Honeywell XNX Universal Transmitter Installation and Configuration Method

Honeywell XNX Universal Transmitter Installation and Configuration Method

Product Overview

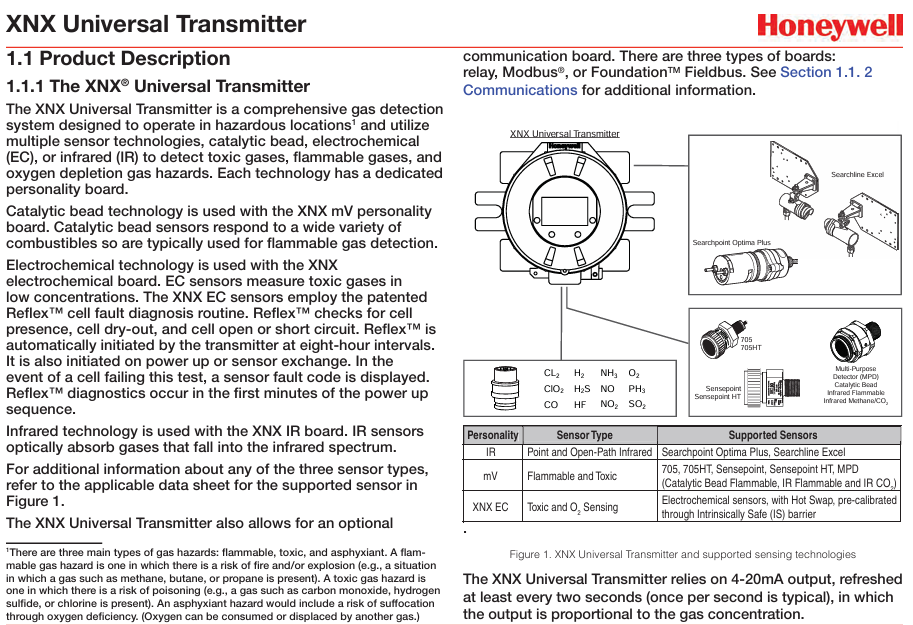

XNX Universal Transmitter is a comprehensive gas detection system launched by Honeywell, suitable for hazardous locations. It can be combined with various sensor technologies such as catalytic beads, electrochemical (EC), or infrared (IR) to detect gas hazards such as toxic gases, flammable gases, and oxygen deficiency. It supports multiple communication protocols and has flexible installation and configuration methods, aiming to provide reliable gas monitoring solutions for industrial scenarios.

Core functions and technical features

Sensor compatibility

Supports catalytic bead sensors (for detecting flammable gases), electrochemical sensors (for detecting low concentration toxic gases), and infrared sensors (for detecting gases within the infrared spectral range).

Compatible with various specific sensors, such as MPD (Multi Purpose Detector), 705 series, Sensepoint series, Searchpoint Optima Plus, Searchline Excel, etc.

Communication function

Standard communication: 4-20mA current loop HART digital communication, configurable as Sink, Source (3-wire system) or Isolated (4-wire system) electrical interfaces.

Optional communication interfaces: Relay (3 Form C contacts for alarm and fault indication), Modbus (supports RTU protocol, communicates through RS-485 physical layer), Foundation Fieldbus (digital communication system, supports multi device connection).

Operation and Configuration

User interface: Equipped with a custom backlit LCD display screen, non-invasive operation through magnetic wands, supporting 8 languages (English, Spanish, German, Italian, Portuguese, French, Russian, Chinese).

Menu functions: including configuration (language, date and time, sensor type, gas selection, etc.), testing (suppression, forced mA output, relay testing, etc.), information viewing (alarm/fault status, transmitter data, etc.), calibration, and other menus.

Security settings: Supports two-level password protection (Level 1 for daily maintenance and Level 2 for technical personnel and password management), requires resetting the factory default password to prevent unauthorized access.

Calibration and maintenance

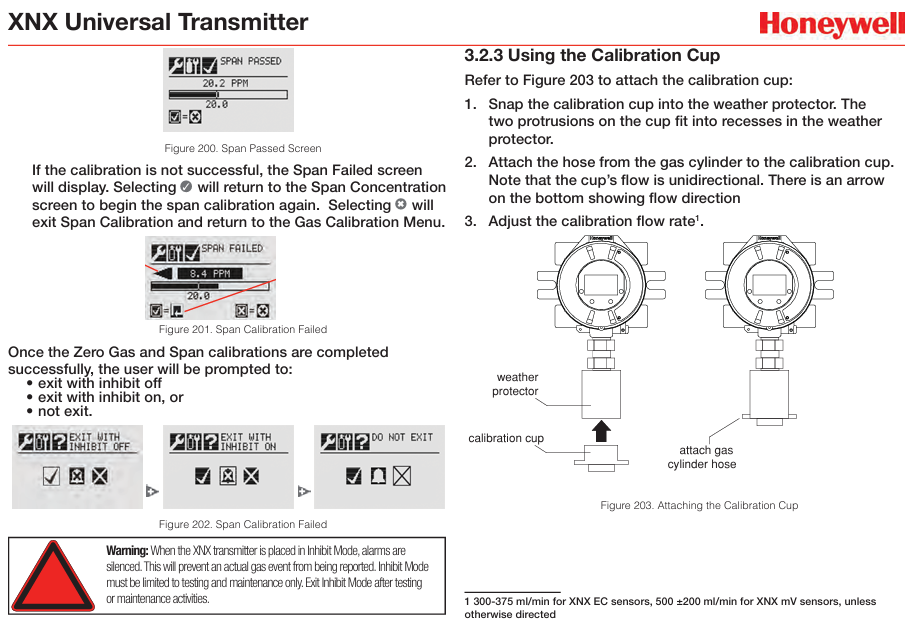

Calibration types: including zero calibration, range calibration, functional gas testing (collision testing), mA output calibration, etc.

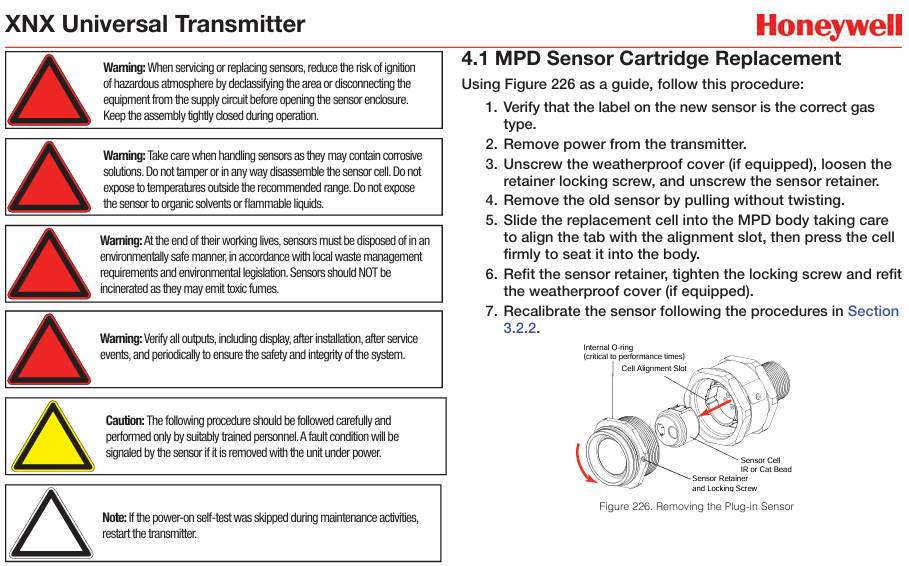

Sensor replacement: Detailed instructions on the replacement steps for MPD sensor cartridge and XNX EC sensor cartridge, which require recalibration after replacement.

Maintenance precautions: When handling sensors, attention should be paid to corrosion prevention, avoiding high temperatures and organic solvents, etc. Sensor scrapping must comply with environmental protection requirements.

Specification parameters

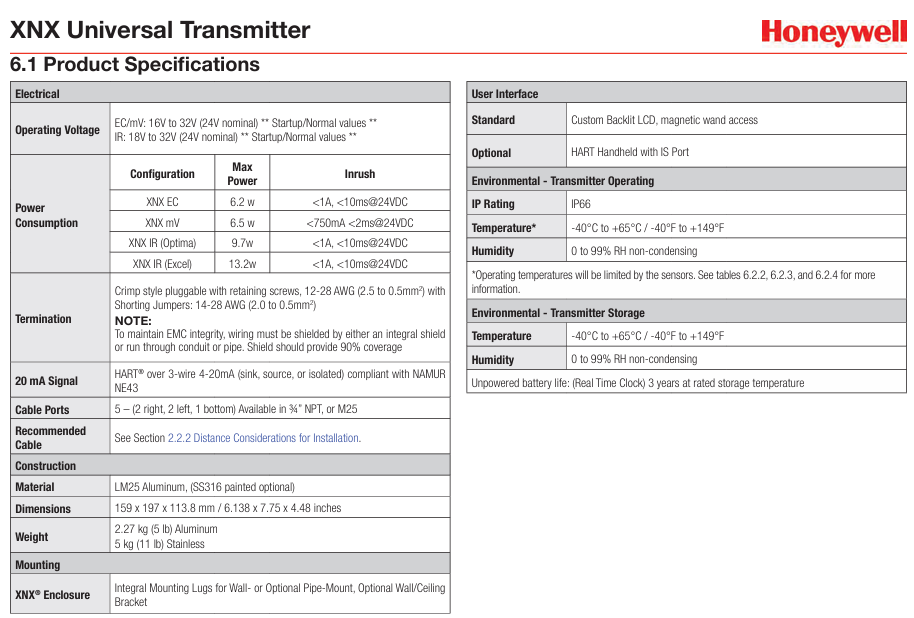

Electrical specifications

Working voltage: EC/mV type is 16-32VDC (nominal 24VDC), IR type is 18-32VDC (nominal 24VDC).

Power consumption: varies depending on the configuration, such as XNX EC with a maximum of 6.2W and XNX IR (Excel) with a maximum of 13.2W.

Output load: 4-20mA output. The total load resistance should be less than 500 Ω, with a minimum of 200 Ω.

Environmental specifications

Working temperature: -40 ° C to+65 ° C (-40 ° F to+149 ° F).

Humidity: 0 to 99% RH (non condensing).

IP rating: IP66.

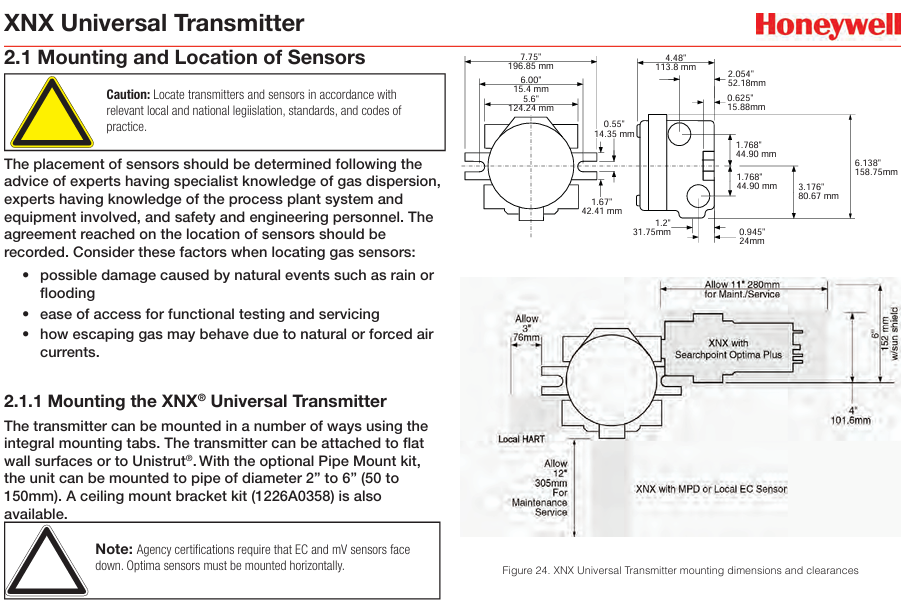

Physical specifications

Shell material: LM25 aluminum alloy (optional 316 stainless steel coating).

Size: 159 x 197 x 113.8 mm (6.138 x 7.75 x 4.48 inches).

Weight: Approximately 2.27kg (5lb) for aluminum alloy and 5kg (11lb) for stainless steel.

Warning and malfunction

Warning message: including power failure, abnormal temperature, calibration requirements, etc., detailing the applicable sensors, characteristics, and solutions for each warning.

Fault information: covering sensor faults, communication faults, internal faults, etc. Each fault has corresponding fault codes, characteristics, event history data, and solutions.

Information message: Record operation and status information such as forced relay mode startup, successful calibration, etc.

Certification and Warranty

Certification: Passed multiple certifications such as UL, CSA, FM, ATEX, IECEx, etc., suitable for different hazardous areas.

Warranty: XNX Universal Transmitter (excluding consumables) is covered by a 36 month warranty, XNX electrochemical sensor is covered by a 12 month warranty (from self commissioning or shipment, whichever comes first), and multi-purpose detector is covered by an 18 month warranty (from shipment).

Appendix Information

The HART protocol introduces the communication modes (point-to-point, multi station), wiring methods, device descriptor files, and operation menus of the HART interface.

Modbus protocol: describes the communication parameters, register definitions, and usage examples of the Modbus interface.

Control drawings: Wiring and installation drawings for different certified versions (UL/INMETRO, UL/CSA/FM, etc.) are provided.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands