Woodward TG-13 and TG-17 speed controllers

Woodward TG-13 and TG-17 speed controllers

Overview

Introduction: This manual (04042C) provides overall instructions, installation, operation, adjustment, operating principles, troubleshooting, and replacement of spare parts for Woodward TG-13 and TG-17 governors.

Describe

TG-13 and TG-17 are mechanical hydraulic differential governors used to control steam turbines that do not require synchronous (constant speed) operation.

The maximum rotation angle of the output shaft of the governor is 40 °, and the recommended angular travel from no-load to full load is 2/3 of the governor's full travel.

The maximum working capacity of TG-13 is 12.2 foot pounds, and TG-17 is 17.5 foot pounds (at 40 ° full stroke of the governor).

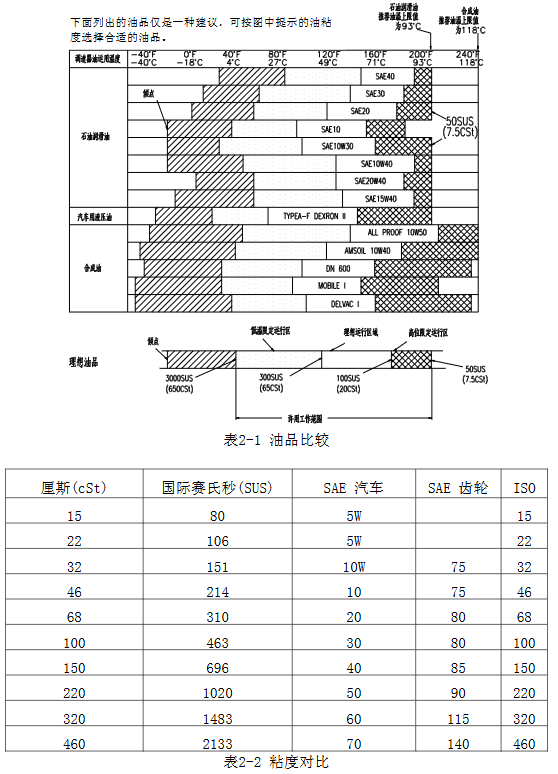

The internal gear pump has different size specifications, suitable for different standard speed ranges such as 1100 to 2400 rpm, 2400 to 4000 rpm, 4000 to 6000 rpm, etc.

During operation, the internal oil pressure of TG-13 is 1034kPa (150psi), while the oil pressure of TG-17 is 1379kPa (200psi).

The governor housing comes in two types: cast iron and cast aluminum. There is a speed difference type, and the internal adjustment setting has a difference rate before leaving the factory. The speed adjustment methods include screw type (standard configuration) and lever type (optional configuration).

The rotation direction of the drive shaft is unidirectional and can be changed on site. The cast iron casing needs to be adjusted internally, while the cast aluminum casing can be adjusted externally (by removing 4 bolts and rotating the pump body 180 °).

Simple maintenance, few coupling parts, fully enclosed design, internal circulation of pressure oil, oil level indicator mounting holes on both ends of the shell, easy to check the oil level.

Install

Introduction: When handling and installing, be careful to avoid hitting the transmission shaft, output shaft, speed setting shaft or speed control screw, to prevent damage to the seal, internal parts and factory settings. Do not use the speed control transmission shaft as a support to place the speed control.

Reception: The speed controller is fixed on a wooden base with bolts when shipped from the factory, vertically placed and packed in a packaging box. There are oil level indicators on both sides of the shell, and the oil filling cover is installed in a vertical installation and operation position. After factory testing and calibration, the rear seat is empty, sealed and painted. There is a small amount of oil film on the surface of the internal parts to prevent rust, and the exposed shaft is sprayed with rust proof oil. There is no need to clean or rinse the interior before installation, operation or retesting.

Storage: It can be stored directly in the short term. In harsh environments or long-term storage, it is necessary to refuel and follow the packaging instructions in Woodward manual 25075 "Packaging for Commercial Storage of Mechanical Hydraulic Controllers". If the oil cap is in a horizontal running position and needs to be placed vertically, the oil cap and screw plug should be removed and replaced before oil injection to prevent leakage.

Drive shaft rotation direction

Looking down from the top of the governor, define the direction of rotation of the drive shaft, and mark the nameplate with "CW" (clockwise) or "CCW" (counterclockwise).

The transmission shaft has only one rotation direction, and the rotation direction viewed from the top should be the same as the rotation direction of the engine transmission shaft viewed from the mounting seat downwards. Otherwise, the oil pump cannot establish oil pressure, resulting in component heating and rotating component jamming.

Change the rotation direction of the transmission shaft

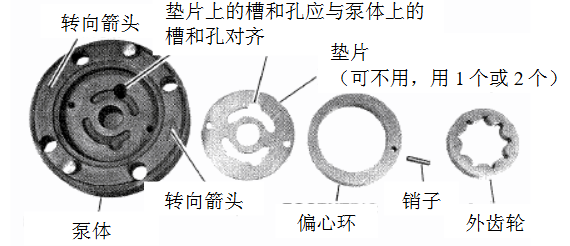

Governor with eccentric gear pump not on the lower body: Remove the governor and drain the oil, place it flat with the cooling joint facing up, rotate the transmission shaft so that the keyway is facing up, loosen the 4 pump body bolts, remove the pump body, rotate the eccentric ring so that the pin hole is close to the desired direction arrow, insert the pin, install the inner and outer gears, install the pump body on the transmission shaft and tighten it, confirm that the transmission shaft rotates flexibly, install the sleeve stop ring and leave the gap.

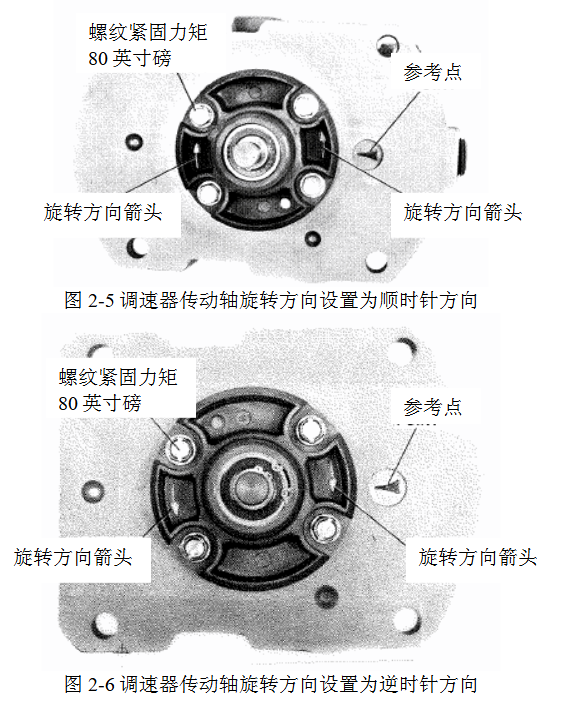

Gear pump eccentric speed regulator on the lower body: Remove the 4 bolts of the pump body, rotate the pump body 180 °, align the pump body arrow with the reference point of the housing. If it is screw speed regulation, screw in the speed screw clockwise. If it is lever speed regulation, turn the speed setting shaft to the maximum fuel position and hold it. Install the bolts and confirm that the transmission shaft rotates flexibly. Remove the upper cover to confirm that the sleeve rotates with the transmission shaft.

Governor installation

It can be installed horizontally or vertically. The oil cap and drain plug are installed in the factory in the vertical running position. If installed horizontally, they need to be moved to the corresponding position to ensure that the power piston is completely immersed in oil, and the oil level indicator also needs to be moved to the correct position.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands