GE VMIVME-2528 128 bit TTL digital I/O TURBOModule ™

Document information: Document number 500-002528-000N, revised on September 30, 1994

Company Information: Produced by VME Microsystems International Corporation, with a company address of 12090 South Memorial Parkway, Huntsville, AL 35803-3308, Contact phone numbers (205) 880-0444, 1-800-322-3616

Trademark information: BITMODULE ™、 MEGAMODULE ™、 TURBOMODULE ™ The VMIC logo is a registered trademark of the company

Configuration and installation

Unpacking procedure: Product components may be sensitive to electrostatic discharge, unused boards should be stored in their original packaging, and it is recommended to use conductive materials when placing them. After receiving them, check for any transportation damage and handle them promptly

Physical installation: Power off installation or removal of the board, insert the board into the appropriate slot of the chassis, ensure correct alignment and orientation

Jumper and switch positions: Refer to Figure 5.3-1 for information on jumper and switch positions

I/O port direction jumper configuration: Table 5.4-1 specifies the use of jumpers J10 to J25, and installing jumpers will configure the corresponding ports as input ports

Address modifier: Factory configured to respond to short monitoring I/O access, installing jumper J9 can be changed to respond to short non privileged I/O access

Address selection switch: There are two address selection switches on the board, and Figure 5.6-1 shows their use in the addressing scheme

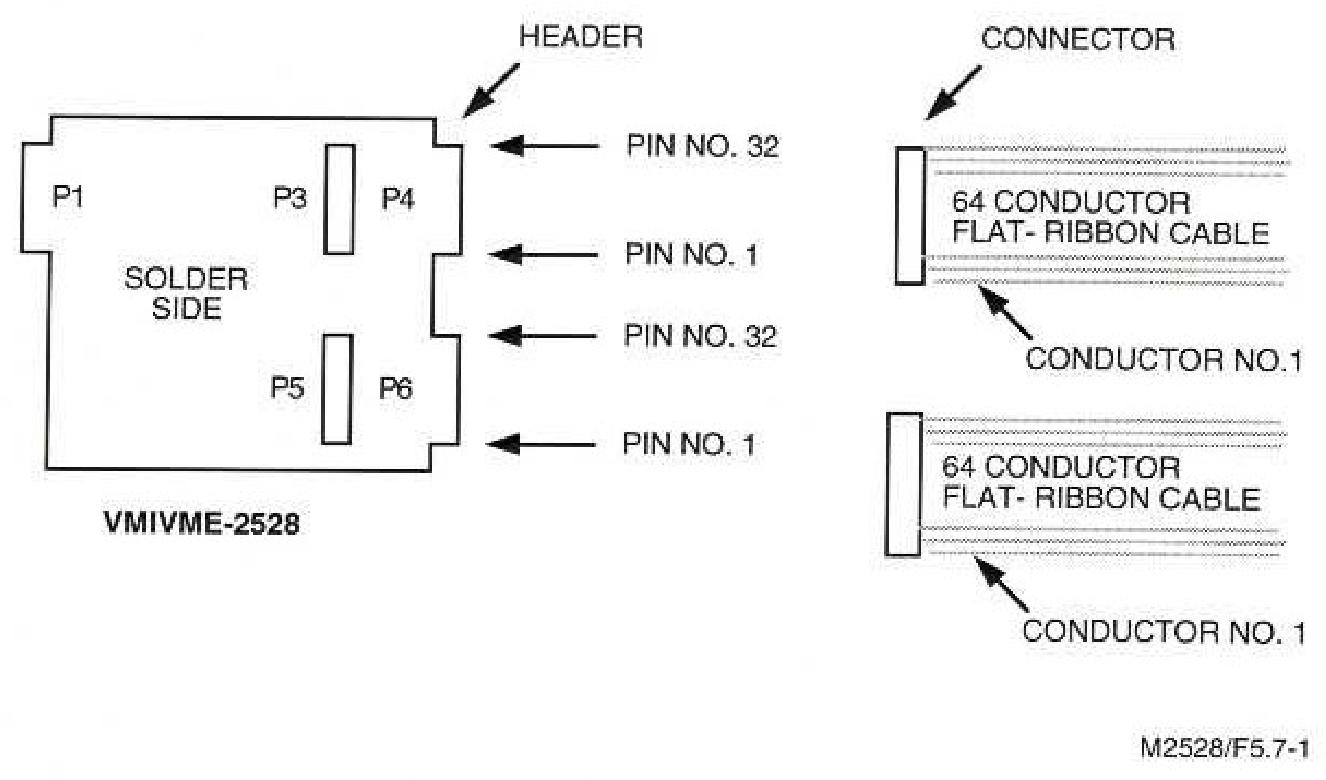

I/O cable and card edge connector configuration: The I/O connectors (P3 to P6) are 64 pin DIN standard, designed with high-quality ground planes connected to VMEbus ground and alternating I/O pins for connectors. They support connection to connectors P3, P4, P5, and P6 through four cables and have connector pin/channel allocation tables

Maintenance

Maintenance points: When the product malfunctions, it is necessary to check the software, system configuration, electrical connections, jumper or configuration options, whether the board is fully inserted, whether the connector pins are clean, whether adjacent board components are interfered with, cable and I/O connection quality, etc. If it needs to be returned for repair, it is necessary to contact VMIC to obtain a Return Merchandise Authorization (RMA) number

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands