Welcome to the Industrial Automation website!

Product

Article

NameDescriptionContent

当前位置:

Eaton XV-102 Touch Screen Display

Eaton operates an independent development center, the ‘Cybersecurity Center of Excellence’ (CCoE), specifically designed to combat the threats posed by cyber attacks. All Eaton products are regularly qualified for secure operation.

The XV-102 devices with an Embedded Linux operating system seamlessly integrate into Eaton CCoE’s ‘Defense in Depth’ cybersecurity concept. The devices boot from a write protected memory, and only operating system software updates signed by Eaton can be installed on the devices. All device settings and interfaces are secured via password entries, which also withstand a brute force attack.

Communication channels can be selectively activated and encrypted for the required tasks. However, cybersecurity and usability are not mutually exclusive. Guided by the first-boot agent, the prepared application software and device configuration are installed easily and efficiently via a USB memory during machine or system commissioning. The application software and process data can optionally be installed on an encrypted SD card, and in the event of a device replacement, the application-specific data can simply be taken over to the replacement device.

The XV-102 devices with an Embedded Linux operating system seamlessly integrate into Eaton CCoE’s ‘Defense in Depth’ cybersecurity concept. The devices boot from a write protected memory, and only operating system software updates signed by Eaton can be installed on the devices. All device settings and interfaces are secured via password entries, which also withstand a brute force attack.

Communication channels can be selectively activated and encrypted for the required tasks. However, cybersecurity and usability are not mutually exclusive. Guided by the first-boot agent, the prepared application software and device configuration are installed easily and efficiently via a USB memory during machine or system commissioning. The application software and process data can optionally be installed on an encrypted SD card, and in the event of a device replacement, the application-specific data can simply be taken over to the replacement device.

Eaton XV-102 Touch Screen Display

An Eaton secure by-design solution

Eaton operates an independent development center, the ‘Cybersecurity Center of Excellence’ (CCoE), specifically designed to combat the threats posed by cyber attacks. All Eaton products are regularly qualified for secure operation.

The XV-102 devices with an Embedded Linux operating system seamlessly integrate into Eaton CCoE’s ‘Defense in Depth’ cybersecurity concept. The devices boot from a write protected memory, and only operating system software updates signed by Eaton can be installed on the devices. All device settings and interfaces are secured via password entries, which also withstand a brute force attack.

Communication channels can be selectively activated and encrypted for the required tasks. However, cybersecurity and usability are not mutually exclusive. Guided by the first-boot agent, the prepared application software and device configuration are installed easily and efficiently via a USB memory during machine or system commissioning. The application software and process data can optionally be installed on an encrypted SD card, and in the event of a device replacement, the application-specific data can simply be taken over to the replacement device.

XV-102 Touch Display - Compact, powerful and flexible

The XV-102 touch display range from Eaton’s MoellerTM Series offers a compact, powerful and flexible solution for automation applications where space is at a premium. The devices offer the modern, future-proof Embedded Linux operating system with advanced cyber security features and even faster processors, while maintaining form, fit and function. They can be used either as HMI operating panels or optionally with integrated PLC functionality.

Thanks to the resistive touch screen, the devices can be operated with thick work gloves and are extremly robust against electrical interferences. The XV-102 devices are equipped with electronics, based on state-of-the-art industrial components with high availability.

With the help of the powerful CPU (Central Processing Unit or main processor), the easy-to-learn GALILEO visualization software, including an extensive library of operating objects, the touch panels make it possible to quickly implement efficient control interfaces.

In addition, visually appealing screen displays can be quickly implemented to further emphasize the high quality of the machine.

Embedded Linux was specially developed for embedded systems in the context of modern machine automation.

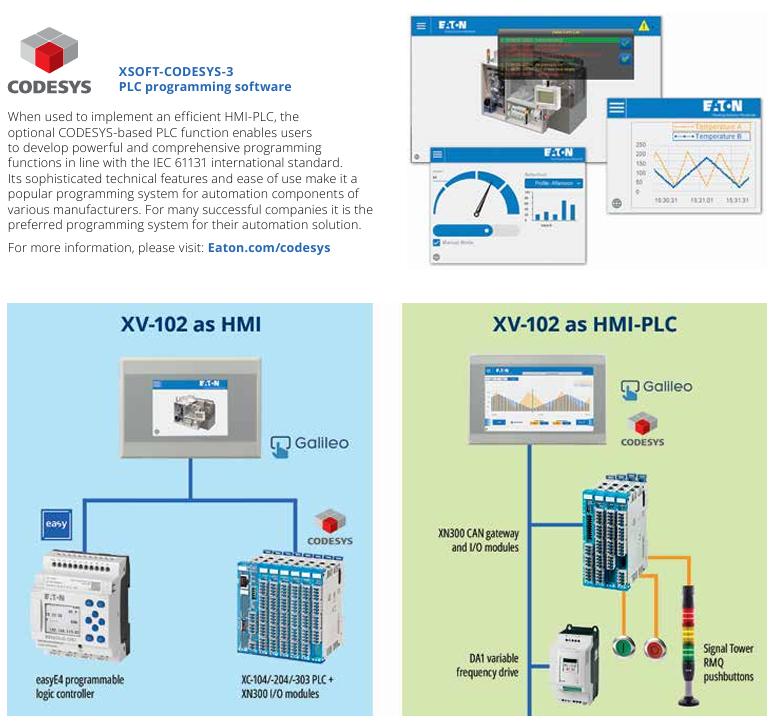

It makes the devices future-proof, particularly in terms of cyber security. As before, PLC programming is carried out using CODESYS, the established and industry-wide standard for programming control systems.

The devices are housed in a plastic casing and can also be used in portrait format. The integrated non-volatile memory can be easily expanded via an SD card, if required. In addition to the Ethernet interface, CANopen, RS232 and RS485 interfaces are also available, depending on the device type.

At a glance

• Screen sizes include 3.5-inch-, 5.7-inch- (4:3 format) and 7.0-inch variants (16:9 format)

• Resistive touch technology

• 800 MHz ARM CPU

• SD card slot, USB-Host

• Ethernet and optional CANbus, RS485 and RS232 interfaces

• Programming with GALILEO V11, optionally with XSOFT-CODESYS 3

• Approvals: UL, DNV

GALILEO 11 visualization software

Galileo is an intuitive and powerful engineering environment that takes small effort to master and meets every requirement involved in today‘s on-site machine operation. It is custom tailored to the needs of the international machine and systems building industry and reflects the latest developments in visualization technology.

The comprehensive integrated communication protocols make it possible to provide visualization for all common PLCs resp. controllers.

Visualization controls like value display, gauge, graph charts, lists and many more offers great design possibilities for visualizing PLC tag values. At the same time, controls like value entry with modern looking on-screen keyboard, slider, list selection box, recipe and more facilitate the changing of PLC variables.

Navigation between the different visualization visualization image pages can be designed attractively using animated screen changes, pull-out menus and dynamic dialogs. Additional functionalities like scripting, trigger script execution on events and a built-in user management complete the broad range of

customization.

The possibility to create your own user defined controls with parameter interface (tags, text, images, script assignments,…) improves reusability and graphical consistency across the project, saving time during the development phase.

By activating the web visualization functionality of Galileo, remote devices such as PC’s, tablet’s or smartphones can easily access the XV-102 visualization. Based on the HTML5-standard all common web browsers (Safari, Chrome, Edge) are supported.

It is possible to make an existing visualization web-accessible

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands

231

+86-153-9626-8993

WeChat

Contact

Whatsapp

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Product

Copyright © 2023 KongJiang Group All Rights Reserved .