Honeywell Sensepoint XCD gas detector

Honeywell Sensepoint XCD gas detector

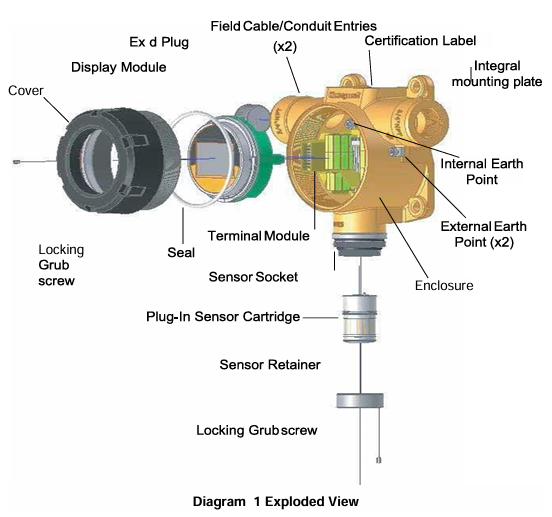

Product overview

Sensepoint XCD is a fixed gas detector suitable for hazardous areas such as Zone 1/2 and Class I Division 1/2. It can detect flammable gases, toxic gases, and oxygen, and achieve safety monitoring through 4-20mA signal output and programmable relays. It supports Modbus communication (optional), non-invasive operation (magnetic rod activation), and explosion-proof certification. It is widely used in industrial scenarios such as petroleum and chemical industries.

Core functions and technical features

1. Detection capability

Applicable gases:

Flammable gases: methane, propane, etc. (catalytic combustion or infrared technology).

Toxic gases: hydrogen sulfide (H ₂ S), carbon monoxide (CO), hydrogen (H ₂), nitrogen dioxide (NO ₂), etc. (electrochemical technology).

Oxygen (O ₂): Detection concentration range 0-25% Vol (electrochemical technology).

Performance parameters:

Response time (T90): Flammable gas<25 seconds, toxic gas<65 seconds, oxygen<30 seconds.

Accuracy: ± 1.5% LEL (flammable gas), ± 20% or specific value (toxic gas).

2. Output and Communication

Analog output: 4-20mA current signal (configurable as source or drain mode), output<1mA in case of fault, output 2mA or 4mA in suppression mode (17.4mA in oxygen version).

Relays: 3 programmable relays (default A1, A2, fault), supporting normally open/normally closed switching, contact capacity 5A@250VAC .

Optional Modbus RTU: communicates via RS485, supports 9600/19200 baud rates, and can transmit data such as gas concentration and alarm status.

3. Operation and Configuration

User interface: LCD display screen, displaying gas concentration, alarm status, fault codes, etc., operated through magnetic stick activation buttons.

Menu function: Supports calibration, parameter configuration (range, alarm threshold, relay action, etc.), password protection (default 0000).

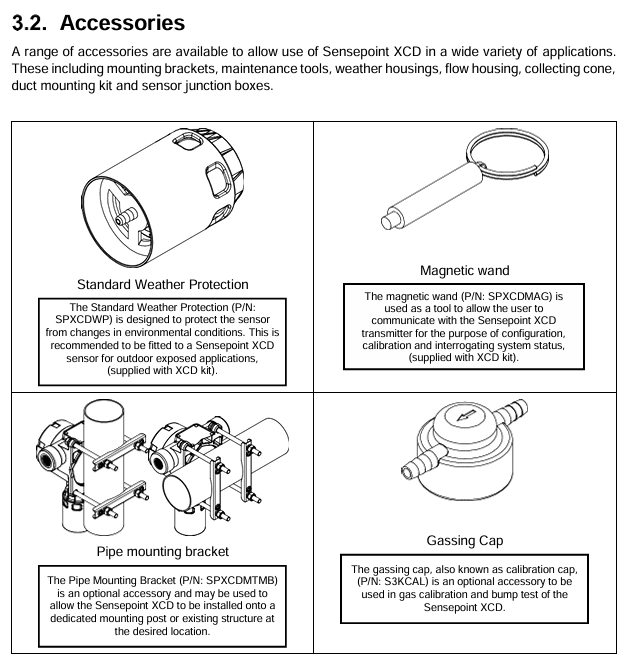

Calibration: A calibration cap (S3KCAL) is required, which supports zero and range calibration. It is recommended to perform it every 6 months.

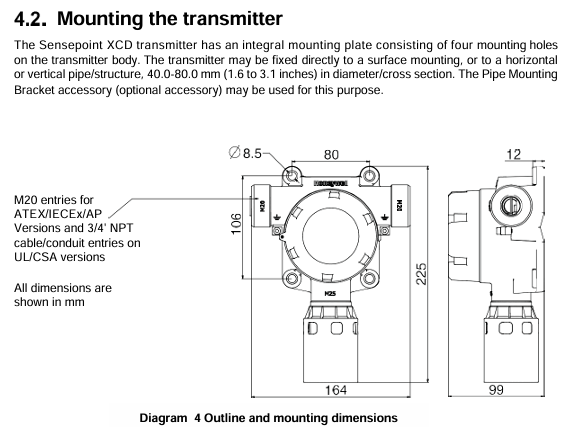

Installation and wiring

1. Installation requirements

Environmental conditions: working temperature -40 ° C to+75 ° C, humidity 10-99% RH (non condensing), protection level IP66.

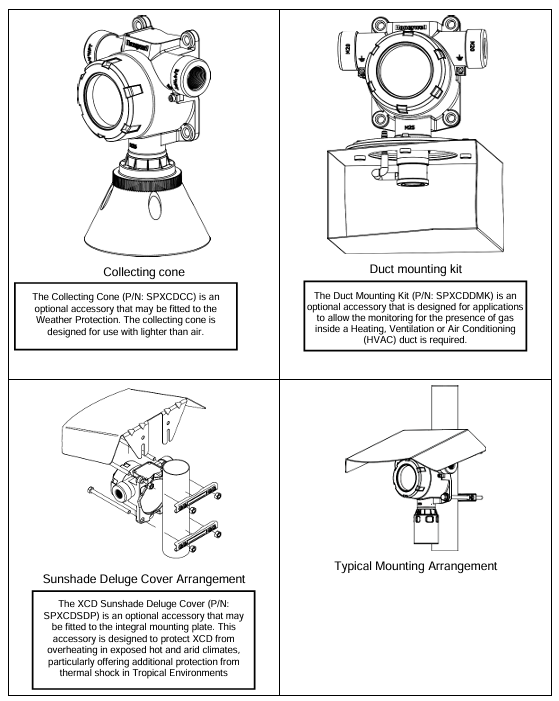

Installation position: Select according to the gas characteristics (such as lighter than air gas requiring a collection cone), and the sensor sintering surface should face downwards to ensure IPX6 protection.

Explosion proof requirements: Cable entrances must be equipped with sealed joints, with a distance of ≤ 18 inches (45cm) from the detector, and grounding must be connected at a single point to avoid loops.

2. Wiring specifications

Power supply: 12-32VDC (UL version) or 16-32VDC (ATEX/IECEx version), power consumption ≤ 5.5W.

Cable selection: It is recommended to use shielded twisted pair cables with a cross-sectional area of 0.5-2.5mm ² (20-13 AWG) and a maximum Modbus transmission distance of 1000 meters.

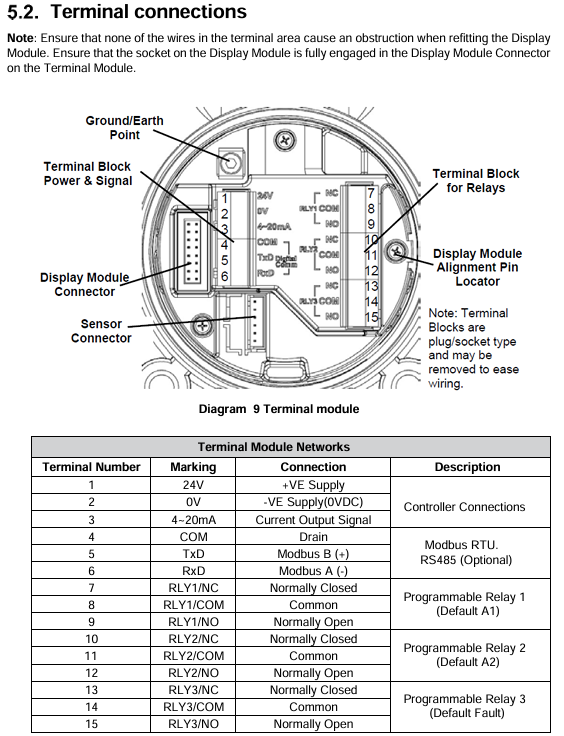

Terminal definition: including power supply, 4-20mA signal, relay, Modbus (optional) interface, specific wiring needs to refer to the terminal table.

Calibration and maintenance

1. Calibration process

Zero point calibration: performed in clean air or using zero gas (such as compressed air).

Range calibration: Introduce 50% of the full range standard gas and confirm the calibration value after stabilization.

Special requirement: The hydrogen sulfide sensor needs to be zeroed with compressed air to avoid the influence of humidity; Infrared sensors need to complete both zero and range calibration simultaneously.

2. Daily maintenance

Sensor replacement: Power off operation is required, and recalibration is needed after replacement. The lifespan of the sensor is usually 2-5 years (depending on the type).

Troubleshooting: By using fault codes (such as F02 indicating sensor failure and F03 indicating zero drift), common problems include wiring errors, power supply failures, sensor aging, etc.

Regular inspection: It is recommended to conduct a bump test every 6 months to ensure that the sensor responds properly

ATEX

ATEX/UKEX:

Certification numbers: UL 21 ATEX 2619X (transmitter), UL 21 ATEX 2620X (sensor head)

Protection level: II 2 GD Ex db IIC T6 Gb (-40 ° C to+65 ° C), Ex tb IIIC T85 ° C Db (-40 ° C to+65 ° C)

Additional requirement: Ensure static grounding to avoid sparks generated by friction.

IECEx:

Certification number: IECEx UL 21.0105X (transmitter), IECEx UL 21.0106X (sensor head)

Protection level: Ex db IIC T6 Gb (-40 ° C to+65 ° C), Ex tb IIIC T85 ° C Db (-40 ° C to+65 ° C).

UL/cUL:

Certification Number: E480011

Applicable area: Class I, Division 1/2(Groups B、C、D)、Class II, Division 1/2(Groups E、F、G)

Temperature range: -40 ° C to+65 ° C.

Performance and Security Certification

European standards:

EN 60079-29-1 (Flammable Gas Performance), EN 45544 (Toxic Gases), EN 50104 (Oxygen).

Other certifications:

Classification society certification (DNV, ABS, CCS, etc.), CE mark (compliant with EN 50270 electromagnetic compatibility standard).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands