COTEK SD Series Pure Sine Wave Inverter

Connection specification: When connecting the battery, the red terminal is the positive pole (+) and the black terminal is the negative pole (-). All connections must be firm, with a recommended torque of 3-3.5 N · m. There may be small sparks during the connection, which is a normal phenomenon of internal capacitor charging.

Grounding requirement: The inverter housing must be reliably connected to the vehicle chassis or grounding system using at least 8 AWG (approximately 10mm ²) wires, otherwise there may be a risk of electric shock.

3. Key points for communication wiring installation:

The inverter provides two connection methods: hard wired terminals and output sockets, which are connected in parallel internally. When the load current approaches or exceeds the rated current of the socket, it is strongly recommended to use hard wired terminals.

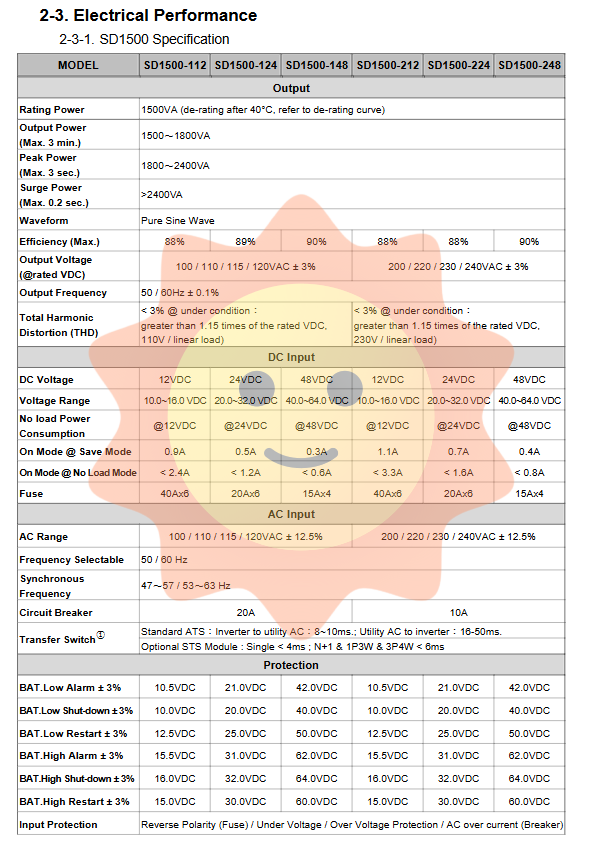

The communication input/output wiring should comply with local electrical regulations, and it is recommended to be operated by professional electricians. When wiring, it is necessary to distinguish between live wire (L), neutral wire (N), and ground wire (GND). For the SD1500 model, special attention should be paid to the setting of its neutral grounding option, as incorrect settings may lead to safety risks.

Advanced Features: Parallel Mode and Multiphase System Construction

The most striking feature of the SD series is its powerful parallel capability, which can not only be used for power expansion, but also for building complex multiphase power supply systems.

1. Parallel configuration steps:

Pre setting: Set all main switches of the inverters to be connected in parallel to "OFF". Set the terminal resistance through the parallel jumper on the green terminal: the first and last devices in the parallel system need to set the jumper to "ON" and the intermediate device to "OFF".

Parameter synchronization: Set the DIP switches (S1-S3) of all devices to the same output voltage and frequency.

Physical connection:

Use RJ-45 Ethernet cable (parallel connection cable) to sequentially connect the CAN1 port and CAN1 port (or CAN2 and CAN2) of each device in series.

Connect the DC input terminals (positive and negative) of each device in parallel to the battery.

Connect the AC output terminals (live wire and live wire, neutral wire and neutral wire) of each device in parallel.

System architecture: The system adopts a master-slave architecture and supports automatic election of master devices. Users only need to set the parameters of the master device, and the slave devices will automatically synchronize. By using different combinations of DIP switches S4-S6, the roles of devices in parallel systems can be configured (such as master device, 0 ° slave device, 120 ° slave device, etc.).

2. Multiphase system applications:

Single phase three wire system (1 Φ 3W): By setting two inverters to 0 ° main equipment and 180 ° slave equipment in parallel, a set of single-phase three wire outputs with doubled voltage (such as L1-L2 voltage being twice the L-N voltage) can be obtained, which is suitable for situations where higher line voltage is required.

Three phase four wire system (3 Φ 4W): By setting three inverters in parallel at 0 ° (L1), -120 ° (L2), and+120 ° (L3), a complete three-phase four wire power supply system can be constructed. For example, when each inverter output is set to 100V/50Hz, a three-phase balanced power supply with a phase voltage of 100V and a line voltage of approximately 173V can be obtained, which can directly drive three-phase industrial equipment.

This flexibility enables the SD series to go beyond the scope of ordinary vehicle inverters and become an ideal solution for small commercial, off grid energy stations, and special equipment power supply.

Operation, Control, and Communication

1. Front panel and status indicator:

The front panel of the inverter is equipped with a power switch (ON/OFF/REMOTE), LED status indicator lights, and an 8-bit DIP switch.

LED indicator light: Through different flashing modes of green, orange, and red LEDs, the device status is intuitively displayed, such as normal operation, energy-saving mode, bypass mode, undervoltage/overvoltage warning, overheating, overload, and various faults.

DIP switch: used for basic settings, including output voltage (100/110/115/120VAC or corresponding 220V range), output frequency (50/60Hz), energy-saving mode threshold (4% -8% rated power), and phase role in parallel systems.

2. Remote control and communication interface:

LCM port: used to connect LCD remote monitoring panels (such as CR-6, CR-8, CR-10) to achieve remote power on/off, parameter setting, and status monitoring.

RS-232 port: Provides serial communication capability with the computer. By sending specific ASCII code commands (ending in CR/LF), users can remotely query device status (such as input/output voltage and current, output power, frequency), control output switches, and enter the settings menu to adjust up to 19 advanced parameters, including various protection voltage thresholds, synchronous frequency windows, energy-saving mode parameters, LCD display settings, buzzer alarm options, and interface language.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands