REXRTOH EcoDrive 03 Drive Controller

Rexroth EcoDrive 03 Drive Controller: A Comprehensive Guide to Installing and Applying High Performance Motion Control

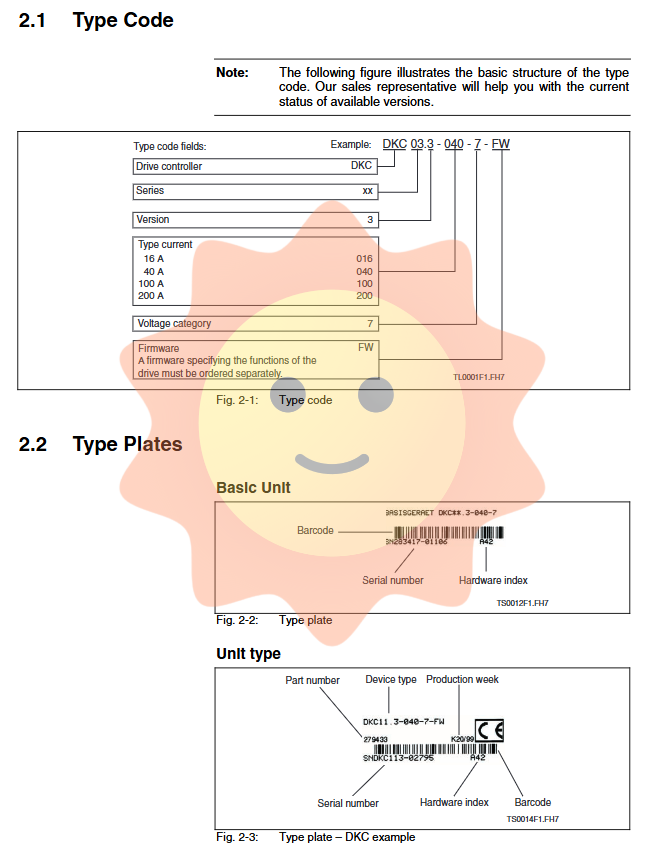

In the field of industrial automation and precision motion control, the performance, reliability, and safety of the drive controller directly determine the operational quality of the entire system. The EcoDrive 03 series drive controllers launched by Bosch Rexroth, especially the DKC03-040, DKC03-100, and DKC03-200 models, represent its maturity and innovation in servo drive technology. This article is based on the official technical manual, systematically interpreting the technical specifications, safety standards, installation and wiring points, and usage precautions of this series of controllers, providing a comprehensive and in-depth operation guide for engineering design, installation, commissioning, and maintenance personnel.

Product Overview and Positioning

EcoDrive 03 is a driver series designed by Rexroth to meet mid to high performance servo applications, suitable for various industrial machinery, machine tools, automated production lines, and other occasions. The DKC03 series is its core product, with the following typical features:

Comprehensive power coverage: providing three current levels of 040 (40A), 100 (100A), and 200 (200A), suitable for driving needs of servo motors ranging from small to large sizes.

High performance control: Supports servo control with high dynamic response, with a maximum output frequency of 1000Hz, meeting the requirements of precision positioning and synchronous motion.

Multi interface compatibility: Supports SERCOS, analog, parallel interfaces, and multiple fieldbuses (such as PROFIBUS-DP), making it easy to integrate into control systems of different architectures.

Compact and sturdy design: Adopting a modular structure, it meets the vibration, impact, and temperature requirements of industrial environments, and the protection level is suitable for installation inside control cabinets.

Core security standards: mandatory reading guidelines before operation

When using high-voltage and high-power driving equipment, safety is always the top priority. The manual extensively emphasizes the safety instructions that must be followed:

1. Electrical safety:

High voltage hazard: The main circuit voltage of the controller can reach 480V AC, and the DC bus voltage can reach up to 800V DC. Before operation, the power must be cut off and wait for at least 30 minutes to ensure that the DC bus capacitor discharges to a safe voltage (<50V) or below.

Grounding protection: The equipment grounding wire (PE) must use a copper wire with a cross-sectional area of not less than 10mm ², and ensure continuous grounding from the power supply to the motor throughout the entire process to discharge leakage currents up to>3.5mA.

Prohibit the use of residual current devices (RCD): Due to the high-frequency leakage current generated by the driver, circuit breakers or fuses should be used for overcurrent protection.

2. Mechanical and sports safety:

Dangerous motion protection: Driver failure, parameter errors, or sensor failures may cause unexpected motor movement. The safety isolation between personnel and the movement area must be achieved through peripheral safety circuits such as safety relays, light curtains, and protective barriers.

Vertical axis anti fall: The built-in motor brake or driver controlled brake cannot be used to ensure personal safety. The vertical axis must be equipped with additional mechanical locking, external braking or balancing devices to prevent falling after power failure.

Emergency stop function: The emergency stop button must be installed within reach of the operator and its function must be verified before starting.

3. Environment and personal safety:

High temperature surface: The temperature of the motor, driver, and reactor casing may exceed 60 ° C during operation, and the cooling time may last up to 140 minutes. Wear protective gloves when in contact.

Electromagnetic field effects: Strong electromagnetic fields may interfere with pacemakers, metal implants, or hearing aids. Relevant personnel should avoid approaching areas where electrical equipment is in operation.

4. Compliant use: The product can only be used for the application scenarios specified in the technical documentation and must be operated by trained and qualified personnel.

Technical specifications and mechanical dimensions

The key rated data of DKC03 series drives are shown in the following table:

Parameter symbol unit DKC03.3-040 DKC03.3-100 DKC03.3-200

Rated input voltage V V AC 200... 480 (single-phase/three-phase) 200... 480 (single-phase/three-phase) 200... 480 (single-phase/three-phase)

Maximum input current I2 L_cont A 16 40 70

Maximum output current I2 out_max A 40 100 200

Maximum output frequency f_out Hz 1000 1000 1000

Control voltage U-N 3 V DC 24 24 24

Working temperature: Tmax ° C 45 (rated), 55 (rated), 55 (rated), 45 (rated), 55 (rated), 55 (rated)

Power consumption (continuous) P_Diss_cont W 180 420 960

Weight m kg 5.7 9.7 19.5

Dimensions (H × W × D) - mm 360 × 65 × 261 360 × 105 × 261 360 × 230 × 261

Installation spacing requirements: To ensure sufficient heat dissipation, at least 150mm of space should be reserved at the top of the controller, and at least 80mm of space should be reserved at the bottom. When installing multiple drives side by side, it is important to ensure that the intake temperature does not exceed the allowable value.

Detailed Explanation of Electrical Connections: System Integration from Power Supply to Signal

Correct wiring is the cornerstone of stable system operation. EcoDrive 03 provides clear and functional interfaces.

1. Power supply and control voltage connection (X5, X1):

Main power supply (X5): Connect single-phase or three-phase AC power supply (L1, L2, L3) and DC bus (L+, L -). DC bus can be used for parallel connection of multiple drivers to achieve energy sharing. Cables with sufficient cross-sectional area (maximum 25mm ²) must be used and tightened with the specified torque (2.5-3.0 Nm).

Control voltage (X1): Provides 24V DC power supply for controller logic circuits, interfaces, and external sensors. It is allowed to provide power through the X1 terminal with a maximum current of 10A. Loss of control voltage will cause the motor to slide freely and must be prevented through peripheral safety measures.

2. Motor and feedback connection (X5, X6):

Motor power line (X5): Connect the U, V, and W phases of the servo motor. To ensure electromagnetic compatibility (EMC), shielded motor cables must be used, and the length should not exceed 75 meters at the standard 4kHz switching frequency (shortened at higher frequencies).

Motor temperature monitoring (X6: TM+, TM -): used to read the PTC/NTC thermistor signals built into the motor to achieve overheating protection. Only applicable to Rexroth original motors.

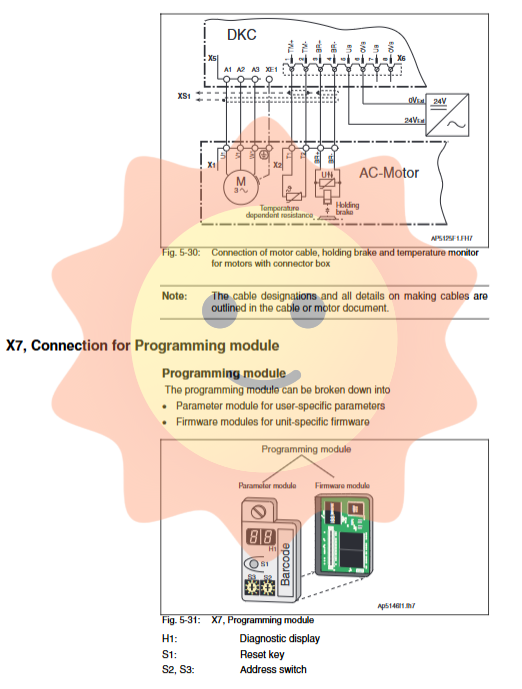

Motor holding brake (X6: BR+, BR -): controls the built-in holding brake of the motor. This brake is only used for holding and not for safety braking. Its power supply needs to be independent of the control voltage, and the maximum switching current varies from 2A to 4A depending on the model.

3. Control and communication interfaces (X1, X3, etc.):

Drive Enable (RF) and Drive Stop (AH): Digital input signals used to quickly activate or safely stop the drive shaft.

Ready contact (Bb): A relay contact output indicating that the driver is ready to connect to the main power supply. It must be integrated into the main power control circuit, otherwise it may cause damage.

Communication interface: SERCOS, PROFIBUS-DP and other modules can be selected according to the model to achieve data exchange with the upper layer controller.

4. Shielding and grounding (XS1, XS2, XS3, XE1, XE2):

Shielded connection points (XS1-3): used for centralized connection of shielding layers of motor cables, control cables, and communication cables, ensuring 360 ° large-area contact, which is the key to suppressing electromagnetic interference.

Protective Grounding (XE1, XE2): Used for protective grounding on the motor side and power side respectively, it must be reliably connected to the cabinet grounding bar using a ≥ 10mm ² wire.

Installation and environmental requirements

1. Control cabinet design:

The driver should be installed vertically on a 35mm top cap guide rail that complies with EN 60715 standard.

Ensure good ventilation inside the cabinet to avoid heat accumulation. When using a cooling unit, it is necessary to prevent condensed water from falling onto electronic devices.

Signal lines and power lines must be routed separately, with a minimum spacing of 30cm, and should be crossed at right angles as much as possible.

2. Electrostatic protection (ESD):

All electronic components are sensitive to static electricity. Anti static wristbands should be worn during operation, and circuit boards should be stored in anti-static packaging.

3. Touch protective cover:

After the wiring is completed, the touch protection cover provided with the equipment must be installed to prevent accidental contact with the high-voltage terminals. The openings on the protective cover should be as small as possible.

Debugging, maintenance, and fault prevention

1. Parameter setting: Parameterization can be done through the programming module (X7) on the front panel or the upper software. The programming module includes diagnostic LEDs, reset keys, and address switches.

2. DC bus discharge: After the system is powered off, the internal capacitors need time to discharge. The manual emphasizes that even for user level discharge circuits, a multimeter must be used to verify that the voltage is below 50V before touching any terminals.

3. Fault diagnosis: The LED indicator lights on the driver front panel and programming module can provide rich status and fault information, and combined with the diagnostic code table in the manual, the problem can be quickly located.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA