How to use Honeywell OELD intelligent junction box

Provide local visual status indication and Bluetooth low-energy interface, which can be configured and maintained through Bluetooth enabled mobile devices, certified by ATEX and IECEx, suitable for Zone 1 (gas) or Zone 21 (dust) hazardous areas, and the explosion-proof version also has cULus certification, suitable for Class I Zone 1 or Class II Zone 1.

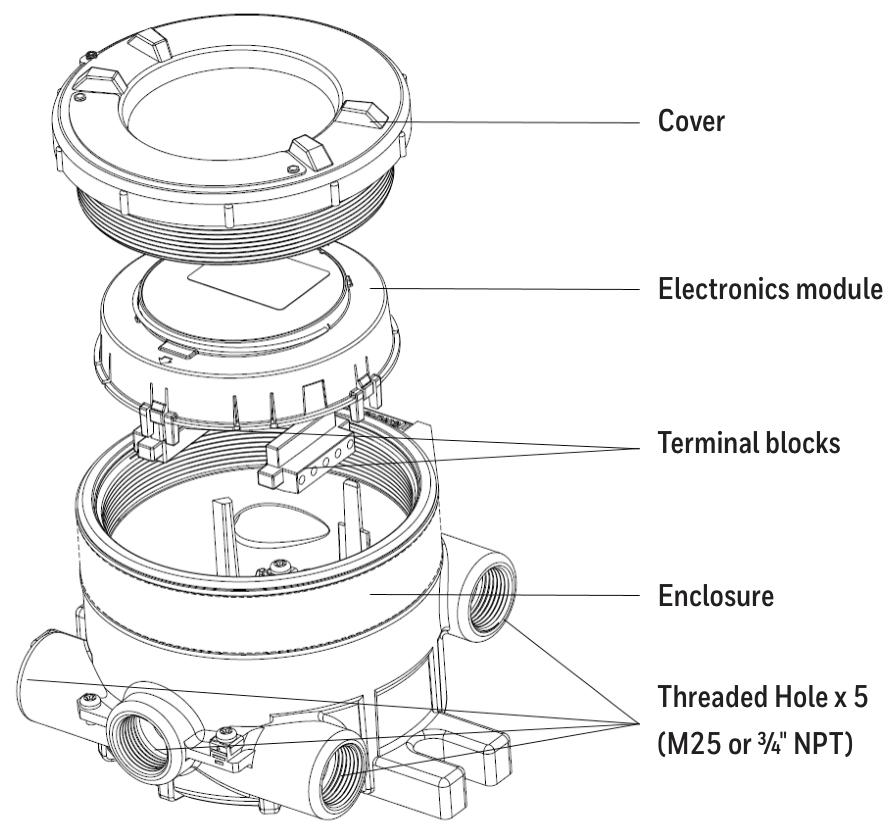

There are 5 entrances (M25 or 3/4 "NPT depending on the version) and 3 certified plugs, while the Ex e version of the OELD only has 5 M25x1.5 entrances.

How to use Honeywell OELD intelligent junction box

Security Warning and Information

The installation must comply with the standards recognized by relevant national authoritative institutions, and reference should be made to EN 60079-14 and EN 60079-29-2 in the European region.

It is strictly prohibited to open the casing when powered on or when there may be explosive atmospheres present.

Operators need to be aware of the measures to be taken when the gas concentration exceeds the alarm level, and must not modify the product structure, otherwise it may render critical safety and certification requirements ineffective.

Only trained personnel are allowed to carry out internal operations of the product. Its measurement function has not obtained ATEX certification, and it is not allowed to rely on the backlight status indication of the OELD display screen for safety related operations. The equipment must not operate in an environment with an oxygen content exceeding 21%.

Special safety conditions for use (increased safety Ex e version)

Each terminal can be connected to a maximum of one single or multiple wires on either side, unless multiple wires are connected in an appropriate manner.

The insulation layer of the wire connected to the terminal should be suitable for the corresponding voltage and extend within 1mm of the terminal throat.

All used and unused terminal screws should be tightened to between 0.5Nm and 0.6Nm, and terminals can only be installed and wired using cables recommended by IECEx KEM 10.0093U.

Disposal and Environmental Protection

The product should be disposed of in accordance with local regulations, including materials such as the shell (aluminum alloy or 316 stainless steel), lid (aluminum alloy or 316 stainless steel, glass).

The product must be disposed of through appropriate WEEE disposal facilities and cannot be treated as general industrial or household waste.

Product Overview

Basic Introduction

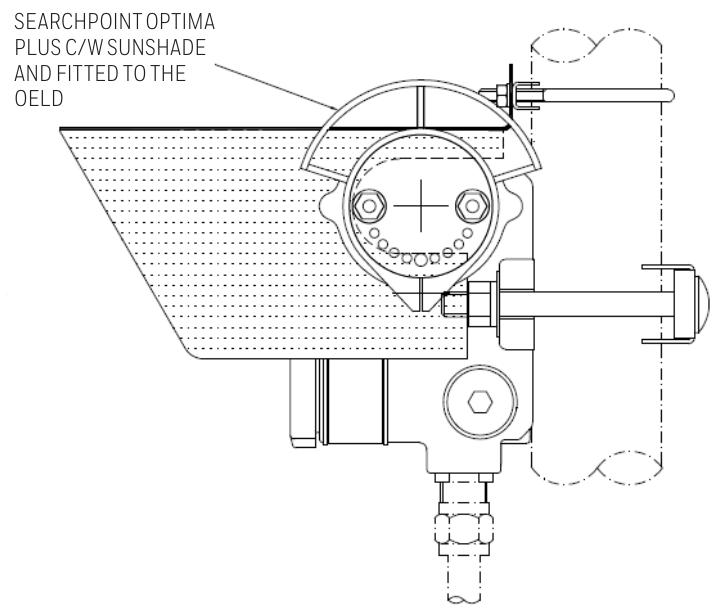

OELD is a certified junction box for hazardous locations, suitable for detectors with 4-20mA output, and can be used in conjunction with Searchpoint Optima Plus or Searchline Excel series gas detectors.

Provide local visual status indication and Bluetooth low-energy interface, which can be configured and maintained through Bluetooth enabled mobile devices, certified by ATEX and IECEx, suitable for Zone 1 (gas) or Zone 21 (dust) hazardous areas, and the explosion-proof version also has cULus certification, suitable for Class I Zone 1 or Class II Zone 1.

There are 5 entrances (M25 or 3/4 "NPT depending on the version) and 3 certified plugs, while the Ex e version of the OELD only has 5 M25x1.5 entrances.

Structure and function

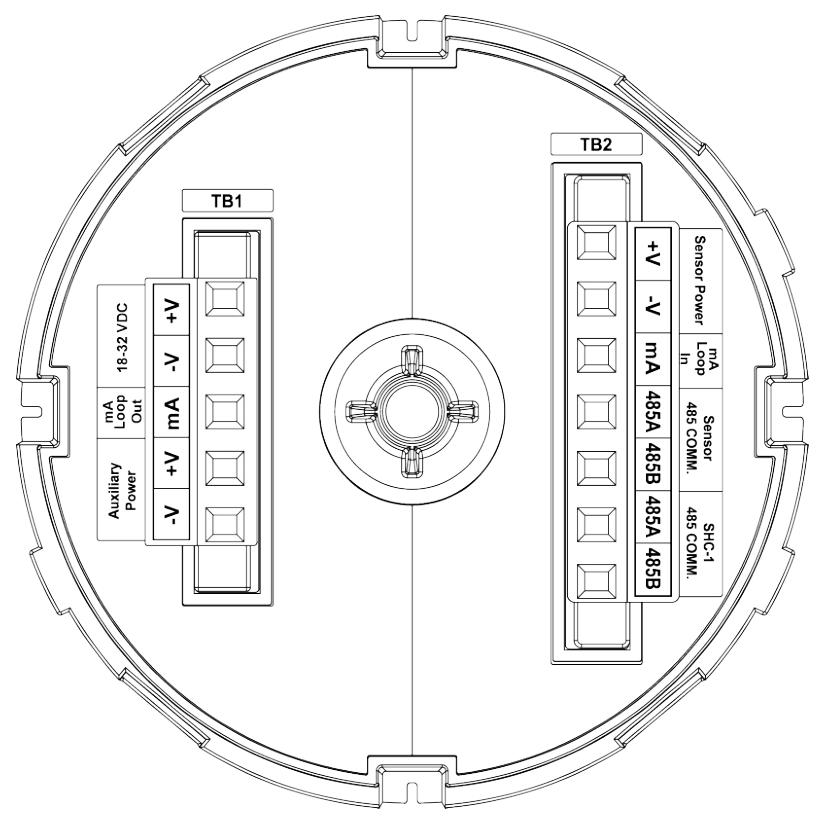

There are two grounding connection points and an electronic module with two pluggable terminal blocks inside the shell, used to connect the field and detector wiring.

Featuring four-color backlighting (green, yellow, red, blue) and a customized 7-segment liquid crystal display (LCD), different backlight colors represent different states, such as green for normal operation or warning, red for alarm, etc.

Options

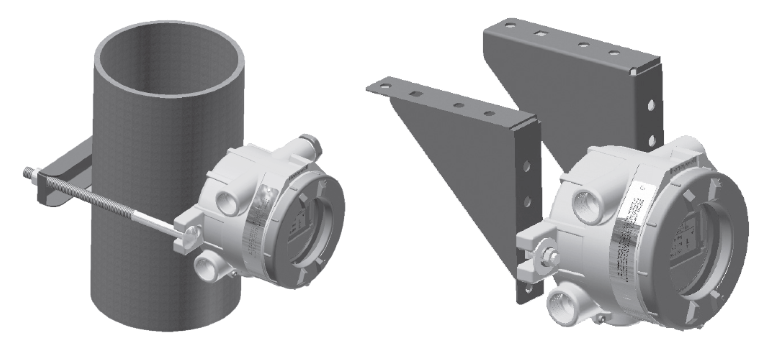

Including pipeline installation kit (1226A0358), which can install OELD on pipelines with diameters ranging from 2 "to 6" (50 to 150mm); Ceiling installation bracket kit (1226A0355), used for ceiling installation; Sun visor (94000-A-1006), made of 316 stainless steel, can protect OELD and related detectors from direct sunlight.

Installation related

Site selection and positioning

The placement of gas detectors should follow the recommendations of gas diffusion experts, process equipment experts, safety personnel, and engineering personnel, and record the protocol for determining the detector location.

Installation designers should refer to IEC/EN 60079-29-2 and other national practice standards, as well as the site selection recommendations for specific locations in the gas detector technical manual.

Mechanical Installation

OELD can be installed in various ways through integrated mounting pads, such as on flat walls Unistrut ® On the bracket, use the optional pipe installation kit to install on the pipeline or utility pole, or use the ceiling installation bracket kit to install on the ceiling.

When installing, it is necessary to consider the correct direction of the detector, ensure that the installation bolts are fully tightened, and use appropriate locking washers.

electrical installation

The detector can be installed directly or remotely to the OELD, and some detectors have corresponding junction boxes for remote installation.

The installation steps include removing the cover, taking out the electronic module, installing cable glands or conduit fittings, installing detectors (with different installation methods for different entrance versions), sealing unused cable entrances, making electrical connections, reinstalling the display module and cover, etc.

Electrical connection

Terminal block definition

Terminal block 1 (TB1) and terminal block 2 (TB2) have different markings, colors, and functions for each terminal. For example, terminal 1 of TB1 is - V (black) and is used for auxiliary power supply.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands