Honeywell Searchpoint Optima Plus Infrared Point Gas Detector

Honeywell Searchpoint Optima Plus Infrared Point Gas Detector

Product Overview

Searchpoint Optima Plus is an advanced infrared point type hydrocarbon gas detector suitable for potentially explosive environments. With its infrared detection principle, it has the characteristics of fast response, fault safe operation, etc., which can ensure factory compliance, personnel safety, and maximum uptime of the production process. Compared with traditional electrocatalytic gas detectors, it can reduce daily maintenance and overall cost of ownership.

Global application foundation: Based on over 40 years of design, manufacturing, installation, and maintenance experience, more than 100000 infrared point type hydrocarbon gas detectors have been installed worldwide, with a wide range of application scenarios, from light industry to demanding offshore petrochemical environments.

Typical applications: including environments where catalytic bead toxins or inhibitors may exist, as well as harsh environments that require extended daily maintenance intervals, such as offshore oil and gas platforms, floating production storage and offloading (FPSO) vessels, oil tankers, onshore oil and gas terminals, refineries, LNG/LPG bottling plants, etc.

Detectable gases: Over 100 types of gases and vapors can be detected. For specific lists, please consult the customer support team or local distributors.

Core advantages

Advantages of infrared technology: It has the characteristics of fault safe operation, fast response speed, reduced daily maintenance, not affected by catalytic toxins, long service life, and can work in inert environments.

Product Features:

Accumulated experience in installing over 100000 units worldwide, with higher reliability.

Optional HART ® The protocol outputs through 4-20mA.

Can detect various hydrocarbon gases, including solvents.

No moving parts, higher reliability; The self compensating optical system enhances stability and is not affected by long-term component drift.

Capable of remote functional gas testing and certified for hazardous areas in North America and Europe.

Enhance false alarm elimination capability, with pollution optical warning to improve uptime, dynamic heating control to ensure no condensation or undetected faults in the optical system.

Improved diagnostic functions, integrated event logs, reduced power consumption, and certified through various hazardous area classification schemes such as ATEX, UL, CSA, IECEx, etc.

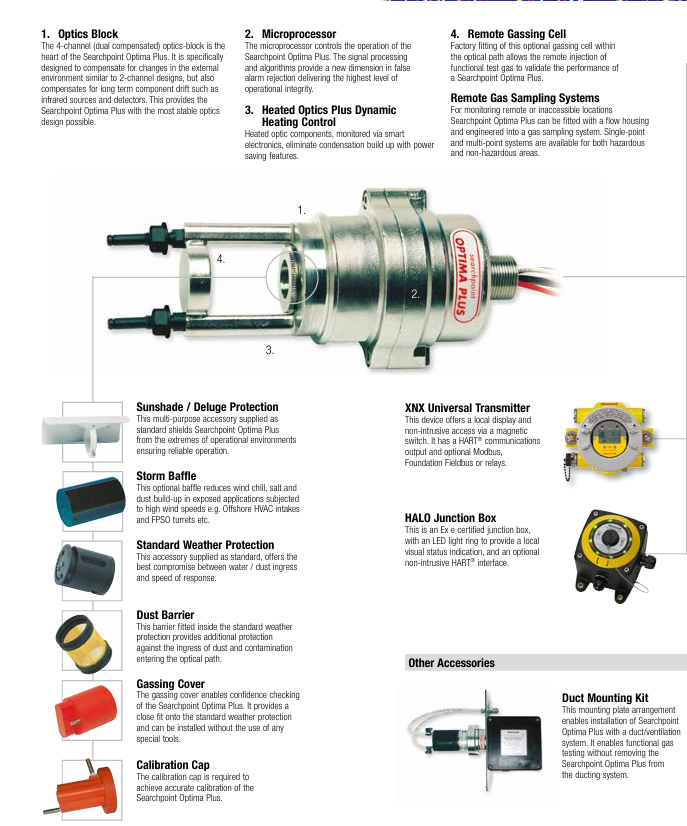

Core Technologies and Components

Optical module: The 4-channel (dual compensation) optical module is the core, which not only compensates for external environmental changes like the 2-channel design, but also compensates for long-term component drift such as infrared light sources and detectors, providing the most stable optical design.

Microprocessor: controls the operation of the detector, and its signal processing and algorithms reach new heights in false alarm elimination, providing the highest level of operational integrity.

Heating optical system and dynamic heating control: The heated optical components are monitored by intelligent electronic devices, which have energy-saving functions and can eliminate condensation accumulation.

Remote gas injection unit: The optional remote gas injection unit is installed in the optical path at the factory and can remotely inject functional test gases to verify detector performance.

Sampling system and accessories

Remote gas sampling system: For remote or difficult to access locations, flow enclosures can be equipped and integrated into the gas sampling system, providing single point and multi-point systems suitable for hazardous and non hazardous areas.

Main accessories:

Sunshade/Rain Protection: Standard multifunctional accessories to protect the detector from extreme environmental impacts and ensure reliable operation.

Storm Barrier: Optional barrier to reduce wind chill, salt, and dust accumulation in high wind exposure applications.

Standard weather protection: Standard equipment, achieving the best balance between waterproof/dustproof and response speed.

Dust barrier: Installed inside the standard weather protection, it additionally prevents dust and pollutants from entering the light path.

Gas injection cover: can confirm the performance of the detector, closely matched with standard weather protection, and can be installed without special tools.

Calibration cap: used to achieve accurate calibration of detectors.

XNX Universal Transmitter: Provides local display and non-invasive access through magnetic switches, with HART capability ® Communication output and optional Modbus, Foundation fieldbus, or relays.

HALO junction box: Ex e certified junction box with LED halo for local visual status indication, optional non-invasive HART ® Interface.

Pipeline installation kit: Installation plate device, which can install the detector in the pipeline/ventilation system without removing it from the pipeline system for functional gas testing.

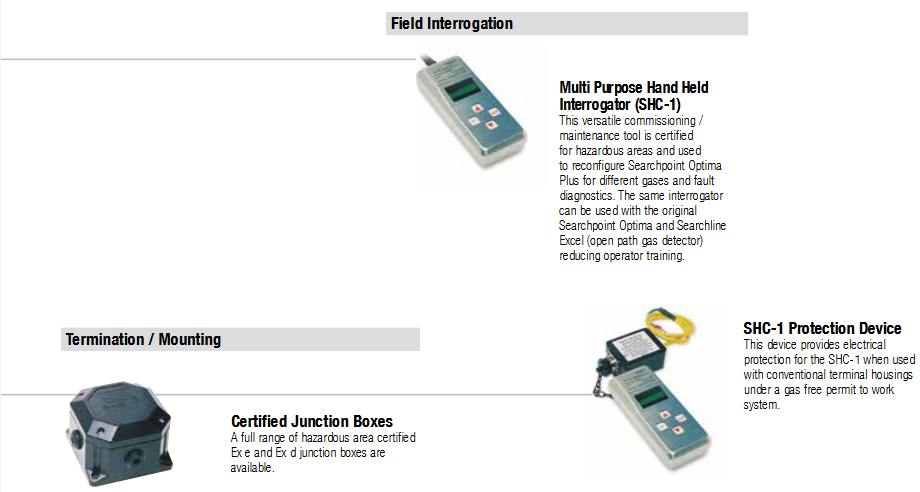

On site inquiry tool: The multifunctional handheld interrogator (SHC-1) is a certified debugging/maintenance tool for hazardous areas, which can reconfigure detectors to adapt to different gases and perform fault diagnosis. It can also be used for raw Searchpoint Optima and Searchline Excel (open circuit gas detectors), reducing operator training.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands