How to install the Honeywell Series 3000 MkII and MkIII gas detectors?

Honeywell Series 3000 MkII and MkIII gas detectors

Product Overview

The Honeywell Series 3000 MkII and MkIII are 2-wire loop powered toxic gas and oxygen detectors suitable for potentially explosive environments. They come in explosion-proof and intrinsic safety versions, capable of comprehensively monitoring toxic gas and oxygen hazards. They are suitable for indoor and outdoor installation and have excellent versatility.

MkII: Equipped with a flameproof casing and sensor connections that are inherently safe, it is mainly suitable for Zone 1 locations. When paired with an optional remote installation kit, the sensor can be installed in Zone 0 environments.

MkIII: It needs to be used in conjunction with a separate suitable intrinsic safety barrier and can be used in Zone 0, Zone 1, Zone 2, Zone 20, Zone 21, or Zone 22 locations.

Core advantages

Reliable detection: using mature electrochemical sensing technology and Surecell ™ Electrochemical batteries are suitable for high temperature and high humidity environments, with long sensor life and patented "Reflex" sensor verification and diagnostic functions.

Reduce installation costs: Equipped with integrated surface mount lugs, providing optional horizontal or vertical pipe mounting brackets, explosion-proof transmitters allow for on-site wiring to be laid together with other non intrinsic safety instruments, plug-in sensors do not require wiring and can replace Series 2000 series for refurbished installation.

Reduce debugging costs: The sensor recognition function can automatically configure the transmitter, support non-invasive configuration, and be equipped with plug and play factory configured sensors.

Reduce maintenance costs: Intrinsically safe sensor connections allow for hot swapping, reducing downtime. Users can set calibration frequencies and have integrated fault diagnosis software and menu/icon driven calibration programs.

Regulatory compliance: Complies with regulatory requirements in Europe (ATEX), the United States (UL), Canada (c-UL), South America (Inmetro), International (IECEx), and other regions.

Installation related

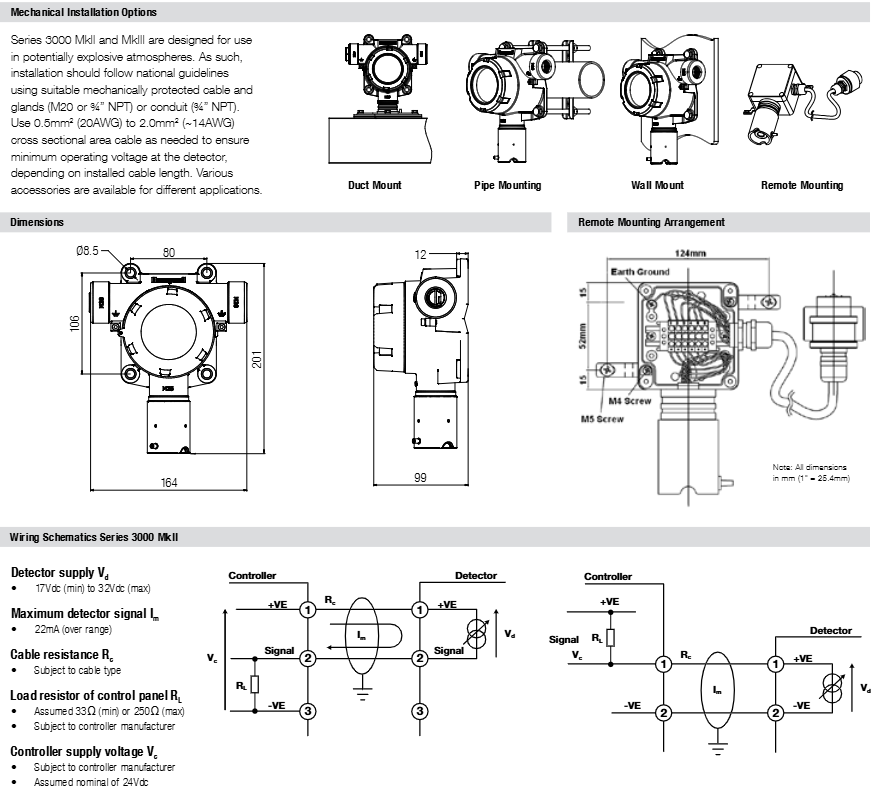

Installation method: Integrated installation ears can be used for wall mounting, or optional pipeline installation kits can be used for pipeline installation (horizontal or vertical). It also supports pipeline installation, remote installation, etc.

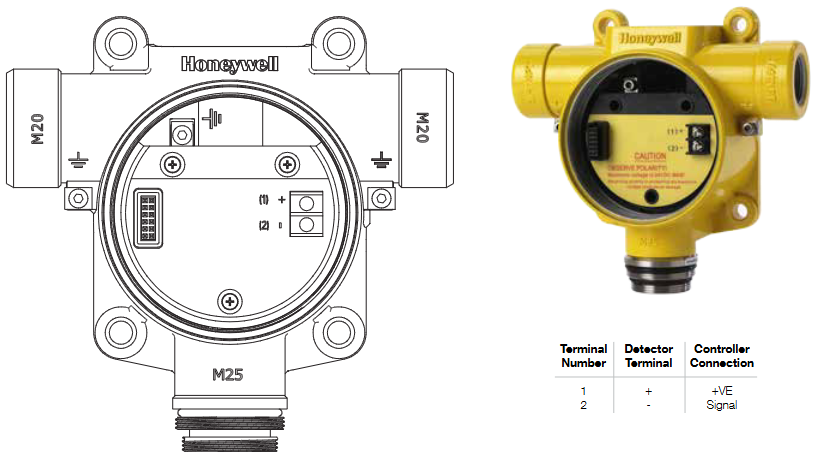

Electrical installation: ATEX/IECEx version uses 2 M20 cable entries, UL/c-UL version uses 2 three-quarters "NPT conduit entries, equipped with suitable plugs to seal unused entries, including weatherproof caps to withstand the harshest outdoor conditions.

Cable requirements: Depending on the length of the installed cable, cables with a cross-sectional area of 0.5mm ² (20AWG) to 2.0mm ² (approximately 14AWG) should be used to ensure the minimum operating voltage of the detector.

Size: The transmitter size is 164mm x 201mm x 99mm (6.4 "x 7.9" x 3.9 "), and other related components have their own specific sizes.

Weight: LM25 aluminum alloy material weighs approximately 1.7kg (3.75lbs), 316 stainless steel material weighs approximately 3.7kg (8.16lbs).

Electrical specifications

Power supply: The MkII is powered from 17Vdc (± 10%) to 32Vdc (maximum), with a maximum current of 22mA (over range); The MkIII is powered from 10Vdc (± 10%) to 30Vdc (maximum), with a maximum current of 22mA (out of range).

Signal output: 0-100% full range 4-20mA, fault status 3mA, calibration expiration can choose to turn off or output 3mA, maximum over range 22mA, toxic sensor suppression can choose 3mA or 4mA, oxygen sensor suppression can choose 3mA or 17.4mA.

Cable length: The maximum cable length of MkII depends on the minimum guaranteed power supply voltage of the controller, the minimum operating voltage of the detector, the maximum current consumption of the detector, the input impedance of the controller, and cable resistance, etc; When calculating the maximum cable length for MkIII, the limiting factors are total capacitance and inductance, which need to consider the fixed capacitance and inductance of barriers and isolators, as well as the capacitance and inductance per meter or kilometer of the cable.

Wiring schematic: MkII and MkIII have their own different wiring schematic, and MkIII also provides some recommended barriers and isolators for use.

Technical parameters

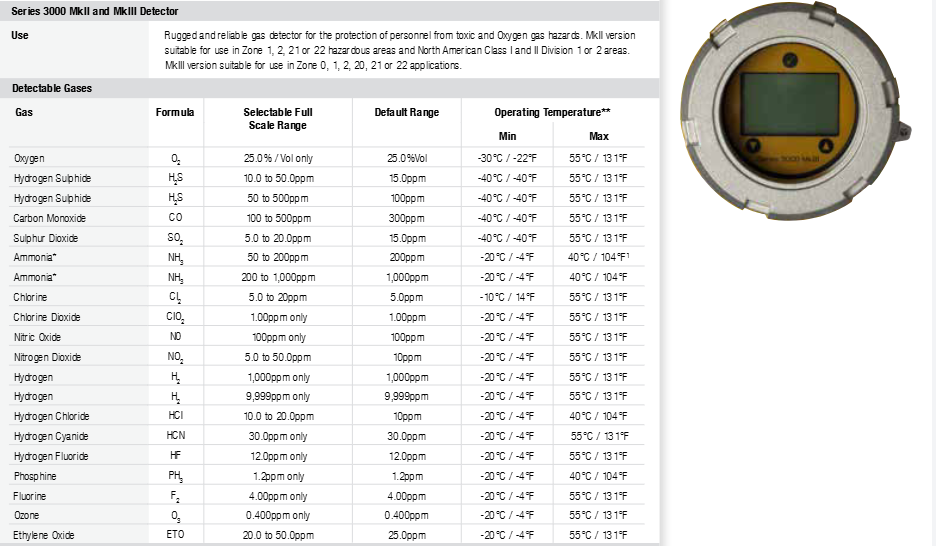

Detectable gases: including oxygen (O ₂), hydrogen sulfide (H ₂ S), carbon monoxide (CO), sulfur dioxide (SO ₂), ammonia (NH ∝), and other gases, each with a corresponding optional full-scale range and default range.

Working temperature: Different certification versions and models vary. The ATEX/IECEX version MkII ranges from -20 ° C to+55 ° C (-4 ° F to+131 ° F), while the MkIII ranges from -40 ° C to+55 ° C (-40 ° F to+131 ° F); The UL/c-UL version is from -40 ° C to+55 ° C (-40 ° F to+131 ° F).

Working humidity: Continuous 20-90% RH (no condensation), intermittent 0-99% RH (no condensation).

Work pressure: 90-110kPa.

Storage conditions: 15 ° C to 30 ° C (59 ° F to 86 ° F), 30-70% RH (non condensing).

Protection level: IP66 (EN 60529), NEMA 4X.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands