SERVOSTAR ® Usage of CD-LITE servo amplifier

SERVOSTAR ® CD-LITE servo amplifier

Basic information of the document

Product positioning: SERVOSTAR ® CD-LITE is an economical digital servo amplifier launched by Danaher Motion Kollmorgen. It focuses on current loop applications, supports full digital current and speed loop control, does not require potentiometer adjustment, and has digital parameter storage without drift. It is compatible with various brushless motors.

Version compatibility: The document has been revised to version 2 of 2003, corresponding to firmware version 1.1.0, and needs to be paired with MOTIONLINK 4.4.3 software (the two must match the version and cannot be mixed); Historical versions include version 1 from 2001 (firmware 0.1.2).

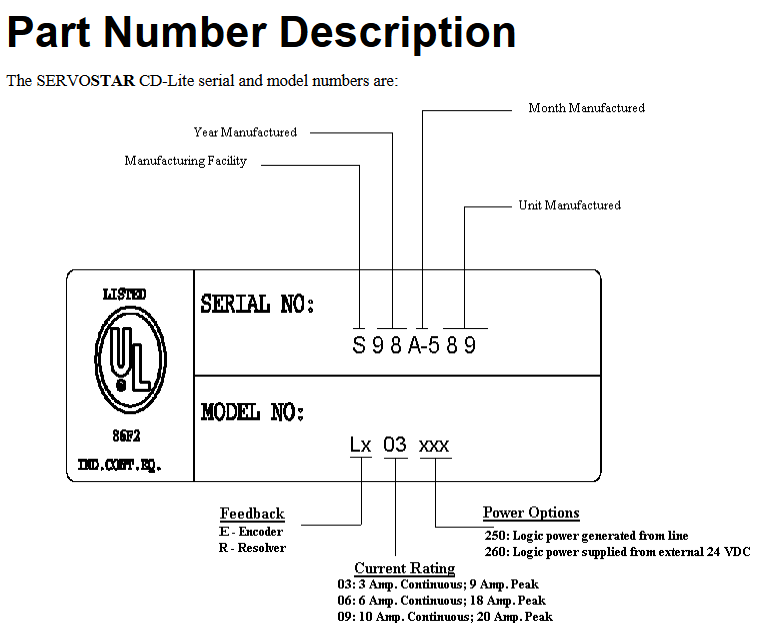

Core identification: The product model includes current level (03=3A continuous/9A peak, 06=6A continuous/18A peak, 09=10A continuous/20A peak), logic power mode (250=line generation, 260=external 24V power supply), and feedback type (E=encoder, R=rotary transformer, rotary transformer only supports external 24V logic power supply).

Product Core Features

(1) Basic functions

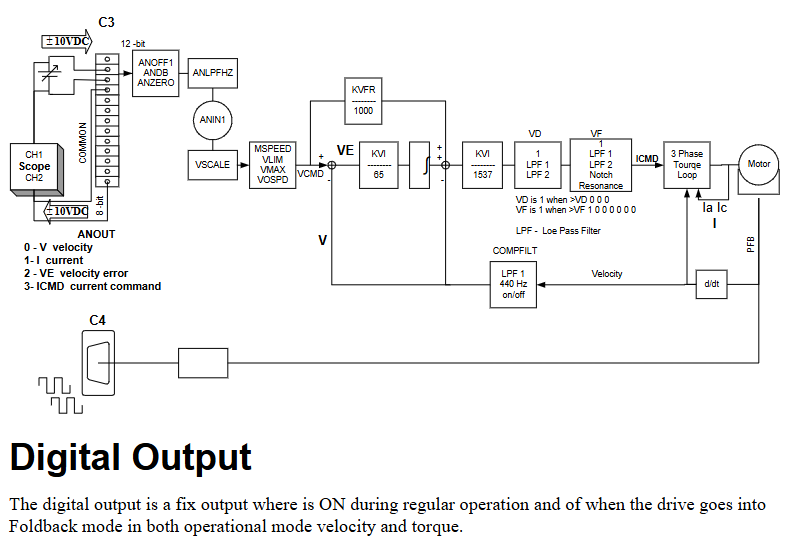

Control mode: Supports speed loop (OPMODE=1, ± 10V analog given), torque/current loop (OPMODE=3, ± 10V analog given), PWM switching frequency up to 16kHz.

Feedback support: Incremental encoder (A/B/Z+Hall, A/B+Hall), rotary transformer (requires external 24V logic power supply), Hall only (sine commutation/six step commutation), supports encoder equivalent output (EEO, orthogonal signal, up to 3MHz).

Power and protection: continuous current 3/6/10A, peak current is 3 times the continuous value; Equipped with overvoltage, undervoltage, overcurrent, overtemperature (driver/motor), feedback disconnection, and I ² t turn back protection (to prevent driver overheating).

(2) Hardware and Design

Isolation design: Electronic components are fully isolated, and the logic power supply can be generated by circuit or external 24V power supply, with strong anti-interference ability.

Communication interface: Only supports RS-232 serial port (for PC debugging or Personality Module configuration), baud rate 9600/19200bps (set by DIP switch 6), no extended communication interface (different from the full version SERVOSTAR CD).

I/O configuration: C3 interface includes differential analog input (ANIN1, 12 bit AD, 250 μ s/62.5 μ s sampling rate), remote enable input (REMOTE, 12-24V optocoupler isolation), fault relay output (RELAY, configurable "driver ready"/"driver enable" mode), 2 hardware limit switch inputs (only available for speed loop), and 1 analog output (ANOUT, 8-bit, monitoring speed/current/speed error/current command).

System startup and debugging

(1) Hardware and software requirements

PC configuration: IBM compatible (Pentium and above), 16MB memory, Windows 95/98/NT 4.0 (SP3)/2000, CD-ROM drive, 1 serial port (COM1-COM4).

Software installation: Automatically run (or manually execute "D: AUTORUN. EXE") through the MOTIONLINK installation disc, with the program path being "Start - Programs - SERVOSTAR MOTIONLINK".

(2) Debugging process

Communication settings: The RS-232 protocol has 8 data bits, 1 stop bit, no checksum, and the baud rate matches the DIP switch settings; The parameters are stored in EEPROM (non-volatile), and after modification, the "SAVE" command must be executed to save them to EEPROM, otherwise they will be lost due to power failure.

Quick Startup Wizard:

Driver configuration: Select bus voltage (VBUS) and monitor DIP switch status in real-time (address, baud rate, etc.);

Motor configuration: Select the model (such as GOLDLINE XT series) from the MOTIONLINK motor database, click "To Drive" to download parameters, and contact the manufacturer for unknown motors;

Mode configuration: Select control mode (speed/torque), torque mode does not require tuning, speed mode requires adjustment of PDFF parameters (VF/VD/COMPFILT);

Backup and Startup: Parameters can be saved as SSV file (for multi drive configuration), enter the main interface after completion.

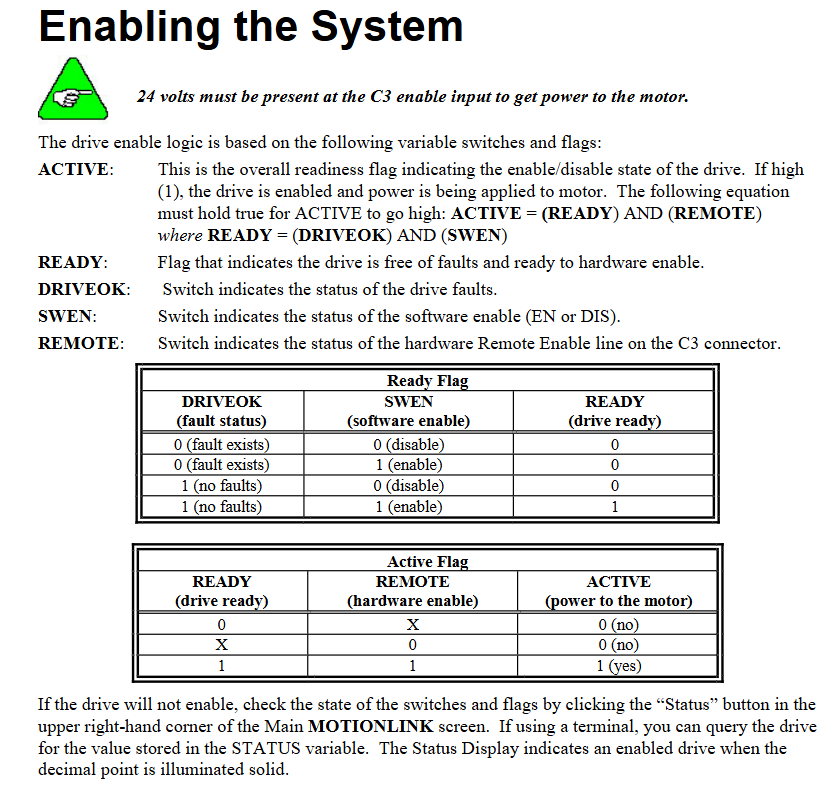

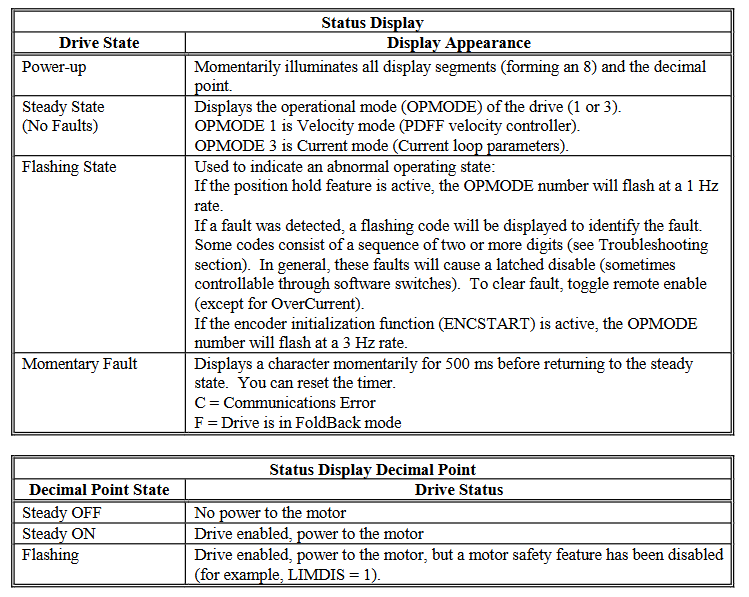

Driver Enable: Must meet the requirement of "ACTION=READY × REMOTE", where "READY=DRIVE OK × SWEN" (DRIVE OK=no fault, SWEN=software enable, REMOTE=hardware enable), and the decimal point in the status bar should remain lit after enabling.

Feedback system and control loop

(1) Feedback type details

Key parameter limitations and characteristics of feedback types

Incremental encoder resolution MENCRES (number of lines), can be scaled by ENCOUTO (1/2/4/8/16 times), cable length ≤ 15m, maximum input frequency 3MHz (before orthogonal)/12MHz (after orthogonal), supports wire breakage detection

The fixed resolution of the rotary transformer is 4096, and the RDRES automatically adjusts with speed (such as RDRES=1665536 counts/revolution when VLIM<1500RPM). The cable length is ≤ 22.9m (recommended shielded twisted pair), and the accuracy is composed of R/D converter (4 arcminutes), mechanical installation (8 arcminutes), etc. The total error is ≤ 19 arcminutes

Only Hall sine commutation (MENCTYPE=5) or six step commutation (DIP switch 2 set to ON, MENCTYPE=10) relies on Hall signals to generate commutation waveforms, which are updated once per Hall switch, with low accuracy and suitable for simple scenarios

(2) Control loop principle

Current loop: fully digital pole configuration, sampling rate of 16kHz (62.5 μ s), converts current command into three-phase PWM signal, includes adaptive gain compensation for nonlinearity, monitors A/C phase current (IA/IC) and calculates equivalent current (I).

Reversing loop: With a frequency update of 16kHz, it converts single-phase signals into three-phase position modulated sine waves and supports the patented technology of "torque angle lead". It needs to be aligned with the back electromotive force of the motor (feedback alignment is crucial).

Speed loop: Sampling rate 4kHz, using PDFF (pseudo differential feedforward) algorithm, calculating actual speed through feedback, filtering the difference between the actual speed and the instruction speed, and sending it to the commutation loop, suitable for high-precision speed control.

Fault handling and maintenance

(1) Fault classification and troubleshooting

Fatal malfunction (driver disabled, some require power-off reset):

Overheating (t): Overload, fan failure, or power level damage, reset after cooling;

Overvoltage (o): During the regeneration process, the bus voltage is too high. Check the braking resistance or deceleration curve;

Overcurrent (P): Power level surge current, requiring power-off reset, checking for motor short circuit or power level fault;

Feedback fault (r1/r2/r4/r6): Rotary transformer/encoder disconnected or illegal Hall combination, check the feedback cable.

Non fatal fault (disabled drive, can be reset by enabling):

Undervoltage (u): Input voltage too low or power failure, check power supply;

Motor overheating (H): The motor thermostat detects overheating (PTC>12.4k Ω or NTC<0.5k Ω) and needs to cool down before resetting;

Overspeed (J/J1): If the speed exceeds VOSPD (or 1.8 × VLIM), check the speed setting or tuning parameters.

No message fault (only displayed in the status bar):

Limit switch (L1/L2/L3): Hardware limit trigger (CW/CCW switch open circuit), check the limit wiring;

Watchdog (≡): Software malfunction, need to contact the manufacturer;

RAM/EPROM malfunction (I/c): Memory test failed, hardware replacement is required.

(2) Firmware upgrade

Preparation files: The upgrade includes firmware (Lccd_ xxx. emb), Windows tools (Cdlignit. exe), and DOS tools (Ignite. exe).

Steps:

Turn off the power and set DIP switch 8/10 to 1;

Power on and confirm that the status bar displays "E" (entering Ember mode);

Run Cdlignit.exe, select the serial port and baud rate (default 115200), load the firmware file and start downloading;

After successful download, power off and restore DIP switch. After powering on, verify the version through the "VER" command.

Extended Configuration and Appendix

(1) Personality Module

Function: Quickly copy drive parameters, configure one and upload it to the module, then download it to other drives, including All parameters of the SSV file and the CONFIG/SAVE command.

Operation:

Upload: Insert the module into port C1, press and hold the hide switch for 2 seconds, and the status bar will flash with three bars: bottom, middle, and top;

Download: Press the explicit switch, and the status bar will flash up, middle, and down bars;

Fault: Upload error shows "-6", download error shows "-7", module or wiring needs to be checked.

(2) Appendix Key Information

Wiring diagram: Appendix A provides the pin correspondence of motor power supply (such as GOLDLINE B/M/EB/XT series), rotary transformer (LR), and encoder (LE), including line color labeling (such as motor MA corresponding to GOLDLINE B series PinA, brown wire).

Linear motor configuration: Appendix C provides the formula for converting linear parameters to rotational parameters (such as MSPEED=Vmaxl × 60/pole pitch, unit RPM), and the driver parameters need to be calculated based on the motor pole pitch, maximum linear velocity, etc.

Motor Thermostat: Appendix D supports PTC (THERMOTYPE=0) and NTC (THERMOTYPE=1), monitored through pin 13/25 of the C2 interface, triggering an "H" fault when overheated.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands