. Parameter setting: Parameterization can be done through the programming module (X7) on the front panel or the upper software. The programming module includes diagnostic LEDs, reset keys, and address switches.

2. DC bus discharge: After the system is powered off, the internal capacitors need time to discharge. The manual emphasizes that even for user level discharge circuits, a multimeter must be used to verify that the voltage is below 50V before touching any terminals.

3. Fault diagnosis: The LED indicator lights on the driver front panel and programming module can provide rich status and fault information, and combined with the diagnostic code table in the manual, the problem can be quickly located.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA