Siemens SENTRON 5SY6106-7 miniature circuit breaker

Technical Analysis and Application Guide for Siemens 5SY6106-7 Miniature Circuit Breaker

Product Overview and Market Positioning

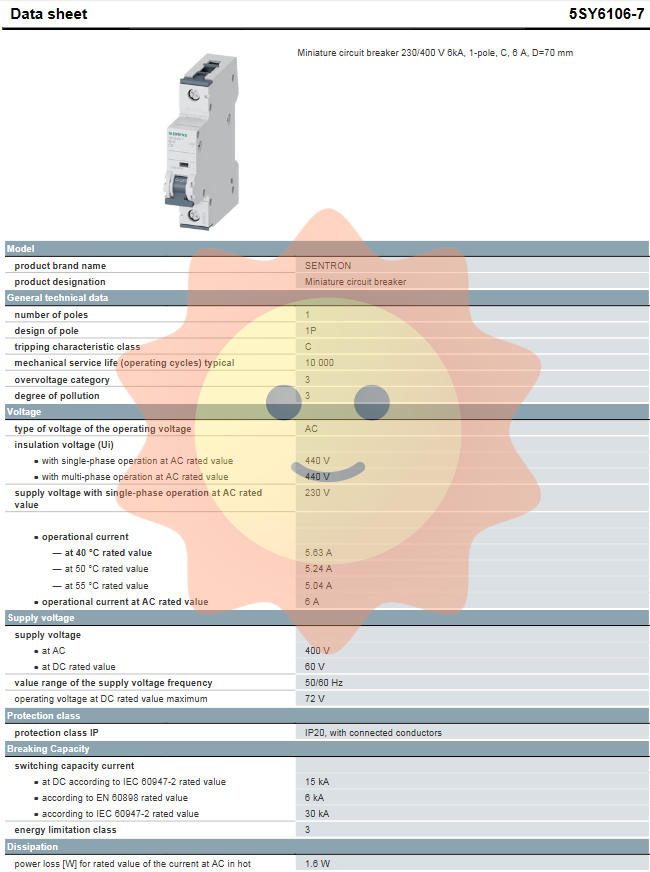

The Siemens SENTRON series 5SY6106-7 miniature circuit breaker is a critical protection device designed specifically for low-voltage distribution systems, suitable for circuit protection and control in industrial, infrastructure, and commercial buildings. This product complies with multiple international standards such as IEC/EN 60898-1, IEC/EN 60947-2, and UL 1077, and features high reliability, compact structure, and flexible configuration. It is widely used for overload and short circuit protection of lighting, sockets, motors, and various electrical equipment.

As a miniature circuit breaker with single pole (1P) C-type tripping characteristics, 5SY6106-7 provides a breaking capacity of up to 30kA (IEC 60947-2) under rated current conditions of 6A. Its excellent current limiting performance (energy limit level 3) can effectively suppress the impact of fault current on the system and ensure the safety of electrical equipment and personnel.

Core technical parameters and performance analysis

2.1 Electrical parameters and working conditions

Rated voltage: AC 230/400V, DC 60V (maximum operating voltage 72V), suitable for single-phase or multi-phase systems;

Rated current: 6A, with capacity reduction characteristics at different ambient temperatures:

At 40 ° C: 5.63A

At 50 ° C: 5.24A

At 55 ° C: 5.04A

Insulation voltage: 440V, meeting the requirements of overvoltage category III;

Pollution level: Level 3, suitable for higher pollution conditions in industrial environments;

Protection level: IP20 (after wiring), providing basic touch protection.

2.2 Breaking and current limiting performance

This circuit breaker has multiple breaking capacity certification:

IEC 60947-2:30kA(AC)

EN 60898:6kA(AC)

IEC 60947-2(DC):15kA

UL 1077 / CSA C22.2 No.235:5kA(AC)

Its energy limitation level is level 3, which means that it can quickly limit and disconnect under short-circuit conditions, significantly reducing the thermal effects and electrical stress of fault currents, and protecting downstream lines and equipment.

2.3 Mechanical and Life Characteristics

Mechanical lifespan: Typical value of 10000 operations, ensuring reliability in frequent switching situations;

Installation method: Supports DIN rail (TH35-7.5/15) installation and can be flexibly integrated into the distribution box;

Compact size: occupying only one module width (18mm), height 90mm, depth 76mm, installation depth 70mm;

Lightweight: about 150.1g, easy to transport and install.

Key points of structural design and installation

3.1 Terminal and Wiring Capability

5SY6106-7 adopts a combination terminal design with both top and bottom, supporting multiple wire types:

Wire cross-sectional area:

Solid wire: 0.75-35mm ²

Stranded wire: 0.75-35mm ²

Thin stranded wire (with end treatment): 0.75-25mm ²

AWG range: 18-4

Tightening torque: 2.5-3.5 N · m (22-31 lbf in)

The incoming direction of the power supply can be freely selected for easy on-site wiring. The terminal design has good contact pressure and anti loosening characteristics, ensuring the reliability of electrical connections for long-term operation.

3.2 Environmental adaptability and safety characteristics

Working temperature range: -25 ° C to+55 ° C, suitable for most indoor and outdoor environments;

Humidity tolerance: up to 95% relative humidity (at 55 ° C);

Vibration resistance: in accordance with IEC 60068-2-6, suitable for situations where mechanical vibration exists;

Environmentally friendly design: The product meets the requirements of halogen free and silicon free, and supports sealed design, suitable for sensitive environments;

Scalability: Supports the installation of auxiliary contacts, undervoltage release devices, and other accessories to enhance control functionality.

Release characteristics and application selection guide

4.1 Analysis of C-type release curve

5SY6106-7 adopts a C-type tripping characteristic, with an instantaneous tripping current range of 5-10 times the rated current (i.e. 30-60A), suitable for starting current surge protection of common inductive loads (such as small motors, transformers, lighting ballasts, etc.), avoiding false tripping while ensuring short-circuit protection sensitivity.

4.2 Selection and System Matching Suggestions

Load type recognition: For resistive loads (such as heating equipment), type B can be selected; For inductive loads, it is recommended to choose type C;

Environmental temperature correction: In high-temperature environments, higher rated current specifications should be selected according to the derating curve;

Verification of breaking capacity: Select circuit breakers with an expected short-circuit current of ≥ Icn based on the installation point;

Selective cooperation: Compare the time current curve with the higher-level circuit breaker or fuse to ensure selective tripping in case of a fault.

4.3 Typical application scenarios

Industrial control cabinet: provides branch protection for PLCs, sensors, and low-power drives;

Building electrical: terminal protection for lighting circuits, socket circuits, air conditioning units, etc;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA