Honeywell Searchpoint Optima Plus Infrared Point Gas Detector

Terminal/Installation Accessories: Provide a full range of hazardous area certified Ex e and Ex d junction boxes, as well as SHC-1 protective devices, to provide electrical protection for SHC-1 when using conventional terminal enclosures.

HART ® communication protocol

Protocol advantage: HART ® Highway Addressable Remote Transformer is a widely used digital communication protocol that allows users to obtain real-time data, status indicators, and diagnostic information from smart field devices by superimposing digital signals on existing analog signals, without the need for additional field wiring, helping to reduce costs. If dedicated handheld devices are not required, engineers can use a single HART ® Handheld devices access all HART devices on site ® Enable the device and query HART at any position in the current loop ® Signal, diagnostic information can be obtained without the need to go to the site, reducing maintenance costs.

The detector supports functions such as viewing gas readings, configuration, and diagnostic information, conducting collision testing, mA loop calibration, gas calibration, simulating alarms, faults, or warnings, setting device tags, IDs, and descriptions, viewing activity warning/fault and event history, forcing mA output to a specific level for testing, configuring real-time clock, configuring suppression, warning, and over range levels, configuring alarm thresholds, changing target gases, and password protected access.

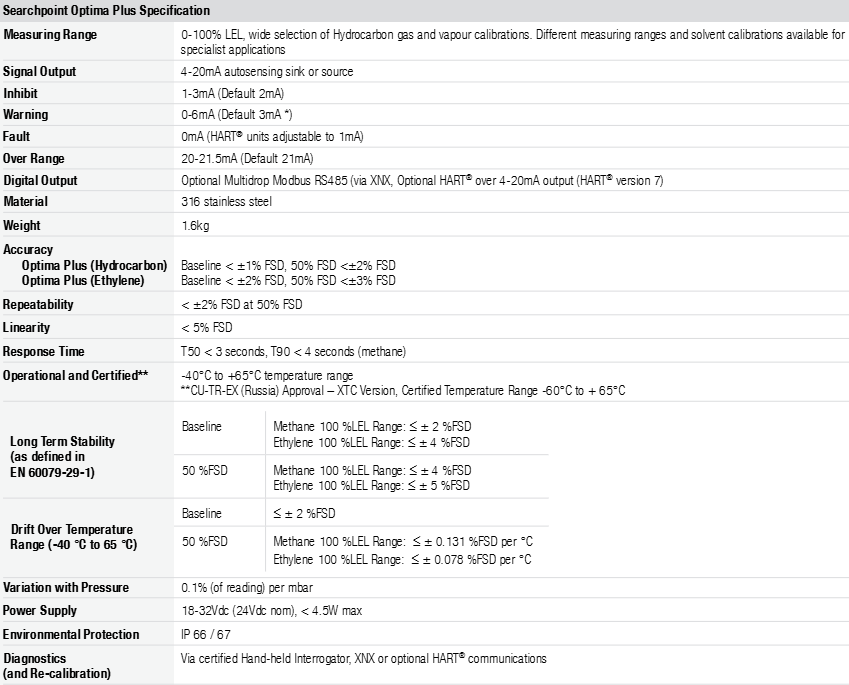

Technical specifications

Project/Details

Measurement range: 0-100% LEL, calibrated for various hydrocarbon gases and vapors, providing different measurement ranges and solvent calibrations for special applications

Signal output: 4-20mA automatic sensing sink or source, suppression: 1-3mA (default 2mA), warning: 0-6mA (default 3mA *), fault: 0mA (HART) ® Unit adjustable to 1mA, over range: 20-21.5mA (default 21mA)

Digital output: optional multi-point Modbus RS485 via XNX, optional HART ® Through 4-20mA output (HART) ® Version 7)

Material: 316 stainless steel

Weight: 1.6kg

Precision Optima Plus (hydrocarbons): baseline<± 1% FSD, 50% FSD<± 2% FSD; Optima Plus (ethylene): baseline<± 2% FSD, 50% FSD<± 3% FSD

Linearity:<5% FSD

Response time: T50<3 seconds, T90<4 seconds (methane)

Operating and certification temperature range: -40 ° C to+65 ° C * *; CU-TR-EX (Russia) certification - XTC version, certified temperature range -60 ° C to+65 ° C

Long term stability (as defined in EN 60079-29-1): baseline methane 100% LEL range: ≤± 2% FSD; Ethylene 100% LEL range: ≤± 4% FSD; 50% FSD methane 100% LEL range: ≤± 4% FSD; Ethylene 100% LEL range: ≤± 5% FSD

Drift within temperature range (-40 ° C to 65 ° C): baseline ≤ ± 2% FSD; 50% FSD methane 100% LEL range: ≤± 0.131% FSD/° C; ethylene 100% LEL range: ≤± 0.078% FSD/° C

Pressure change impact: 0.1% (reading)/mbar

Power supply 18-32Vdc: (nominal 24Vdc), maximum<4.5W

Environmental Protection: IP 66/67

Diagnosis (and recalibration): Certified handheld interrogator, XNX, or optional HART ® communication

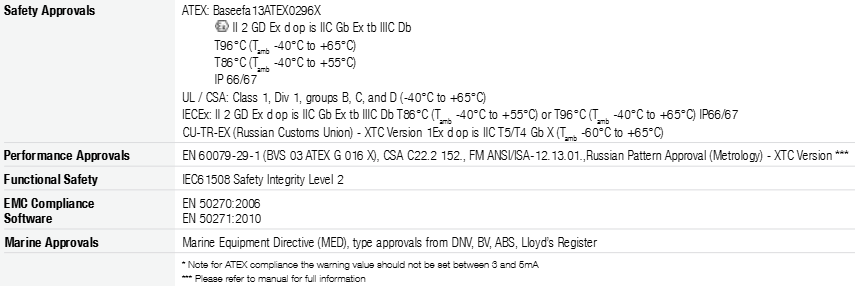

Safety certification: ATEX, UL/CSA, IECEx, CU-TR-EX (Russian Customs Union) and other certifications

Performance certification: EN 60079-29-1, CSA C22.2 152., FM ANSI/ISA-12.13.01., Russian mode approval (metrology) - XTC version, etc***

Functional Safety: IEC61508 Safety Integrity Level 2

EMC compliance: EN 50270:2006, EN 50271:2010

Ship certification: Marine Equipment Directive (MED), DNV, BV, ABS, Lloyd's Register and other type approvals

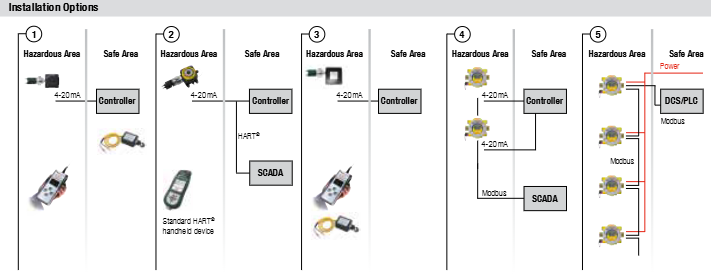

Installation Options

Installation options: Provides multiple installation configurations to adapt to different connection requirements in hazardous and safe areas, such as connecting to controllers, DCS/PLC, SCADA systems, etc., supporting HART ®、 Modbus and other communication methods.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands