SERVOSTAR ® CD series servo amplifier

EMI filtering:

Input filtering: EMI filters (such as Cx03 with Corcom F7202A and Cx10 with Schaffner FN258-16/07) need to be installed at the power input end. The filters should be installed tightly against the input end (distance ≤ 30cm, and over distance should be connected with flat braided wire), and the shell should be in contact with the backplate metal (remove oil paint).

Motor filtering: Not mandatory, but it is recommended to add filtering for long motor wires (>25m) or non-metallic cabinets to reduce differential mode noise coupling.

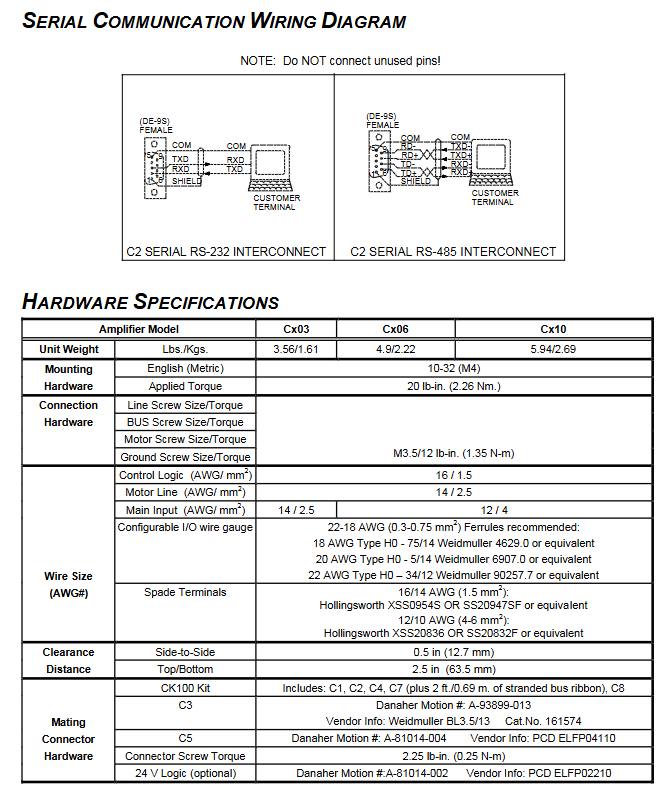

Hardware specifications and electrical parameters

(1) Core electrical parameters

Parameter Cx03 Cx06 Cx10

Continuous output current (RMS) 3A 6A 10A

Peak output current (500ms/RMS) 9A 18A 20A

Input voltage 110-230VAC (± 10%), single-phase/three-phase (Cx0x200 only single-phase) 230VAC (± 10%), three-phase 230VAC (± 10%), three-phase

Bus voltage 325VDC (nominal), overvoltage protection 430VDC, undervoltage protection 90VAC

PWM frequency 16kHz (current loop update rate 62.5 μ s) 8kHz (current loop update rate 62.5 μ s) 8kHz (current loop update rate 62.5 μ s)

Environmental temperature operation: 5-45 ℃ (41-113 ° F), storage: 0-70 ℃ (32-158 ° F)

Cooling power consumption 60W, 80W, 132W

(2) Interface definition

Communication interface C1: Supports RS232 (Pin2=RXD, Pin3=TXD) and RS485 (Pin6=TXD+, Pin7=TXD -, Pin8=RXD+, Pin9=RXD -), used for PC debugging or multi machine networking (MultiDrop address is set by DIP switches 1-5, optional 0-31).

Feedback interface C2 (25 pins):

Resolve: Pin1-2 (sine signal), Pin4-5 (cosine signal), Pin15-16 (reference signal);

Encoder:Pin1-2(A/A)、Pin4-5(B/B)、Pin15-16(Index/Index)、Pin22-24( Hall signals H1A/H2A/H3A); Sine Encoder:Pin1-2(A/A)、Pin4-5(B/B)、Pin9-10(Data/Clock), Requires 5V power supply (Pin18-20).

Expansion interfaces: C4 (equivalent output of encoder, RS485 differential), C8 (remote encoder input), C9 (only Series 5, 3-channel input/2-channel output), C7 (RS232 multi machine communication, CK100 kit required).

DIP switch (10 bits): Switch 1-5 sets MultiDrop address, switch 6 sets baud rate (0=9600/2M, 1=19200/4M), switch 7 sets position hold (1=active), switch 8 sets driver enable (1=disabled), switch 9 sets SERCOS transmit power (1=high power).

Control performance and functionality

(1) Control loop characteristics

Key parameters of control loop update rate and bandwidth

Current loop 62.5 μ s (16kHz)<2000Hz fully digital pole configuration, supports adaptive gain, monitors A/C phase current (IA/IC), with I ² t turn back protection (to prevent driver overheating)

Reversing ring 62.5 μ s (16kHz) - sine wave commutation, supports "torque angle lead" technology, maximum commutation frequency 400Hz, needs to be aligned with the back electromotive force of the motor

Speed loop 250 μ s (4kHz)<400Hz PDFF (pseudo differential feedforward) algorithm, speed resolution 1RPM or VLIM/16384, long-term speed stability 0.01%

Position ring 500 μ s (2kHz) - supports hardware limit (C3 interface IN1/IN2), software limit (PMAX/PMIN), position deviation monitoring (PE>PEMAX triggering fault)

(2) Core functions

Feedback support: Compatible with incremental encoders (A/B/Z+Hall), rotary transformers (single/multi speed), sine encoders (EnDat/HIPERFACE), supports encoder equivalent output (C4 interface, up to 3MHz frequency, scalable resolution).

Protection mechanism: Over temperature (trip at 80 ℃), overvoltage (430VDC), undervoltage (90VDC), overcurrent (power level surge), feedback disconnection (A/B phase/rotary transformer disconnection), motor overheating (thermal monitoring, PTC>12.4k Ω or NTC<0.5k Ω triggering fault).

Regeneration control: Built in braking circuit, activated when the bus voltage reaches 390VDC, external regeneration resistor (ERH-26) can handle excess energy, Cx03 has a minimum resistance of 20 Ω and a maximum power of 200W.

Debugging and troubleshooting

(1) Debugging process

Software installation: Install MOTIONLINK from the CD-ROM or official website (www.danahermotion. com), which supports Windows 95/98/NT 4.0/2000 systems and requires configuration of a serial port (COM1-COM4, baud rate matching DIP switch).

Quick Startup Wizard:

Motor configuration: Select the motor model (such as GOLDLINE series) from the database, click "To Drive" to download parameters. For unknown motors, manually enter parameters such as MBEMF (back electromotive force) and MENCRES (feedback resolution).

Feedback configuration: Select the feedback type (encoder/rotary transformer), confirm the C2 interface wiring, and the rotary transformer needs to perform a zeroing program.

Enable and Test: Connect the 24V enable power supply (C3 Pin7-8), and the software executes the "EN" command to enable the driver. Test the motor rotation through the "Jog" mode and monitor the speed/current (MOTIONLINK monitoring interface).

Firmware upgrade: Series 5 models do not support it. For older models, DIP switch 8/10 needs to be set to 1, enter Ember mode, load the firmware (Lccd_ xxx. emb) using IGNITE tool, and restore the switch to 0 after upgrading.

(2) Troubleshooting

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands